- 240 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Wouldn't it be great if you could design a product with the customer in mind - right from the very start? Well, now there's a way: Quality Function Development, or QFD, translates the needs of the consumer directly into the design and development of new products and services. By focusing on customer needs and incorporating them into every phase of the manufacturing process, it eliminates waste and improves customer satisfaction. And that means increased sales, greater profits, and a bigger share of the market.Step-by-Step QFD is a practical, hands-on guide to implementing QFD at any organization. Written by an expert in the field, it shoes how the intensive study of consumer needs can be used to help you dramatically outperform the competition. In fact, the strategies outlined in this book have already met with great success at a number of corporations both within and outside of the United States. This workbook includes a case study of QFD in action, 34 helpful workshops, and an analysis of the synergy between QFD, TRIZ, and Taguchi. So whether you're a QFD trainer, project manager, design engineer, or manufacturer, Step-by-Step QFD will show you how to let one voice drive your entire design process - the customer's!

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Introduction

Upon completing this chapter, you will be familiar with:

♦ The essence of QFD.

♦ The evolution of QFD.

♦ The benefits of using QFD.

♦ Case studies of successful applications of QFD.

♦ Guidelines for adapting QFD to your organization.

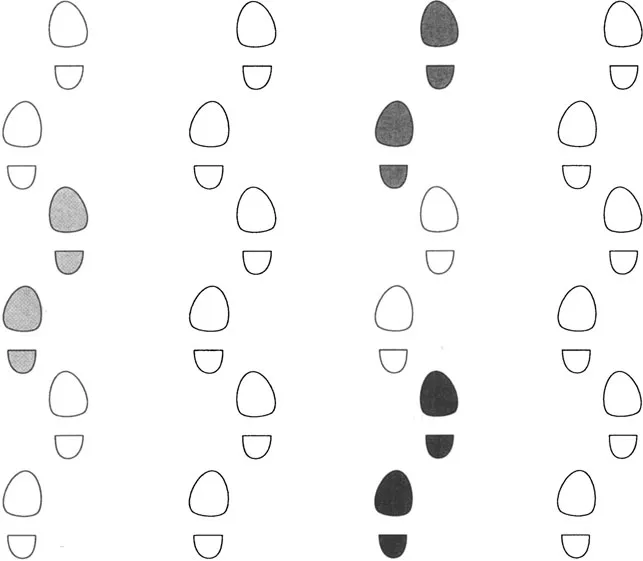

Figure 1-1

Introduction

This manual will be your guide for the journey through the design process, beginning with the murmurs of your customer and ending with increased market share. The book is primarily intended for three types of readers: people who are studying Quality Function Deployment (QFD) for the first time, practitioners in their first year of using QFD and organizations that are experiencing manufacturing difficulties. While the manual includes information for model upgrades, it focuses on new product design.

Included in this manual are a number of features that enable readers to learn about QFD on their own, independent of a QFD course or seminar. The workshops, appendix and glossary function as guides, helping QFD students complete their journey toward a world-class product. Many journeys in our lives include resting places where we can stop while climbing a mountain and reap the benefits of the sights without going all the way to the highest peak. Similarly, Step-by-Step QFD points out intermediate destinations where the QFD practitioner may choose to pause and implement one aspect of QFD. Some readers may choose to terminate the QFD process after using only one tool; others may decide to complete the book and embark upon a more comprehensive QFD application.

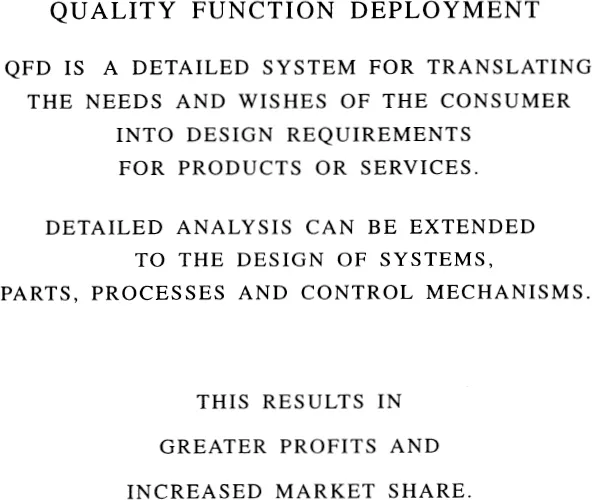

Before starting the journey, it is helpful to define QFD and to examine recent QFD projects. QFD is a modern quality system aimed at increasing market share by satisfying the customer. This system strategically selects and makes visible customer requirements that are important for outperforming the competition.

