eBook - ePub

Geometric Dimensioning and Tolerancing

Applications and Techniques for Use in Design: Manufacturing, and Inspection

James D. Meadows

This is a test

- 624 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Geometric Dimensioning and Tolerancing

Applications and Techniques for Use in Design: Manufacturing, and Inspection

James D. Meadows

Book details

Book preview

Table of contents

Citations

About This Book

Explaining the symbology of dimensioning and tolerancing and introducing a step-by-step system for geometric definition, this book provides examples for the application of geometric controls. The author breaks down the language of geometric product definition into a series of steps that consist of significant questions to be asked at any point in the product definition. He addresses functional requirements and manufacturing techniques, measurement, inspection, and gaging procedures. The book illustrates how symbology is best utilized, in what order it should be applied, and how each geometric control anticipates, integrates, and complements all other geometric controls on a part and in an assembly.

Frequently asked questions

How do I cancel my subscription?

Can/how do I download books?

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

What is the difference between the pricing plans?

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

What is Perlego?

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Do you support text-to-speech?

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Is Geometric Dimensioning and Tolerancing an online PDF/ePUB?

Yes, you can access Geometric Dimensioning and Tolerancing by James D. Meadows in PDF and/or ePUB format, as well as other popular books in Design & Industrial Design. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

GEOMETRIC DIMENSIONING AND

TOLERANCING

Section 1.1

An Explanation of Tolerance Zone Conversions

Geometric dimensioning and tolerancing is a system of symbols developed and used to define part shapes, feature form, orientation, runout, profile and location. Once tolerances are assigned, it should leave no doubt as to what is desirable and also acceptable to satisfy design intent. It is a system based on function and interrelationship of mating features while keeping in mind manufacturing and inspection capabilities.

Economy and repeatability are also key considerations given when applying geometric controls and will be further elaborated on throughout the body of this text. There are many advantages to the use of this system and most will become apparent as you become more accustomed to the language, principles and application of geometric dimensioning and tolerancing. To begin with, let us just state a couple of its most outstanding advantages.

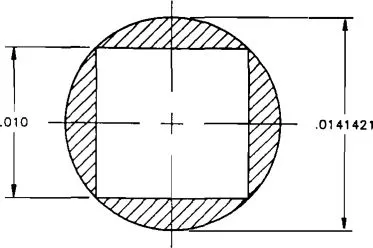

The use of cylindrical tolerance zones in locating cylindrical features is a real advantage. If circumscribed about an existing square (plus or minus) locational tolerance zone, it affords 57% more area of tolerance. This can usually be done without adversely affecting part function, provided mating features are dimensioned and toleranced to be compatible with the mating boundaries created. In addition, more tolerance is commonly made available through the use of the maximum material condition symbol or least material condition symbol. If the MMC concept is used, this additional geometric tolerance derived as the hole or shaft depart from maximum material condition size (smallest hole or largest shaft) is commonly referred to as a bonus. This bonus of tolerance is allowed without violating or changing existing mating part boundaries.

Again, if the MMC concept is used, this bonus of geometric tolerance beyond the geometric tolerance gained by changing to a circumscribed cylindrical tolerance zone is allowed only for features (using the MMC modifier symbol) as they depart from MMC while still fulfilling their size limit requirements. Additional tolerance within functional requirements means reduced part cost.

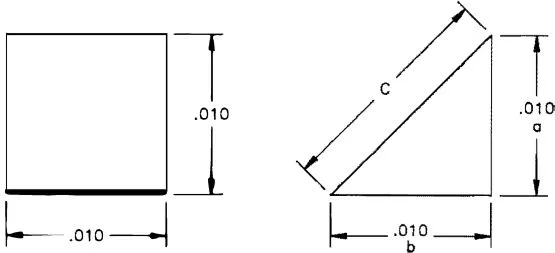

FIG. 1-1

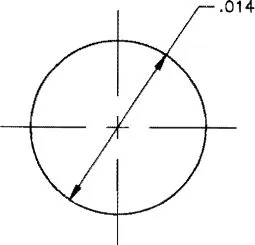

By means of the Pythagorean Theorem, we can find the length of the rectangular tolerance zone’s diagonal. The length of that diagonal will be the diameter of the equivalent cylindrical tolerance zone.

