eBook - ePub

Natural Fibers, Biopolymers, and Biocomposites

This is a test

- 896 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Natural Fibers, Biopolymers, and Biocomposites

Book details

Book preview

Table of contents

Citations

About This Book

Natural/Biofiber composites are emerging as a viable alternative to glass fiber composites, particularly in automotive, packaging, building, and consumer product industries, and becoming one of the fastest growing additives for thermoplastics. Natural Fibers, Biopolymers, and Biocomposites provides a clear understanding of the present state

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Natural Fibers, Biopolymers, and Biocomposites by Amar K. Mohanty, Manjusri Misra, Lawrence T. Drzal in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Materials Science. We have over one million books available in our catalogue for you to explore.

Information

1

Natural Fibers, Biopolymers, and Biocomposites: An Introduction

Amar K.Mohanty, Manjusri Misra, Lawrence T.Drzal, Susan E.Selke, Bruce R.Harte, and Georg Hinrichsen

ABSTRACT Persistence of plastics in the environment, the shortage of landfill space, the depletion of petroleum resources, concerns over emissions during incineration, and entrapment by and ingestion of packaging plastics by fish, fowl and animals have spurred efforts to develop biodegradable/biobased plastics. This new generation of biobased polymeric products is based on renewable biobased plant and agricultural stock and form the basis for a portfolio of sustainable, eco-efficient products that can compete in markets currently dominated by products based on petroleum feedstock in applications such as packaging, automotives, building products, furniture and consumer goods. It is not necessary to produce 100% biobased materials as substitutes for petroleum-based materials immediately. A viable solution is to combine petroleum and bioresources to produce a useful product having the requisite cost-performance properties for realworld applications. Biopolymers or synthetic polymers reinforced with natural/biofiber frequently termed ‘biocomposites’ can be viable alternatives to glass fiber reinforced composites. The combination of biofibers like kenaf, industrial hemp, flax, jute, henequen, pineapple leaf fiber, sisal, wood and various grasses with polymer matrices from both non-renewable (petroleumbased) and renewable resources to produce composite materials that are competitive with synthetic composites such as glass-polypropylene, glassepoxies, etc., is gaining attention over the last decade. This chapter provides a general overview of biopolymers, natural biofibers, biocomposites and the research and applications of these materials. Biobased polymers such as polylactic acid (PLA), polyhydroxybutyrate (PHB), cellulose esters, soybased plastic, starch plastic, poly (trimethylene terephthalate), biobased resins from functionalized vegetable oils and biocomposites are also introduced in the chapter along with petroleum derived biodegradable polymers. Detailed discussions about the chemical nature, processing, testing and properties of these polymers, fibers and composites will be discussed in the remaining chapters of the book.

1.1 Introduction

As a result of a growing awareness of the interconnectivity of global environmental factors, principles of sustainability, industrial ecology, ecoefficiency, and green chemistry and engineering are being integrated into the development of the next generation of materials, products, and processes.1–7 The depletion of petroleum resources coupled with increasing environmental regulations are acting synergistically to provide the impetus for new materials and products that are compatible with the environment and independent of fossil fuels. Composite materials, especially “green composites,” fit well into this new paradigm shift. Simply stated, biobased materials include industrial products for durable goods applications, made from renewable agricultural and forestry feed stocks, including wood, agricultural waste, grasses and natural plant fibers composed of carbohydrates such as sugars and starch, lignin and cellulose, as well as vegetable oils and proteins. Producing chemical products and new materials from renewable resources is not a new idea. Most of the chemical products and materials came from renewable resources until the early part of the 20th century.1 The success and tremendous growth of the petrochemical industry in the 20th century, however, slowed the growth of biobased products. Environmental as well as economic factors are now driving the trend toward greater utilization of biobased polymers and materials.2–5 The challenge to scientists and engineers is to develop the technology needed to make the biobased materials revolution a reality.

