eBook - ePub

Additive Manufacturing Change Management

Best Practices

This is a test

- 160 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Additive Manufacturing Change Management

Best Practices

Book details

Book preview

Table of contents

Citations

About This Book

Additive Manufacturing (AM) has altered manufacturing as we know it, with shortened development time, increased performance, and reduced product costs. Executive management in industry are bombarded by marketing from their competitors showcasing design solutions leveraged through AM. Therefore, executive management ask their project management teams to figure out how to utilize AM within their own company. Clueless on how to approach the problem, managers start learning about AM from experts and become overwhelmed at the highly technical information. Unlike other AM books that focus on the technical output of AM technology, this new book focuses solely on the managerial implementation.

Features

-

- Presents the impacts of AM technology

- Provides engaging, practical, and entertaining "war stories" from the front line of AM industrialization

- Describes in detail, the significant hurdles in AM certification and implementation

- Offers templates of proven change management best practices, as practical solutions

- Omits the technical verbiage that gets in the way of management understanding how the process is implemented

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Additive Manufacturing Change Management by David M. Dietrich, Michael Kenworthy, Elizabeth A. Cudney in PDF and/or ePUB format, as well as other popular books in Negocios y empresa & Gestión. We have over one million books available in our catalogue for you to explore.

Information

section four

Applying change management best practices to additive manufacturing

chapter eleven

Establish a sense of urgency

In order for any new initiative to gain momentum, there must be a sense of urgency or burning platform. This is the same for all corporate level change efforts regardless if it is additive manufacturing (AM) or Lean or Six Sigma. There has to be a recognition that in order to move the company forward, things must change. If status quo is acceptable, then it will be difficult to gain the necessary buy-in for AM adoption. This chapter discusses the importance of and methods for establishing a sense of urgency around AM.

Leading change

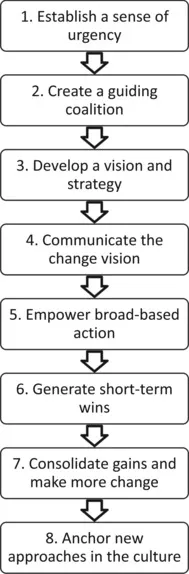

John Kotter [1] developed an eight-step model for leading change, which is provided in Figure 11.1. The next several chapters will discuss how to lead an organization through the change of adopting AM.

Leading AM change throughout a company can be challenging. Management should ask several questions when deciding which AM change efforts are worthwhile:

- What is the evidence that the approach really can produce positive results?

- Is the approach relevant to your company’s strategies and priorities?

- Can you assess the costs and potential benefits?

- Does it really help people add value through their work?

- Does it help the company focus better on customers and what the customers value?

- Can you go through the decision-making process, understand what you are facing, and feel that you are taking the right approach?

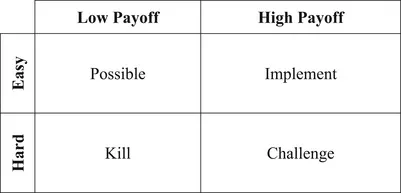

A PICK (Possible, Implement, Challenge, and Kill) chart is an easy way for management to categorize AM change ideas. A PICK chart is a visual tool for organizing and prioritizing ideas. Often after brainstorming session, a PICK chart is used to determine which ideas can be implemented easily with a high payoff. Figure 11.2 provides a PICK chart.

From a management perspective, a PICK chart enables management to compare ideas based on their impact and ease or cost of implementation. Ideas that are easy to do and have a high payoff should be implemented. Ideas that management should consider as possible projects are those that are easy to do but have a low payoff. Ideas that have a high payoff but are hard to do will be a challenge. Management should consider these carefully to determine if they have the resources to accomplish these. Finally, ideas that are hard to do and have a low payoff should not be pursued.

Figure 11.1 Model for leading change [1].

Figure 11.2 PICK chart.

Establishing a burning platform

The first step to leading change is to establish a sense of urgency, or burning platform, within the company itself. Leaders must ask as agents of change in order for change to occur. Creating a sense of urgency is often accomplished by senior leadership through actions that capture attention from organizational stakeholders and communicating the need to quickly respond to a condition. By explaining the need, leaders alert the organization of the need to change and begin preparing all levels of the organization for the change process. The key is communicating the urgency because this leads to cooperation of the affected stakeholders and meaningful change. It is the first and most important step in leading change.

It is not sufficient for leaders to simply request action. Leadership must provide a vision for the value of the future state in order for organizational stakeholders to buy in. Further, leaders must make it clear that maintaining the status quo is not an option and explain why. There must be a compelling narrative that leaders provide to show why the organization cannot remain in its current state. Leaders cannot shy away from open and honest discussions about the current market, competition, and customer environment as well as relevant financials. Data supports the urgency. A lack of transparency, however, can lead to reduced buy-in.

In many cases, your company may be responding to an already existing crisis that necessitates the need for AM adoption. For example, perhaps a competitor is advertising a competing product’s use of AM technology. Or, perhaps your company has lost its sole source supplier of a particular component and the production line will shut down if a part is not available quickly, which was discussed in previous chapters, AM may serve a role in this scenario.

Conversely, your company may only be dabbling in AM technology. Perhaps your company is merely investigating where the technology might fit within your product lines, or perhaps how it may save lead time and cost for your company without a clear goal in mind. In this case, you may need to advocate for a sense of urgency to use AM within your company. Many change agent theorists believe that in order for a new technology to gain a foothold within companies, there needs to be a sense of urgency to deploy it. If no urgency exists, then a lower risk base will naturally hedge toward known technologies with established track records of manufacturing and design performance.