Once customer needs are understood, they are translated into design requirements. The subjective desires of the customer are mapped into the language of the engineer. QFD focuses on delivering value by understanding the customer’s wants and needs and then deploying these expectations throughout the development process. This includes identifying the best values for components, parts or materials. To manufacture a world-class product, the customer information must be deployed to the manufacturing process and control systems. A complete design process would include packaging, delivery and support. The end results are increased market share and greater profits.

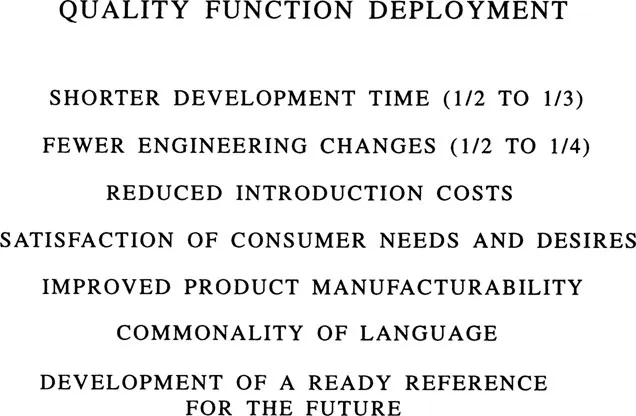

These benefits are the result of reduced development time by a factor of 2 or 3. Reducing the number of engineering changes can significantly increase profits. Companies frequently set aside large sums of money as contingency for introduction problems. With QFD, introduction costs decrease and market share grows because of satisfied customers who have a product that meets or exceeds their needs and desires. Besides reducing production costs, QFD facilitates communication and cooperation among various functions of an organization.

Figure 1-2

Figure 1-3

Another substantial benefit of the QFD process is the development of a common language. Discussions during the entire design process identify miscommunications resulting from contrasting value systems or different vocabularies. An active glossary of terms is developed and linked to each analysis activity. Teams also produce matrices and tables that provide further documentation of their activities. These documents become increasingly comprehensive, providing a ready reference for related products and future model upgrades. With its creation of a common language and thorough documentation, QFD develops an organization’s sensitivity to the customer’s demands. QFD designs value into your product. Only a focused effort can make a product so good that customers boast about it—the true test of the delighted customer.

QFD builds quality into products by fostering a coherent design process. Consumers generally make subjective statements when evaluating a product. QFD employs a variety of strategies to systematically translate this feedback into objective design requirements. These design requirements are communicated to all relevant organizational functions so that everyone is working toward a synergistic whole.

