1

Introduction

It is hard to believe that the current approach to Japan’s quality improvement programme has changed the balance of the present trade situation between Japan and the rest of the world. It is evident that one of the most important aspects of Japanese quality improvement is the Japanese approach to quality management. Japanese companies have developed quality improvement (QI) in various stages, that is, from inspection after production to new product development through the stages of process control. The Japanese way of QI has been described by Ishikawa (1985), Sullivan (1986) and Yoshizawa (1987) who have pointed out the importance of the seven stages of QI. Even now, the value of effective QI has not been fully realized by many industries. In fact some people still think that it is the role of a quality department. They do not realize that QI is a way of life and the human aspect of it requires a great deal of education and training at all levels.

Improving quality is very often regarded as an activity which is going to increase cost. This view confuses the terms used in industry concerning quality and grade. Improving or raising the grade of products relates to the use of more expensive materials or processes to produce a product and will raise product costs. Improving quality means, among other things, making less faulty products with the same amount of effort or cost which usually gives a lower unit cost.

The cost of producing faulty products in the United Kingdom has been estimated as 10% of the gross national product: several thousand million pounds (Dale and Plunkett, 1991, p.). Improving quality aims to reduce this cost. This cannot be achieved overnight but requires an investment to be made in activities which are designed to avoid defective production, not activities designed to detect defects after they have been made.

The problem is knowing in what to invest (systems, technology, people) and it is this which seems to have bewildered Western industrialists. The search for the key to quality has been going on since the Japanese made us aware that we had missed something out along the way. Various analyses of Japanese success have attempted to condense the effect to one particular activity; hence fashions of ‘quality circles’ and ‘statistical process control’. The latest analysis has developed the concept of Total Quality Management’, which may well provide an answer to the problem. The keynote here is that the achievement of quality should not be considered to be a separate activity from the achievement of production.

Many large organizations are now trying to emulate that Japanese achievement in their commitment to quality. Each is developing its own approach and may give a different title to its efforts but each has similar elements to Total Quality Management’ (TQM). The development of Total Quality Management in America started at the beginning of the 1980s when American companies realized that not only Japan but also Korea and Taiwan were coming forward with quality products and services to capture the American market.

In Europe even now, with some exceptions, it is not unfair to say that European organizations lag behind those of Japan and the United States and it will be many years before they catch up with them. For the development of TQM European organizations looked for real explanations of the Japanese quality improvement in their quality culture and consensus management. Further, like the Japanese, European industrialists also tried to develop TQM from the teaching of American experts. In doing so, they realized that for the proper implementation of TQM they must understand the quality culture of their organizations and the country.

Kristensen, Dahlgaard and Kanji (1993) noted the importance of product quality to various business parameters. In order to assess the importance of competitive parameters for the company they investigated three different countries and the results are presented in Table 1.1 below. The respondents were allowed to choose between the following answers:

- irrelevant (1)

- unimportant (2)

- modestly important (3)

- rather important (4)

- very important (5)

It appears from the table that among manufacturing companies ‘product quality’ is considered to be the most important competitive parameter in all three countries. At the other end of the scale, we find that advertising is considered the least important parameter in all countries. However, between these two extremes we have found that the market price is ranked 5 in Taiwan and Korea and 4 in Japan. There is also reasonable consensus about the importance of assortment, which is ranked 8 in Taiwan and 7 in Japan and Korea.

Table 1.1 Evaluation of business parameters

Regarding delivery and warranty, opinions differ considerably among the three countries. For example, in Japan and Korea, delivery is considered very important with a rank of 2 and 3 respectively, whereas it plays a modest role in Taiwan. Since we were expecting delivery to be a very important parameter we were a bit surprised about the Taiwanese result. One explanation for this could be that the companies in Taiwan produce less goods to order than the companies in Japan and Korea.

The difference concerning the importance of warranty is much easier to explain. When the perception of quality is high, as is the case for Japanese products, warranty is not an important business parameter. On the other hand, when the quality level is unknown or is considered to be less than world class, as is the case for the newly industrialized countries of Taiwan and Korea, warranty becomes a very important selling point.

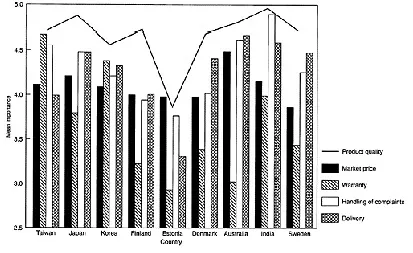

The authors’ recent QED studies (Dahlgaard, Kanji and Kristensen, 1992) regarding the importance of product quality to various business parameters for nine countries can be seen in Figure 1.1. The result indicates the differences between the various countries with respect to quality and four business parameters.

