Enabling Technologies for the Successful Deployment of Industry 4.0

- 131 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Enabling Technologies for the Successful Deployment of Industry 4.0

About This Book

This book offers the latest research advances in the field of Industry 4.0, focusing on enabling technologies for its deployment in a comprehensive way. This book offers successful implementation of technologies such as artificial intelligence, augmented and virtual reality, autonomous and collaborative robots, cloud computing, and up-to-date guidelines. It investigates how the technologies and principles surrounding Industry 4.0 (e.g., interoperability, decentralized decisions, information transparency, etc.) serve as support for organizational routines and workers (and vice versa). Included are applications of technologies for different sectors and environments as well as for the supply chain management. It also offers a domestic and international mix of case studies that spotlight successes and failures.

Features

-

- Provides a historical review of Industry 4.0 and its roots

-

- Discusses the applications of technologies in different sectors and environments (e.g., public vs. private)

-

- Presents key enabling technologies for successful implementation in any industrial and service environment

-

- Offers case studies of successes and failures to illustrate how to put theory into practice

-

- Investigates how technologies serve as support for organizational routines and workers

Frequently asked questions

Information

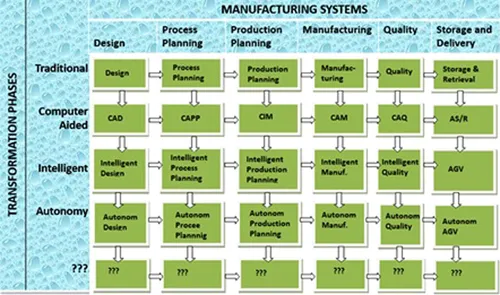

1 Understanding Digital Transformation

1.1 Introduction

1.2 Transformation and the Basic Challenges

1.2.1 Smart Factories

- Integration: Machines are not small equipment which can be changed easily. Keeping them running all the time without any problems is important. The digital designers should place a lot of effort in finding solutions to the problems without stopping the manufacturing lines.

- Connectivity: The machines in a smart factory are connected to each other and communicate one way or another. Sustaining this is important as the connection also serves as an information network carrying the information from one machine to others.

- Skills or behaviour: Machines are expected to perform the operator’s behaviour. There are two issues here. One is having the skills to generate the required intelligence to the machines, the other is to model the behaviour of the machine on human-like performance.

- Fragmentation: Generating a smart machine requires extensive knowledge. Turning this into a smart factory makes it even harder. Knowledge from various scientific disciplines is required. Fragmentation is important to simplify the selection and planning process. It gives a chance for people from different knowledge sets to work together.

- Security: It is important to keep the information network isolated to prevent machines from being accessed and hacked. This is also essential to keep machines running in harmony with others in the manufacturing suites. Security issues may also create a problem with customers if trust is lost. Digital designers should make an effort to sustain the required level of trust by running the system safely.

- Uncertainty: When generating smart factories, the highly complex nature of technologies makes it hard to assess potential benefits due to uncertainty about the particular adaptation of processes and respective smart capabilities. The cost of setting up a smart factory is too high and the possible benefits are uncertain until realized. The investors should be made aware of the fact that the transformation is inevitable and be given support during the transformation.

- Process management: Manufacturing companies will always face difficulties in changing traditional routines and processes to those running digitally. As there is no systematically proven approach for this, there will always be a tendency to keep traditional practices. This rigid culture is difficult to change. The designers should spend a great deal of effort to generate applicable business transformation models both to enable the transformation and to attract the people with the competencies to support it.

- Supply chain: The ability to simplify a complex supply chain requires time and innovative ideas in order not to lose a quick and fast response to the market. Since global operations expand due to the impact of digital transformation, the supply chain must also extend to a growing scope of geographical areas.

- Reduced lead-times: Today, the business world is experiencing very fast delivery of products and services. It is therefore very important to reduce lead-times. Tailored inventory programmes are essential. This may help reduce development cost and enables fast lead-times for customer-specific devices. Achieving this still requires research and a disruptive technology.

- Product lifetime: Ensuring long-term availability of technology helps keep products in production for as long as possible. This, naturally, maximizes the investment value. Efficient management of failures and predictive maintenance contribute to continuity of the production line. Receiving customer requirements and aligning the production line accordingly is another important aspect of sustaining product longevity. The designer should consider the functionality of the products as well as keep those in the market for longer times.

- Robustness and consolidation: This is as important as product longevity. Having high-quality and robust products, offering resistance to water, dust, impact, vibration and a range of other harsh conditions will be a key success to competition. This issue still remains open to new ideas.

- Demand management: Since smart factories allow fast response to customer requirements and customized products will seem to be available in the market, this may necessitate an active, efficient and effective demand management system. It would be wise enough to use this capability for marketing and the revenue generation process. In this respect the demand management system should have very specific capabilities which is yet to be developed.

1.2.2 Swarm Robotics

Table of contents

- Cover

- Half-Title

- Series

- Title

- Copyright

- Contents

- Preface

- Editors

- Contributors

- Chapter 1 Understanding Digital Transformation

- Chapter 2 Digitalization in Industry: IoT and Industry 4.0

- Chapter 3 Autonomous Robots and CoBots: Applications in Manufacturing

- Chapter 4 Augmented Reality and Virtual Reality: From the Industrial Field to Other Areas

- Chapter 5 Cloud Computing: Virtualization, Simulation and Cybersecurity – Cloud Manufacturing Issue

- Chapter 6 Industry 4.0 and Lean Supply Chain Management: Impact on Responsiveness

- Index