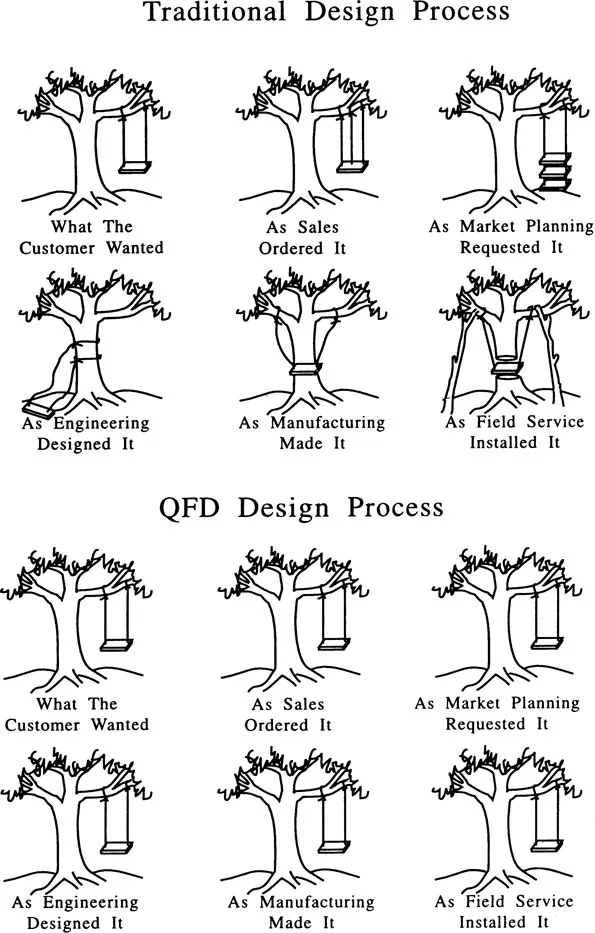

As seen in an old Readers Digest cartoon (Figure 1-3), the customer, a child, wants a simple rope swing. The sales person decides to enhance the design with three ropes. Marketing envisions three happy children in its sales campaign. The engineering staff has become sensitive to injured party lawsuits and does not want anyone to fall. The manufacturing team believes it knows what the customer really wants. Finally, because of a lack of training, the field person does not know how to install the swing. In this hypothetical example, every organizational function has its own version of what the customer desires. Each version reflects a different group’s unique view of the world. The QFD process aligns the entire organization.

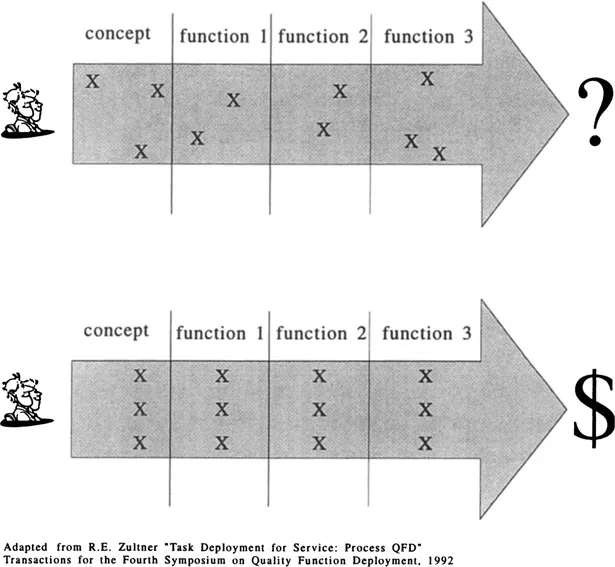

Few experiences are more discouraging than doing your best, only to discover over the course of a project that your labors will not make a difference. Figure 1-4 further illustrates the incoherent process that frustrates talented employees. The upper figure shows a concept team that is proud of three aspects of its design, as indicated by the X’s. The team passes these concepts on to functional unit 1, possibly the development team. This second group values a different set of strengths, but the two that they are most proud of do not align with the concept team’s three contributions. This misalignment of effort can continue throughout the development process. If none of the X’s are in line with the most important customer need, this need becomes lost in the design process. This approach results in a game of chance, indicated by the large question mark.

The bottom portion of Figure 1-4 illustrates how QFD aligns the entire organization with the customer’s perspective. By concentrating everyone’s efforts on the customer’s needs, QFD involves all of the organization’s functions in the design process. This focus promotes a coherent process where practitioners can focus on what they do best and know that their efforts count.

Figure 1-4

The Role of the Customer in Design

Traditional marketing techniques simply do not provide the level of detail utilized by the normal QFD process. QFD tools examine the customer needs in detail from a variety of angles. Some marketing organizations have built their reputations upon these precise methods. At the 1990 Novi Symposium, Robert Klein of Applied Marketing Science, Inc. presented the integration of several marketing improvements into a process he called VOCALYST™. The study originated from John R. Hauser’s research at MIT’s Sloan School of Management using a four-phase process: interviews with customers, transcription of the tape-recorded interviews, data grouped in a variation of the affinity diagram and cluster analysis to calculate the importance of customer needs.

With its intensive study of customer needs, QFD has generated innovative strategies for outperforming the competition. For instance, the Kano Model reveals that zero defects for basic needs does not mean a satisfied customer. Does the product do what is desired in a way that is exciting? The features which result in increased satisfaction with improvements in performance are the common indicators for a happy customer. The uncommon feature will catch the competition off stride. An organization must identify some excitement features for its product. Some features are not expected. Just a hint of the feature excites and makes the customer happy. In high tech industries, today’s exciting features are tomorrow’s expected features. In order to ensure the production of quality products, organizations must keep in touch with their customers so that they know how and when their needs are changing. Chapter 4 addresses the Kano Model in greater detail.