It is evident that in this competitive world, organizations and countries as a whole must achieve recognition from consumers about their top quality activities at all times in order to conduct business successfully. According to a worldwide Gallup poll of 20 000 people conducted recently by Bozell Worldwide of America (Figure 1.2), world consumers believe the best quality goods are made by Japan.

Fig. 1.1 Quality versus other business parameters. 1= irrevelant; 5 = very important.

Fig. 1.2 Quality league. (Source: Bozell Gallup poll.)

REFERENCES

Dahlgaard, J.J., Kanji, G.K. and Kristensen, K. (1992) Quality and economic development project. Total Quality Management, 3(1), 115–18.

Dale, B.G. and Plunkett, J.J. (1991) Quality Costing, Chapman & Hall, London.

Ishikawa, K. (1985) What is Total Quality Control?—The Japanese Way, Prentice Hall, Englewood Cliffs, USA.

Kristensen, K., Dahlgaard, J.J. and Kanji, G.K. (1993) Quality motivation in East Asian countries. Total Quality Management, 4(1), 79–89.

Sullivan, L.P. (1986) The seven stages in company-wide quality control. Quality Progress, 19, 77–83.

Yoshizawa, T. (1987) Exploratory Data Analysis in the Development Stage of New Products. Proceedings of the 46th session of the ISI invited papers, 5.3, 1–11.

2

Historical evolution of Total Quality Management

The historical evolution of Total Quality Management has taken place in four stages. They can be categorized as follows:

- quality inspection

- quality control

- quality assurance

- Total Quality Management.

Quality has been evident in human activities for as long as we can remember. However the first stage of this development can be seen in the 1910s when the Ford Motor Company’s ‘T’ Model car rolled off the production line. The company started to employ teams of inspectors to compare or test the product with the project standard. This was applied at all stages covering the production process and delivery, etc. The purpose of the inspection was that the poor quality product found by the inspectors would be separated from the acceptable quality product and then would be scrapped, reworked or sold as lower quality.

With further industrial advancement came the second stage of TQM development and quality was controlled through supervised skills, written specification, measurement and standardization. During the Second World War, manufacturing systems became complex and the quality began to be verified by inspections rather than the workers themselves. Statistical quality control by inspection—the post-production effort to separate the good product from the bad product—was then developed. The development of control charts and accepting sampling methods by Shewhart and Dodge-Roming during the period 1924–1931 helped this era to prosper further from the previous inspection era. At this stage Shewhart introduced the idea that quality control can help to distinguish and separate two types of process variation; firstly the variation resulting from random causes and secondly the variation resulting from assignable or special causes. He also suggested that a process can be made to function predictably by separating the variation due to special causes. Further, he designed a control chart for monitoring such process variation in order to decide when to interact with the process.

The main processes which help products and services to meet customers’ needs are inspection and quality control which require greater process control and lower evidence of non-conformance.

The third stage of this development, i.e. quality assurance contains all the previous stages in order to provide sufficient confidence that a product or service will satisfy customers’ needs. Other activities such as comprehensive quality manuals, use of cost of quality, development of process control and auditing of quality systems are also developed in order to progress from quality control to the quality assurance era of Total Quality Management. At this stage there was also an emphasis of change from detection activities towards prevention of bad quality.

The fourth level, i.e. Total Quality Management involves the understanding and implementation of quality management principles and concepts in every aspect of business activities. Total Quality Management demands that the principles of quality management must be applied at every level, every stage and in every department of the organization. The idea of Total Quality Management philosophy must also be enriched by the application of sophisticated quality management techniques. The process of quality management would also be beyond the inner organization in order to develop close collaboration with suppliers. Various characteristics of the different stages in the development of Total Quality Management can be seen in Table 2.1. Here QI, QC, QA and TQM are abbreviations of Quality Inspection, Quality Control, Quality Assurance and Total Quality Management.

The development of total quality management from 1950 onwards can be credited to the works of various American experts. Among them, Dr Edward Deming, Dr Joseph Juran and Philip Crosby have contributed significantly towards the continuous development of the subject.

According to Deming (1982), organization problems lie within the management process and statistical methods can be used to trace the source of the problem. In ...