For example, you overhear a conversation between a project manager named Sara and a structural engineer named Johal. Sara claims that management has been lobbying for more AM integration in design; however, Johal seems convinced that AM is a riskier approach because Johal does not have three decades of mechanical property knowledge about how AM will behave from a structural performance standpoint. Johal points out that in order to develop the confidence in the properties, a large battery of destructive testing, that will take months to complete and over $1 million dollars of testing, will need to be performed to establish a basis for Johal to cover his ass. Johal exemplifies Elon Musk’s quote of “There’s a tremendous bias against taking risks. Everyone is trying to optimize their ass-covering.” Sara takes Johal’s message of restraint back to executive management, who not knowing better, take Johal at his word and kills any AM initiative due to being cost prohibitive.

Now, alternatively consider if the product that Johal is responsible for analyzing is being discontinued due to lack of sales and now Johal will find himself without a job in the near future because a competitor released a higher performing, lighter weight, competing product. Do you think that Johal could find an alternative way to certify an AM offering in those conditions? Perhaps quickly building and destructively testing an AM component or components to empirically feed into structural analysis models? Johal would probably find a way given Johal’s job is now on the line. This scenario is what is meant by establishing a sense of urgency.

So, how does one go about communicating a sense of urgency? Luckily, there are several steps that leaders can use to create a sense of urgency and increase buy-in. First, leaders should show their commitment to the change by providing adequate resources, training, and time. In order for AM to be successfully adopted, employees must be trained and given the appropriate equipment and tools. By outlining a strategy for rolling out an AM training program, the leaders are showing their support and commitment. It also indicates that this will not be a passing fad, rather it will be a new business approach. Second, leaders must have open lines of communication. This means sharing the good news and the bad news.

There are several specific approaches to enlisting AM cooperation, which will enable a smoother implementation. These approaches include education and awareness, negotiation and reward, manipulation and co-optation, explicit and implicit coercion, facilitation and support, and participation and involvement as shown in Figure 11.3.

In order for an AM implementation to be successful, management must offer education and increase awareness of AM technology. First, training programs on AM must be rolled out that are targeted for employees at all levels of the organization. For example, while finance is not directly involved in production, they will need to understand the impact of AM on supplies, materials, and equipment. Organizations should also consider multifunctional technical and nontechnical-based certifications to encourage interest in increasing AM knowledge.

Management must also consider employee participation and involvement. Companywide initiatives to utilize AM through linking implementation to department metrics and goals will show management’s commitment to AM. For example, organizations can set goals which require a certain monetary target of value add using AM per new product development program. Conversely, management must also provide funding for equipment and training for departments to realize these goals. As such, senior management must develop a facilitation and support plan for AM capital. Internal research and development budgets must be dedicated for AM to address technical gaps.

Figure 11.3 Approaches to enlisting AM cooperation.

To encourage the adoption of AM by program and individuals, management must also consider negotiation and rewards. For example, a top-down-driven, reward-based programs can encourage employees to drive AM adoption in their business unit or department. For AM “nonbelievers,” management may need to consider manipulation and co-optation to bring these individuals into successful AM teams and transition their thinking. This can also be accomplished by highlighting competitors’ successes with AM. While this requires explicit and implicit coercion, it can be accomplished often times by showcasing how a lack of AM adoption will impact bottom-line business.

Business strategy tools

In addition, there are business strategy tools that are commonly used that can assist with establishing a sense of urgency and risk assessment. While it is important to identify opportunities for improvement, it is also critical to assess and mitigate risks. Risks can be threats and opportunities and should be addressed through actions to avoid, mitigate, acknowledge, or accept these risks. Tools and techniques that can help identify and mitigate risks include decision trees, Strengths, Weaknesses, Opportunities, and Threats (SWOT) analysis, and risk grids.

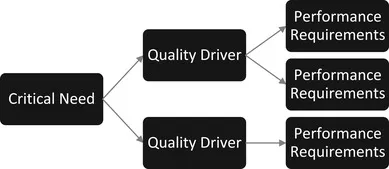

Figure 11.4 Tree diagram.

Decision trees are a decision-making tool that illustrates decisions and their possible consequences. In particular, they are useful for clarifying choices, risks, objectives, monetary gains, and information needs. These diagrams are drawn from left to right using decision rules in which the outcome and the conditions form a conjunction using an “if” clause. Generally, the rule has the following form (as shown in Figure 11.4):

if condition1 and condition2 and condition3 then outcome.

A SWOT analysis is a structured approach to evaluating a product, process, or service in terms of internal and external factors that can be favorable or unfavorable to their success. Strengths and opportunities (SO) ask “How can you use your strengths to take advantage of these opportunities?” Strengths and threats (ST) ask “How can you take advantage of your strengths to avoid real and potential threats?” Weaknesses and opportunities (WO) ask “How can you use your opportunities to overcome the weaknesses you are experiencing?” Weaknesses and threats (WT) ask “How can you minimize your weaknesses and avoid threats?” An example of a SWOT analysis is shown in Figure 11.5.

Next, let’s apply the SWOT analysis approach to a typical AM challenge companies may face when first beginning their AM journey. Let’s consider that we work for a small vehicle light manufacturing company. This company makes police, fire and ambulance lights for emergency responders and sells their product globally. The team wants to establish a sense of urgency to create a change in the company to implement AM into their company. The high...

Table of contents

- Cover

- Half Title

- Continuous Improvement Series

- Title Page

- Copyright Page

- Contents

- Foreword

- Preface

- Acknowledgments

- Authors

- Introduction

- Section I: Additive manufacturing background and potential

- Section II: Creating and managing additively manufactured change

- Section III: Additive manufacturing barriers

- Section IV: Applying change management best practices to additive manufacturing

- Index