- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Timber: Its Nature and Behaviour adopts a materials science approach to timber and comprehensively examines the relationship between the performance of timber and its structure. This book explains a wide range of timbers physical and mechanical behaviour (including processing) in terms of its basic structure and its complex interaction with moisture. The performance of timber and panel products is also related to the levels set in new European specifications and with the associated methods of testing.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Structure of timber

1.1 Introduction: timber as a material

From earliest recorded times timber has been an ubiquitous material; the ancient Egyptians produced furniture, sculptures, coffins and death masks from it as early as 2500 BC; elaborate wooden couches and beds were produced in the days of the Greek empire (700 BC). The Ancient Briton, somewhat less sophisticated in his requirements, used wood for the handles of his weapons and tools and for the construction of his huts and rough canoes. Considerably more diversity in utilisation appeared in Medieval times when, in addition to the use of timber for the longbow, and later the butt of the crossbow and the chassis of the cannon, timber found widespread use in timber-frame housing and boats; musical instrument manufacture based on wood advanced significantly during this period.

In the industrial era of the nineteenth century timber was used widely for the construction not only of roofs but also of furniture, waterwheels, gearwheels, rails of early pit railways, sleepers, signal poles, bobbins and boats. The twentieth century has seen an extension of its use in certain areas and a decline in others, due to its replacement by newer materials. Despite competition from the lightweight metals and plastics, whether foamed or reinforced, timber continues to be used on a massive scale.

World production of timber in 1993 (the last year for which complete data is available) was 3400×106 m3. As much as 55% of this volume (1880×106 m3) is used as fuelwood, and only 1520×106 m3 is used for industrial and constructional purposes.

In 1997, the UK consumed 48.3×106 m3 of timber, panels, paper and pulp based on an underbark wood raw material equivalent basis (Anon, 1998); this was equivalent to a per capita annual consumption of 0.82 m3. Consumption of timber and wood-based panels on a wood raw material basis was 27.07×106 m3 comprising 17.48×106 m3 of softwood, 1.86×106 m3 of hardwood, and 7.73×106 m3 of wood-based panels.

About 80% of consumption is met by imports; the cost of these for timber and wood-based panels (after deduction of a small volume of re-exports) was £4843 million, a far from insignificant import bill and one that is more than 15% of the total UK annual trade deficit.

The remaining 20% of consumption is met from home production, equivalent to 5.51×106 m3 with a value of about £900 million. Although this contribution will increase steadily until about 2020, it is then expected to peak at a value corresponding to only 25% of expected consumption.

In the UK, timber and timber products are consumed by a large range of industries, but the bulk of the material continues to be used in construction, either structurally, such as roof trusses or floor joists (about 43% of total consumption), or non-structurally, such as doors, window frames, skirting boards and external cladding (about 9% of total consumption). The construction industry, therefore, consumed in 1997 timber and wood-based panels to a value of about £3000 million. On a volume basis, annual consumption continues to increase slightly and there is no reason to doubt that this trend will be maintained in the future, especially with the demand for more houses, the increasing price of plastics, the favourable strength-weight and strength- cost factors of timber and panel products, and the increased emphasis on environmental performance and sustainability in which timber is the only renewable construction material.

Timber is cut and machined from trees, themselves the product of nature and time. The structure of the timber of trees has evolved through millions of years to provide a most efficient system which will support the crown, conduct mineral solutions and store food material. As there are approximately 30 000 different species of tree, it is not surprising to find that timber is an extremely variable material. A quick mental comparison of the colour, texture and density of a piece of balsa and a piece of lignum vitae, used to make playing bowls, will illustrate the wide range that occurs. Nevertheless, man has found timber to be a cheap and effective material and, as we have seen, continues to use it in vast quantities. However, he must never forget that the methods by which he utilises this product are quite different from the purpose that nature intended and many of the criticisms levelled at timber as a material are a consequence of man's use or misuse of nature's product. Unlike so many other materials, especially those used in the construction industry, timber cannot be manufactured to a particular specification. Instead the best use has to be made of the material already produced, though it is possible from the wide range available to select timbers with the most desirable range of properties. Timber as a material can be defined as a low-density, cellular, polymeric composite, and as such does not conveniently fall into any one class of material, rather tending to overlap a number of classes. In terms of its high strength performance and low cost, timber remains the world's most successful fibre composite.

Four orders of structural variation can be recognised—macroscopic, microscopic, ultrastructural and molecular—and in subsequent chapters the various physical and mechanical properties of timber will be related to these four levels of structure. In seeking correlations between performance and structure it is tempting to describe the latter in terms of smaller and smaller structural units. Although this desire for refinement is to be encouraged, a cautionary note must be recorded, for it is all too easy to overlook the significance of the gross features. This is particularly so where large sections of timber are being used under practical conditions; in these situations gross features such as knots and grain angle are highly significant factors in reducing performance.

1.2 Structure of timber

1.2.1 Structure at the macroscopic level

The trunk of a tree has three physical functions to perform: first, it must support the crown, the region responsible for the production not only of food but also of seed; second, it must conduct the mineral solutions absorbed by the roots upwards to the crown; lastly, it must store manufactured food (carbohydrates) until required. As described in detail later, these tasks are performed by different types of cell.

