- 168 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Managing Project Supply Chains

About this book

The success of any project relies on the punctual, accurate and cost-effective delivery of materials, systems and facilities. Typically, a major project involves several stakeholders working together with controlled resources to deliver a completed project. It has many suppliers, contractors and customers; it has procurement and supply, demand planning and scheduling; it often lasts several years and has long lead times. Managing Project Supply Chains demonstrates how customised supply chain management can be applied to project management, ensuring project resources are delivered as required, reducing delays and costs and promoting a successful outcome.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

CHAPTER 1

THE ROLE OF SUPPLY CHAIN AS A VALUE DRIVER

Introduction

This chapter explains the basic concepts of Supply Chain Management (SCM) and shows that supply chains in some shape or form are required to deliver products and services that either we – or our organisation – need or think are needed. For every business transaction there is a supplier and a customer and there are activities, facilities and processes linking that supplier to the customer. In addition, for every task in a project there is a customer and a supplier or a group of suppliers. The management process of balancing these links to deliver best value to the customer at minimum cost and effort for the supplier is supply chain management. Whilst you may be unaware of them, you will experience supply chains everywhere, e.g. in running your home, managing a manufacturing business, in health services, hotels, banks, government, utilities, non-profit organisations, universities, entertainment, retail, professional services and managing a project.

Supply chains vary significantly in complexity and size but their fundamental principles apply to all operations, whether they are large or small, manufacturing or service, private or public sector. Supply chain management is relevant to all businesses and to all operations.

Let us look at some everyday scenarios to see supply chains in operation. When a customer visits a hairdresser she is the customer and the hairdresser is the supplier. The hairdresser will need to ensure the availability of materials (shampoo, conditioner and colouring), facilities and equipment (chairs, driers etc.). In order to provide the service, the hairdresser is involved with purchasing, inventory management and facilities supervision. In order to minimise customer queues there is also a need for demand forecasting, capacity management, scheduling and quality management. In this example of a basic service operation we can identify the key components of supply chain management.

Take another scenario. Consider that you are checking in at Zagreb Airport for a return flight to London. You are unhappy to find that there is a long queue. You have discovered that in addition to normal procedures the central computer is down and a screening machine has been installed to X-ray all types of luggage as an extra security precaution. In this case the supply chain is obviously more complex than the example shown above for the hairdressing service. For you the customer, the initial focal point is the check-in clerk, but there are many supporting links leading to this provision. The airlines have to sell tickets, ensure the availability of aircraft with all the required fittings (including in-flight entertainment systems) in an acceptable condition, provide meals and a have a stock of trained air crew available. Before you got to Zagreb Airport your administration manager will have purchased a ticket from a travel agent, who in turn may have made an electronic booking.

In this case, we can see that there are suppliers and suppliers of suppliers. Moreover there exist both customers and customers of customers. However the basic functions of forecasting, capacity management, inventory management, scheduling and quality management are present just as they were with the hairdresser, and just as they are for any supply chain.

The message is clear: the key objective of supply chain management is to provide best value to the customer by measuring, planning and managing all the links in the chain.

In a major project the client may engage only the main contractor, who in turn will select the second tier contractors. In succession they will procure a wide range of works, services and materials from the large number of smaller contractors and suppliers which form the Project Supply Chain of sourcing and delivery.

WHAT IS SUPPLY CHAIN MANAGEMENT?

In a typical supply chain, raw materials are procured and items are produced at one or more factories, shipped to warehouses for intermediate storage and then transported to retailers or customers. If you asked people involved in business to define the term ‘supply chain’ you would get many different answers. Each definition would reflect the nature of the individual’s business and the inputs and outputs produced. For some, supply chain is related to purchasing and procurement; to others it involves warehousing, distribution and transportation. For yet others it would be sources of capital and labour. Swink et al. (2010) provide a holistic definition of the supply chain, viz. the entire network of organisations involved in:

• converting raw materials and information into products and services;

• consuming the products and services;

• disposing of the products and services.

They further state that ‘this definition treats the supply chain as a product cradle-to-grave concept, including all value-added activities required to plan, source, make and deliver products and services that meet customer needs.’ To this we can add the word ‘process’. We see the supply chain not as a series of separate operations and organisations but as a complete end-to-end procedure.

Another useful definition is provided by Simchi-Levi et al. (2003, p. 1):

Supply chain management is a set of approaches utilized to efficiently integrate suppliers, manufacturers, warehouses and stores, so that merchandise is produced and distributed at the right quantities, to the right locations, and at the right time, in order to minimize system-wide costs while satisfying service level requirements.

What do these definitions suggest? They propose that supply chain management must consider every organisation and facility involved in making the product, and the costs inherent in doing so. This also implies that the objective is to be cost effective across the whole supply chain, which requires a system wide approach to optimisation.

Supply Chain in Manufacturing

Supply chain management in a manufacturing and supply organisation considers the demand, supply and inventory needs for each item of production. In particular it looks at how inventory flows through the system in order to achieve output to the customer’s specification on time and at the least cost. With supply chain management, customer service is increased through the reduction of lead times, and the product is always exactly as specified and is always delivered on time. Costs are reduced through the elimination of any activity that does not add value and through the reduction of inventories of material and associated holding and handling costs.

Activities and measures based on customer requirements are very significant in improving business performance. However, externally driven customer-based measures have to be matched by gauges of what the company can do (feasibility, capacity, know-how and resources) to consistently meet customer expectations. A high standard of customer performance derives from planning, processes and actions integrated across the whole organisation.

Supply chain management focuses on the critical measures of all elements of the supply chain. Externally these measures include the suppliers at one end and the customer at the other end of the supply process. These externals, the supplier and the customer, are matched with the internal requirements of the manufacturing process. The focus is two-fold: to satisfy customer needs and to keep costs down to a minimum.