The production of chemicals and materials from biobased feedstocks1 is expected to increase from today’s 5% level to ~12% in 2010, ~18% in 2020, and ~25% in 2030. Expectations are that two-thirds of the $1.5 trillion global chemical industry can eventually be based on renewable resources. The U.S. agricultural, forestry, life sciences, and chemical communities have developed a strategic vision6 for using crops, trees, and agricultural residues to manufacture industrial products, and have identified major barriers7 to its implementation. The Technology Road Map for Plant/Crop-based Renewable Resources 2020, developed by the U.S. Department of Agriculture (USDA) and the U.S. Department of Energy (DOE), has set a target of 10% of basic chemical building blocks arising from plant-derived renewables by 2020, with developed concepts in place by then to achieve a further increase to 50% by 2050.

Petroleum transitioned from a single product (kerosene in the early 1900s) to a multiproduct industry (fuel gas, gasoline, jet fuel, naphtha, diesel fuel, asphalt, chemicals, etc.) between the late 19th century and the middle of the 20th century. Research conducted from the 1990s to the present has led to many new biobased products.8–14 Some examples include polylactic acid (PLA) from corn; polyurethane products from soy oil; soy protein adhesives; solvents from soy and corn oil; lubricants from vegetable oil; thermoset and thermoplastic polymers from soy and corn; organic acids from crop sources; and biocomposites from lignocellulosic fibers combined with petroleumbased polymers like polypropylene (PP) and polyethylene (PE), or biopolymers like PLA, cellulose esters, polyhydroxyalkanoates, and vegetable oil-based bioresins. Recent advances in genetic engineering, natural fiber development, and composite science offer significant opportunities for new, improved materials from renewable resources, which can be biodegradable and recyclable but also obtained from sustainable sources at the same time.

The persistence of plastics in the environment, the shortage of landfill space, concerns over emissions during incineration, and entrapment and ingestion hazards from these materials have spurred efforts to develop biodegradable plastics. Several of the world’s largest chemical companies, including DuPont, Monsanto, Dow, and Cargill have announced a major shift in their base science and technology from traditional petrochemical processing to life sciences.15 DuPont and Monsanto have invested $12.5 billion to acquire expertise in agricultural biotechnology.16 Biopolymers are now starting to migrate into the mainstream and biobased polymers may soon be competing with commodity plastics. The best examples of biopolymers derived from renewable resources are cellulosic plastics like cellulose acetate, starch plastics like starch esters, and corn-derived plastics, i.e., PLA (polylactic acid). Sales growth rates of more than 20–30%/yr are expected along with improved economics as production and sales increase. The challenge in replacing conventional plastics with biodegradable materials is to design materials that exhibit structural and functional stability during storage and use, yet are susceptible to microbial and environmental degradation only upon disposal and without any significant environmental impacts.

1.2 Motivation: Biobased Materials vs. Environmental Impact

The successful transition to a biobased economy challenges the global academia, government, and industry. The world technology (WTEC) panel report17 has reviewed the status of “environmentally benign manufacturing” (EBM) technologies, applications, and policies in Europe and Japan in comparison to those in the United States. In this report, the main focus was given to polymers, electronics, transportation applications, and energy-related issues as well as the broader issues of government policies affecting environmental issues. The Biomass Research and Development Act of 2000 (U.S. Public Law 106–224), presidential executive orders 13134 (calling for tripling America’s use of biobased products by 2010) and 13101 (greening the government through recycling and waste prevention), and the Farm Security and Rural Investment Act of 2002 (Public Law 107–17), also known as the 2002 Farm Bill, together are creating an environment where there is an economic incentive to seriously consider biobased alternatives to petroleumbased materials. Biobased alternatives would play a role in reducing U.S. dependence on foreign oil. Biobased product development would have significant benefits for our citizens and society.