A playful definition of quality underscores the importance of this intimacy between an organization and its customers:

“Quality is what makes it possible for a customer to have a love affair with your product or service. Telling lies, decreasing the price or adding features can create a temporary infatuation. It takes quality to sustain a love affair.

Love is always fickle. Therefore, it is necessary to remain close to the person whose loyalty you wish to retain. You must be ever on the alert to understand what pleases the customer, for only customers define what constitutes quality. The wooing of the customer is never done.”(Myron Tribus in ASQC Statistics Division Newsletter, 1990)

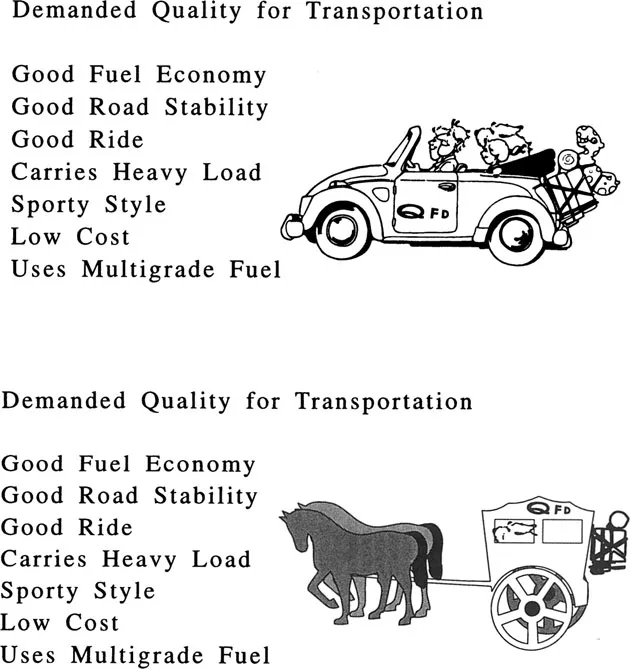

To really understand and “woo” its customers, an organization must go to their environment and actually observe the customers using the product. The Japanese call this form of market research “going to the Gemba.” This journey leads to a better understanding of the product’s context of application, a vital component of product design. Figure 1-5 provides a concrete example of how this context of application shapes designs. In this example, an organization designs privately owned transportation vehicles. One customer states seven requirements, starting with “good fuel economy.” The old-style VW was an exciting solution in the 1950s–1970s, but this is no longer the case. Another customer states the same requirements, but the most appropriate design looks nothing like the first design.

The second customer lives in a location without paved roads or gasoline stations. There are heavy rains and no bridges. Going to the Gemba and viewing the context that shapes customer requirements is an essential step for creating appropriate designs.

The following case studies of American applications of QFD demonstrate the value of going to the Gemba, thus affirming Tribus’s assertion that “The wooing of the customer is never done.”

Figure 1-5

Going to the Gemba and a Successful QFD Project

When looking at organizations using QFD, it is important to consider the breadth and depth of their applications. A company using an application that has depth will employ QFD activities for a variety of different processes; these might include customer research, design activities and the manufacturing processes. A QFD project that has depth contains a variety of analyses. The breadth of application is a measure of QFD’s persuasiveness throughout an organization. QFD consultant Richard Zultner coined these phrases. The following three case studies illustrate QFD applications, each one involving...

Table of contents

- Cover

- Title Page

- Copyright Page

- Table of Contents

- Foreword

- Preface

- Acknowledgments

- Chapter 1 Introduction

- Chapter 2 Flow of Analysis in Step-by-Step QFD

- Chapter 3 Priority of Customer Segments

- Chapter 4 Understanding Your Customer

- Chapter 5 Customer Voice into Design Team Voice

- Chapter 6 A Better Way to Measure Quality

- Chapter 7 New Design Concepts

- Chapter 8 Theory of Inventive Problem Solving

- Chapter 9 Voice of Customer to Manufacturing

- Chapter 10 Robust Design in Manufacturing

- Chapter 11 Admonitions

- Appendix

- Glossary

- Bibliography

- Index

- Worksheets

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Step-by-Step QFD by John Terninko in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.