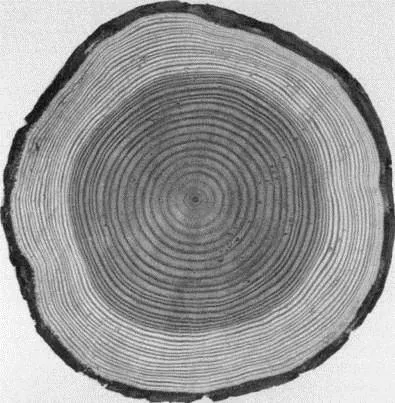

Whereas the entire cross-section of the trunk fulfils the function of support, and increasing crown diameter is matched with increasing diameter of the trunk, conduction and storage are restricted to the outer region of the trunk. This zone is known as sapwood, whereas the region in which the cells no longer fulfil these tasks is termed the heartwood. The width of sapwood varies widely with species, rate of growth and age of the tree. Thus, with the exception of very young trees, the sapwood can represent from 10% to 60% of the total radius, though values from 20% to 50% are more common (Figures. 1.1 and 1.2); in very young trees, the sapwood will extend across the whole radius.

The advancement of the heartwood to include former sapwood cells results in a number of changes, primarily chemical in nature. The acidity of the wood increases slightly, though certain timbers have heartwood of very high acidity. Substances, collectively called extractives, are formed in small quantities and these impart not only colouration to the heartwood, but also resistance to both fungal and insect attack. Different substances are found in different species of wood and some timbers are devoid of them altogether. This explains the very wide range in the natural durability of wood, as discussed further in Section 8.3.1. Many timbers develop gums and resins in the heartwood while the moisture content of the heartwood of most timbers is appreciably lower than that of the sapwood in the freshly felled state. However, in exceptional cases high moisture contents can occur in certain parts of the heartwood. Known as wetwood, these zones are frequently of a darker colour than the remainder of the heartwood and are thought to be due to the presence of micro-organisms which produce aliphatic acids and gases (Ward and Zeikus, 1980; Hillis, 1987).

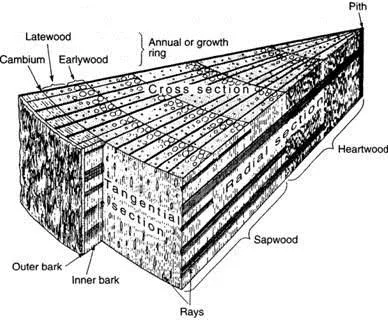

Figure 1.1 Diagramatic illustration of a wedge-shaped segment cut from a 5-year-old hardwood tree, showing the principal structural features. (© BRE.)

With increasing radial growth of the trunk, commensurate increases in crown size occur, resulting in the enlargement of existing branches and the production of new ones; crown development is not only outwards but upwards. Radial growth of the trunk must accommodate the existing branches and this is achieved by the structure that we know as the knot. If the cambium of the branch is still alive at the point where it fuses with the cambium of the trunk, continuity in growth will arise even though there will be a change in orientation of the cells. The structure so formed is termed a green or live knot (Figure 1.3). If, however, the cambium of the branch is dead, and this frequently happens to the lower branches, there will be an absence of continuity, and the trunk will grow round the dead branch, often complete with its bark. Such a knot is termed a black or dead knot (Figure 1.4), and will frequently drop out of planks on sawing. The grain direction in the vicinity of knots is frequently distorted and in a later section the loss of strength due to different types of knots will be discussed.

1.2.2 Structure at the microscopic level

The cellular structure of wood is illustrated in Figures. 1.5 and 1.6. These three- dimensional blocks are produced from micrographs of samples of wood 0.8× 0.5×0.5 mm in size removed from a coniferous tree (Figure 1.5), known technically as a softwood, and a broadleaved tree (Figure 1.6), a hardwood. In the softwoods about 90% of the cells are aligned in the vertical axis, whereas in the hardwoods there is a much wider range in the percentage of cells that are vertical (80-95%). The remaining percentage is present in bands, known as rays, aligned in one of the two horizontal planes known as the radial plane or quartersawn plane (Figure 1.1). This means that there is a different distribution of cells on the three principal axes and this is one of the two principal reasons for the high degree of anisotropy present in timber.

Figure 1.2 Cross-section through the trunk of a Douglas fir tree showing the annual growth rings, the darker heartwood, the lighter sapwood and the bark. (© BRE.)

It is popularly believed that the cells of wood are living cells. This is certainly not the case. Wood cells are produced by division of the cambium, a zone of living cells which lies between the bark and the woody part of the trunk and branches (Figure 1.1). In the winter the cambial cells are dormant and generally consist of a single circumferential layer. With the onset of growth in the spring, the cells in this single layer subdivide radially to form a cambial zone some 10 cells in width. This is achieved by the formation within each dividing cell of a new vertical wall called the primary wall. During the growing season these cells undergo further radial subdivision to produce what are known as daughter cells and some of these will remain as cambial cells while others, to the outside of the zone, will develop into bark or, if on the inside, will change into wood. There is thus a constant state of flux within the cambial zone with the production of new cells and the relegation of existing cambial cells to bark or wood. Towards the end of the growing season the emphasis is on relegation and a single layer of cambial cells is left for the winter period.

Figure 1.3 Green or live knot showing continuity in structure between the branch and tree trunk. (© BRE.)

Fig...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Table of Contents

- Preface

- Acknowledgements

- 1 Structure of Timber

- 2 Appearance of Timber in Relation to its Structure

- 3 Mass-Volume Relationships

- 4 Movement in Timber

- 5 Flow in Timber

- 6 Deformation Under Load

- 7 Strength and Failure in Timber

- 8 Durability of Timber

- 9 Processing of Timber

- Further Reading Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Timber by J.M. Dinwoodie in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.