1.3 What Are Biocomposites?

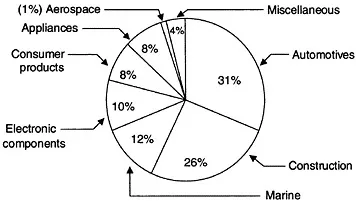

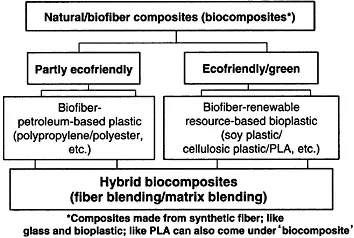

Composite materials are attractive because they combine material properties in ways not found in nature. Such materials often result in lightweight structures having high stiffness and tailored properties for specific applications, thereby saving weight and reducing energy needs. Fiber-reinforced plastic composites began with cellulose fiber in phenolics in 1908, later extending to urea and melamine, and reaching commodity status in the 1940s with glass fiber in unsaturated polyesters. From guitars, tennis racquets, and cars to microlight aircrafts, electronic components, and artificial joints, composites are finding use in diverse fields. The fiber-reinforced composites market (Figure 1.1) is a multibillion-dollar business.18 Glass fiber is the dominant fiber and is used in 95% of cases to reinforce thermoplastic and thermoset composites. Current research findings show that in certain composite applications, natural fibers demonstrate competitive performance to glass fibers. Broadly defined, biocomposites (Figure 1.2) are composite materials made from natural fiber and petroleum-derived nonbiodegradable polymers like PP, PE, and epoxies or biopolymers like PLA and PHAs. Composite materials derived from biopolymer and synthetic fibers such as glass and carbon also come under biocomposites. Biocomposites derived from plant-derived fiber (natural/biofiber) and crop/bioderived plastic (biopolymer/bioplastic) are likely more ecofriendly, and such biocomposites are sometimes termed “green composites.”

FIGURE 1.1 Fiber-reinforced plastic composites used in 2002—2.28×109 lb. (Adapted from Plast. News. August 26, 2002.)

FIGURE 1.2 Classification of biobased composites.

After decades of development ...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Preface

- About the Editors

- Contributors

- 1. Natural Fibers, Biopolymers, and Biocomposites: An Introduction

- 2. Plant Fibers As Reinforcement for Green Composites

- 3. Processing of Bast Fiber Plants for Industrial Application

- 4. Recent Developments In Retting and Measurement of Fiber Quality In Natural Fibers: Pro and Cons

- 5. Alternative Low-Cost Biomass for the Biocomposites Industry

- 6. Fiber-Matrix Adhesion In Natural Fiber Composites

- 7. Natural Fiber Composites In Automotive Applications

- 8. Natural Fiber Composites for Building Applications

- 9. Thermoset Biocomposites

- 10. Thermoplastic Wood Fiber Composites

- 11. Bamboo-Based Ecocomposites and Their Potential Applications

- 12. Oil Palm Fiber-Thermoplastic Composites

- 13. Natural Fiber-Rubber Composites and Their Applications

- 14. Straw-Based Biomass and Biocomposites

- 15. Sorona® Polymer: Present Status and Future Perspectives

- 16. Polylactic Acid Technology

- 17. Polylactide-Based Biocomposites

- 18. Bacterial Polyester-Based Biocomposites: A Review

- 19. Cellulose Fiber-Reinforced Cellulose Esters: Biocomposites for the Future

- 20. Starch Polymers: Chemistry, Engineering, and Novel Products

- 21. Lignin-Based Polymer Blends and Biocomposite Materials

- 22. Soy Protein-Based Plastics, Blends, and Composites

- 23. Synthesis, Properties, and Potential Applications of Novel Thermosetting Biopolymers from Soybean and Other Natural Oils

- 24. Houses Using Soy Oil and Natural Fibers Biocomposites

- 25. Biobased Polyurethanes and Their Composites: Present Status and Future Perspective

- 26. Cellulose-Based Nanocomposites

- 27. How Sustainable Are Biopolymers and Biobased Products? The Hope, the Doubts, and the Reality