Chapter 1

Advances in High-Strength Fibers Based on Nylon-Clay Nanocomposites

Takeshi Kikutani,a Rouhollah Semnani Rahbar,b and Shahin Kazemic

a Department of Materials Science and Engineering, School of Materials and Chemical Technology, Tokyo Institute of Technology, Tokyo, Japan

b Textile and Leather Research Group, Faculty of Chemistry and Petrochemical Engineering, Standard Research Institute, Karaj, Iran

c Department of Textile Engineering, Amirkabir University of Technology, Tehran, Iran

In the first part of this chapter, basic characteristics of nylon 6/clay nanocomposite fibers are summarized, reviewing recently published papers. Introduction of clay into nylon 6 improves various properties. Thermal stability and flame retardancy can be improved to a certain extent; abrasion and wear resistance can be improved with only a small amount of clay, probably because of good adhesion between nylon 6 and clay; and dyeability can be improved when nylon 6 is dyed with disperse dye. Reported mechanical properties vary significantly among research groups and used materials. In general, on comparing nylon 6/clay fibers with nylon 6 fibers, it can be said that there can be about 10%–20% increase in the tensile modulus, while any noticeable improvement cannot be expected for the tensile strength. In the second part of this chapter, the effect of the incorporation of clay into nylon 6 on fiber formation behavior is presented. The crystallization rate in the quiescent state increases with the addition of clay, especially under high-cooling-rate conditions. In the high-speed melt spinning process of nylon 6/clay hybrid (NCH) fibers, orientation-induced crystallization can be promoted, which causes a significant increase in the tensile modulus of as-spun fibers. Improvement of dimensional stability, that is, no crystallization-induced spontaneous elongation after spinning, is another unique characteristic of the high-speed-spun fibers. Mechanical properties can be improved significantly through the application of the in-line drawing process. The highest tensile modulus and strength of the in-line drawn fibers was 10 GPa and 1000 MPa, respectively, while those values for high-speed-spun fibers was 2.5 GPa and 300 MPa. In the high-speed bicomponent spinning of nylon 6 and an NCH, the NCH showed sufficiently high molecular orientation, while that of nylon 6 was negligible. Different thinning behaviors of nylon 6 and the NCH in the single-component spin-line of an individual material can be the origin of such peculiar structure development behavior.

Nanocomposites are an emerging class of organic/inorganic hybrid materials showing remarkable performance for multifunctional applications and have attracted great interest both in industry and in academia. They are defined by the size of dispersed particles having at least one characteristic dimension less than 100 nm [1].

Owing to wide use of polyamide 6 (nylon 6) in plastic and fiber industries, nylon 6 nanocomposites have been characterized in many studies. Several types of nanofillers, including layered silicates (clay), carbon nanotubes, carbon nanofibers, graphite nanoplatelets, metal oxide nanoparticles (TiO2, ZnO, SiO2, and so on), and hybrid nanostructured materials (polyhedral oligomeric silsesquioxanes) were incorporated in the nylon 6 polymer matrix [2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16]. Much research has focused on the modification of polyamide with layered silicates. On incorporating nanoclay into the nylon 6 polymer matrix, the following modifications were observed: improvement in thermal stability, reduction in the rate of heat release and enhancement of char formation in a fire, improvement of mechanical properties, and improved gas barrier performance [9, 17, 18, 19, 20, 21, 22].

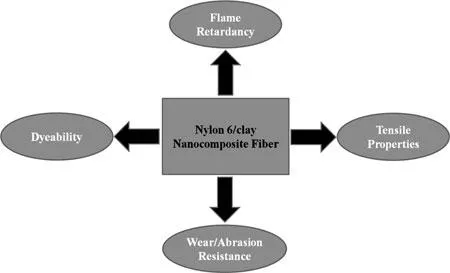

In contrast to nylon 6 nanocomposites, not much research work could be found in the open literature regarding the spinning and characterization of nylon 6/clay nanocomposite fibers [23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 47]. When compared with neat nylon 6 fibers, nylon 6/clay nanocomposite fibers have some superior properties (Fig. 1.1). These properties are enhanced tensile modulus and strength, improved dyeability, better flame retardancy, superior abrasion, and wear resistance. A review of the work being done in the area of nylon 6/clay nanocomposite fibers will be discussed in the next section as a function of fiber performance. In the section after that, the mechanism of fiber formation of nylon 6/clay nanocomposites will be discussed on the basis of the experimental results obtained in our laboratory.

1.2 Review on Research for Nylon 6/Clay Hybrid

1.2.1 Flame Retardancy/Thermal Stability

One of the most important challenges in the application of textile and polymers is their flammability. To improve textile and polymer flame retardancy, various nanofiller/conventional flame retardants have been already developed. The major challenges for the conventional-flame-retardant-incorporated nylon 6 fiber processing are:

• Deterioration in the mechanical properties

• High production costs and processing difficulties due to addition of high flame-retardant filler content (of 30–60 wt%)

• Potential leaching of harmful and toxic materials during wear or combustion of flame-retardant textiles [9, 47, 48, 49, 50, 51, 52]

Therefore, there is a need to resolve these issues by finding a better flame-retardant additive for fiber and textiles. According to the literature, clay is an effective flame retardant and widely used in plastics and textiles. It offers an interesting new route for manufacturing flame-retardant textiles with a permanent effect at lower cost and retaining the basic properties of textiles [27, 37, 46, 47, 51, 53].

Bourbigot and coworkers [27, 54] prepared nylon 6/organically modified montmorillonite (OMMT) nanocomposite fibers via the melt spinning process, and then the fabrics were knitted with a surface weight of 1020 g/m2 and a thickness of 2.5 mm. These nanocomposite fabrics were exposed to 35 kW/m2 of heat flux in a cone calorimeter. Bourbigot and coworkers showed that upon inclusion of clay in nylon 6, the peak heat release rate (PHRR) values decreased by 40% against neat nylon 6 and also smoke evolution, particularly CO and CO2 emission, significantly decreased in the nanocomposite fabrics as compared to neat nylon 6 fabric. It should be noted that this reduction in PHRR might not be reflected by apparel fabrics with normal area densities (100–200 g/m2) [55]. Moreover, ignition times of 70 s and 20 s were recorded for the neat and nanocomposite nylon 6 fabrics, respectively. Furthermore, visual assessment of the tested samples showed that the morphology of the char layer formed on the nanocomposite and neat nylon 6 fabrics was different.

Thermogravimetric analysis (TGA) in the air showed that the thermal behaviors of neat nylon 6 and nanocomposite fibers were similar up to 450°C. After 450°C, the nanocomposite fiber had better thermal stability than neat nylon 6. Moreover, there was no sign to confirm that the clay had a destabilizing effect on nylon 6. In 2004, a nylon 6/clay nanocomposite containing 5 wt% of clay was compounded and melt extruded into filaments by McCord and coworkers [29]. They reported that the nanocomposite fiber had a black, charcoal-like residue after burning test whereas neat nylon 6 residue was brownish globules. Moreover, the authors found that the amount of smoke emission decreased in the presence of clay.

In the another research, nylon 6/clay nanocomposite fibers containing 8 wt% and 10 wt% of OMMT were melt-spun and then converted into a knitted fabric [37]. T...