FIG. 1-2

FIG. 1-3

Some of the other advantages of this dimensioning and tolerancing system discussed in depth throughout the text are:

- (1) repeatability of part orientation through the use of datum features;

- (2) easy calculation of worst mating condition boundaries;

- (3) a use of geometric symbology for ease of part definition;

- (4) one standard used by all who create or interpret the drawing;

- (5) interchangeability of parts.

You will find as you become familiar with this system of geometric definition that functional relationships are not only dimensioned but toleranced with a simple arithmetic method to assure the most tolerance possible while maintaining part functionality. The result is that the parts work and cost is reduced.

Geometric dimensioning and tolerancing is a language of symbols based on good, sound logic. It allows a designer to express his or her thoughts and design requirements in a clear, concise manner. Tolerance zones, which in the past have not been allowed to be the same shape as the feature being protected and controlled, can now be defined as those shapes, for example, cylindrical tolerance zones for cylindrical features. This does not dictate that tolerance zones of other shapes stop being used, but does afford us the opportunity to more fully define our parts in more functionally precise ways never before available. It assures us that, if properly defined, parts made per design drawing requirements will also now fulfill design needs.

[Note: Inscribing the cylinder inside the square zone is also acceptable. If done on this part, the new tolerance zone would be a diameter of .010. Additional tolerance on the mating feature could then be experienced, by virtue of not increasing the tolerance zone to a diameter of .014 on this part feature.]

Section 1.2

Surfaces, Features, Features of Size, Datum Features, Datum Features of Size, and Datums

A part has surfaces. These surfaces either alone or at times in combination with one another can be cal...

Table of contents

- Cover Page

- Half title

- Title Page

- Copyright

- Preface

- Table of Contents

- Introduction

- Chapter #1 Geometric Dimensioning and Tolerancing

- Chapter #2 Maximum Material Condition, Least Material Condition, and Regardless of Feature Size

- Chapter #3 How to Read a Feature Control Frame

- Chapter #4 Size Controls Form

- Chapter #5 Rules, Concepts, Characteristics and Untoleranced Dimensions

- Chapter #6 Datums

- Chapter #7 The Maximum Material Condition Symbol and Its Ramifications

- Chapter #8 Relationships Between Individual Features

- Chapter #9 Virtual Condition and Resultant Condition Boundaries

- Chapter #10 Datum Feature or Size Representation

- Chapter #11 Form Controls

- Chapter #12 Orientation Controls

- Chapter #13 Profile

- Chapter #14 Runout

- Chapter #15 Location

- Chapter #16 A Logical Approach to Part Tolerancing

- Chapter #17 Dimensioning and Tolerancing Schemes

- Chapter #18 Steps for the Development of a Dimensional Inspection Plan

- Chapter #19 Paper Gaging

- Chapter #20 Functional Gaging

- Definitions

- Bibliography

- Index

Citation styles for Geometric Dimensioning and Tolerancing

APA 6 Citation

Meadows, J. (2017). Geometric Dimensioning and Tolerancing (1st ed.). CRC Press. Retrieved from https://www.perlego.com/book/1610760/geometric-dimensioning-and-tolerancing-applications-and-techniques-for-use-in-design-manufacturing-and-inspection-pdf (Original work published 2017)

Chicago Citation

Meadows, James. (2017) 2017. Geometric Dimensioning and Tolerancing. 1st ed. CRC Press. https://www.perlego.com/book/1610760/geometric-dimensioning-and-tolerancing-applications-and-techniques-for-use-in-design-manufacturing-and-inspection-pdf.

Harvard Citation

Meadows, J. (2017) Geometric Dimensioning and Tolerancing. 1st edn. CRC Press. Available at: https://www.perlego.com/book/1610760/geometric-dimensioning-and-tolerancing-applications-and-techniques-for-use-in-design-manufacturing-and-inspection-pdf (Accessed: 14 October 2022).

MLA 7 Citation

Meadows, James. Geometric Dimensioning and Tolerancing. 1st ed. CRC Press, 2017. Web. 14 Oct. 2022.