In reality the elements of supply chain management are not new – we all have been dealing with parts of the supply chain for years (e.g. buying, planning, scheduling, stock control, warehousing, logistics, distribution etc.) without realising the significance of the whole chain concept. Likewise the cost of the various elements of supply and distribution has been long recognised. ‘In 50 years between 1870 and 1920 the cost of distributing necessities and luxuries has nearly trebled, while production costs have gone down by one fifth – what we are saving in production we are losing in distribution’, observed Ralph Barsodi in 1929.

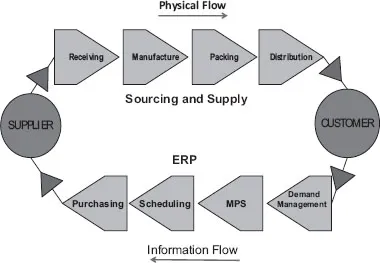

It is relatively new to view the supply chain as a process, in other words as a single integrated flow across all the functions of a business. Traditionally activities within a supply chain were seen as separate and specialist functions such as purchasing, planning, scheduling, manufacturing and distribution. However with supply chain management, the flow of both materials and information across traditional functional boundaries is seen as a single process. These flows are depicted in a simplified model in Figure 1.1.

In the past, information flow was the domain of the commercial division, while the conversion process of materials flow constituted a manufacturing or technical division task. With an integrated supply chain approach the responsibility for all elements of supply now lies with Operations Management or supply chain management. In many businesses, the integrated approach is being extended to include all suppliers (including ‘upstream’ 1st, 2nd and 3rd tier suppliers) through the manufacturing process ‘downstream’ to each level of customers. This includes distributors, wholesalers and retailers through to the end user or consumer. This is known as the ‘extended supply chain’.

Figure 1.1 Supply chain management model

Supply Chain in Services

Thanks to ease of travel, the media and the World Wide Web customers have never been more informed than they are today. Customers know what they want and are aware of what can be done; they understand the concept of world-class and continuous improvement. This is especially true in service industries. As a result of the heightened expectations of these clients, operations managers in service sectors have been forced to focus their attention on managing the complete value-adding system using the principles of supply chain management.

But just how can service industries apply supply chain management? The supply chain of a service organisation contains suppliers, products or services, customers and their demand for products and service level agreements. Service inventory can be in the form of information databases, stocks of consumables (as with the hairdresser), stationery items (such as brochures and promotional material), and subcontractors (including facility managers, travel agents, caterers and advertising agencies).

Swank (2003) described a successful application of supply chain management and lean production principles in a typical insurance service company in the USA, Jefferson Pilot Financial (JPF). JPF believed that the processing of their almost tangible ‘service product’ was comparable to a car assembly process. Swank explains that: ‘Like an automobile on the assembly line, an insurance policy goes through a series of processes, from initial application to underwriting or risk assessment to policy issuance. With each step value is added to the work in progress – just as a car gets doors or a coat of paint’ (p. 124).

Supply Chain in Not-for-profit Organisations

The good practices of supply chain management can be adapted to provide major practical benefit to not-for-profit organisations, such as charities, in meeting their objectives. International disasters have a huge impact on the world’s population, increasing the need for aid groups to improve their logistics capability and capacity. Perhaps the biggest impact of supply chain management in not-for-profit organisations is responding to unpredictable demands through quick-response supply and distribution.

The world events of 2005 have suggested that humanitarian organisations are yet to fully exploit supply chain optimisation. For example, referring to the Hurricane Katrina disaster in New Orleans, Waller (2005) was not surprised that Wal-Mart, the world’s largest retailer, beat the Federal Emergency Management Agency (FEMA) and the Red Cross to areas devastated by the hurricane. He said the company delivered supplies quickly and efficiently because that is what it does every day. Wal-Mart is the master of supply chain management, and the company’s expertise in this area worked well during a natural disaster.

An example of the application of supply chain management in a not-for-profit organisation is the National Health Service in the United Kingdom.

Supply Chain in Projects

The essential success criterion of a project is the timely, accurate to quality and cost-effective delivery of materials, systems and facilities. There are many stakeholders, contractors and suppliers involved in a project. In a major infrastructure scheme such as Heathrow Terminal 5 there are likely to be more than 100 key contractors and consulting firms. Thus, supply chain management methodologies and processes are crucial to ensuring that project resources are delivered as required.

Although supply chain management should be an essential process within the Project Manager’s tool kit, its importance in Project Management is not properly recognised. Due to the perception of the ‘one-off’ and unique nature of a project versus the repetitive nature of operations, the traditional approach of project management has been consciously different from that of operations management. Supply chain management is inextricably linked with operations management (Slack et al. 2006, p. 208). A primary objective of both supply chain management and operations management is to ensure optimum customer service by balancing cost, time and quality (Wild, 2002). Howev...

Table of contents

- Cover

- Half Title

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- List of Figures

- List of Tables

- About the Author

- Acknowledgements

- Glossary

- 1 The Role of Supply Chain as a Value Driver

- 2 The Building Blocks of a Project Supply Chain

- 3 Project Planning Chain

- 4 Project Delivery Chain

- 5 Supply Chain Integration: Systems and Procedures

- 6 Supply Chain Integration: Quality and Performance Management

- 7 Supply Chain Integration: Regular Reviews

- 8 Lean and Agile Project Supply Chain

- 9 Implementation: Making it Happen

- References

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Managing Project Supply Chains by Ron Basu in PDF and/or ePUB format, as well as other popular books in Business & Business General. We have over one million books available in our catalogue for you to explore.