- 186 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Supply Chain Management Workbook

About this book

'Supply Chain Management Workbook' provides an overview of the supply chain process and addresses the key aspects involved in a supply chain.

A checklist is included to enable an assessment of a company's procedures and the facilities it offers. By working through this list of questions the weaknesses in the management of the supply chain can be identified and subsequently addressed.

The combination of theoretical underpinning along with a means of self evaluation results in a practical guide which will be invaluable for companies wishing to improve their supply chain management.

Published in Association with The Institute of Operations Management, http://www.iomnet.org.uk.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

The end customer

The end or final customer is the person at the end of the supply chain who makes the decision whether or not to buy the product or service offered. The purchasing decisions of the end customer have some proportional effect on each facet of the supply chain contribution to the finished product.

It is the end customer that brings profit to the supply chain. Profits for the supply chain are dependent on the customer’s purchasing decisions and on the efficiency of the supply chain to produce the product. Each process, either internally or externally, should be adding value to the product. Processes that do not add value diminish the levels of profit that can be achieved. The levels of profits that can be achieved and the continuation of these relationships form the basis for managing and integrating the supply chain.

Perceptions generally about who the end customer is may vary along the supply chain. Take a manufacturer for example, employing hundreds of people. From the supply-base perspective the manufacturer for day-to-day transactions may well be regarded as the end customer. Given that this perspective prevails, the manufacturer is perceived as the ‘responsible’ entity for communicating demand – where satisfaction begins and ends.

The perception that satisfying the demands of the next customer is the end of the supply obligation is important. In the above example the manufacturer might supply an original end manufacture (OEM). The OEM in turn might integrate the supplied product into its own product for supply to a distributor. The distributor then adds value to the product by marketing it to attract the end customer. One begins to understand that any one link, whatever its scale, must ‘accept’ responsibility for improving the information flows and understanding of the needs of the other.

The inward perception fails to realize the importance of the customer–supplier relationships throughout the total supply chain. Moving attitudes away from ownership detachment to an outward view that realizes the importance of the end customer in all aspects of the supply chain will help to make the supply chain more efficient and responsive to the needs of the customer.

Understanding the customer

To understand the customer there must, first, be some direct link with the customer and, second, it is essential that these information channels ‘speak the language’ of the customer. Learning what frustrates or delights the customer can be done on a one-to-one basis or in groups, with surveys and interviews. Information about customers’ preferences, buying habits, attitudes toward particular products and service satisfactions can be collated to form ‘scientific’ customer profiles, which are not based on assumptions and perceptions.

Getting closer to the customer, compiling information about the customer’s first enquiry, repeat ordering patterns, service satisfaction and customer attitudes will provide the inputs for designing the product and value package that matters to the customer. Knowing what matters to the customer will help align the supply chain towards meeting and exceeding customer expectations.

In markets where demand exceeds supply (seller’s market), it may be ‘acceptable’ to align business attitudes along the lines of ‘make a product then sell it’. In a seller’s market, competing for the end customer may focus the organization’s resources on internal excellence, i.e. the product, reliability, quality, price and relative lead time.

In today’s marketplace, global competition has increased capacity to produce products. The result is excesses in supply and equality of physical products. This increased capacity, coupled with a more discerning customer, means that producers must focus on excellent internal and external performance.

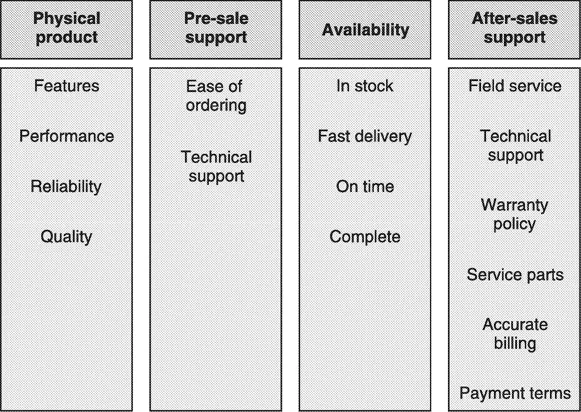

Figure 1.1 lists some differentiating attributes. The left-hand column contains the product (internal) related issues. The other three columns list a variety of issues that are not product related – these are external performance related. The internal and external benefits which can be provided are part of the competitive need to develop the supply chain in order to realize the maximum benefits that will form the total value package.

Figure 1.1 Differentiation attributes

Source: Mather (1998).

Retaining the customer

It takes five times as much effort, time and money to attract a new customer than it does to keep an existing customer (Christopher, 1994). One study of the car market in the USA found that a satisfied customer stays with the same supplier for a further twelve years after the first satisfactory purchase and during that period buys four more cars. To the car manufacturer this level of customer retention is estimated to be worth $400 million per annum in new car sales.

Research (Christopher, 1994) has shown that retained customers are more profitable than new customers, for the following reasons:

1 The cost of acquiring new customers can be substantial. A higher retention rate implies that fewer customers need be acquired and these can be acquired more cheaply.

2 Established customers tend to buy more.

3 Regular customers place frequent, consistent orders and therefore usually cost less to serve.

4 Satisfied customers often refer new customers to the supplier at virtually no cost.

5 Satisfied customers are often willing to pay premium prices for a supplier they know and trust.

6 Retaining customers makes market entry or share gain difficult for competitors.

The customer’s purchasing decision will take into account the total value package on offer, i.e. the total or differentiating attributes compared with a competitor’s similar product. As part of the decision to make the purchase the customer will have some basic expectations. For example, the product must be ‘fit for purpose’. Adding to the value package something so new or a feature that was not anticipated by the customer will exceed the customer’s expectations and he or she will be delighted with the purchase.

Satisfying the end demands of the supply chain whatever the product or service offered is not only a moving target, but increasingly today’s basic needs were yesterday’s unexpected delights. It is an important fact that the features that delight the customer today will gradually move towards spoken needs, and eventually become basic expectations:

1 Basic spoken needs: these are the needs the customer regards as so elemental they do not need mentioning. If these needs are not met the customer will be dissatisfied.

2 Spoken needs: these needs might be requested features that the customer would like as part of the total value package. They are options that will satisfy the customer.

3 Unspoken needs: these are unexpected delights. The customer had not anticipated this attribute as part of the value package.

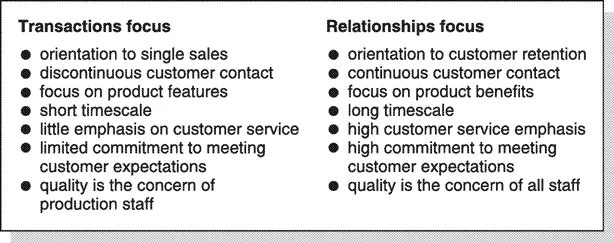

Retention of customers is the focus for ‘relationship’ marketing (Christopher, 1991). Customer retention has many benefits, including development and alignment of the total value package. The principle of relationship marketing is that the total package offered to the customer comprises a core product and a service package that surrounds it. The idea is to create such a level of customer satisfaction that the customer is unlikely to look for an alternative supplier. The shift to relationship marketing is shown in Figure 1.2.

Figure 1.2 The shift to relationship marketing

Source: Christopher (1991).

The internal customer

The internal customer is an internal delivery partner, processing parts for the next operation. Treating internal customers as delivery partners is a recognition that we must understand their needs and expectations. The partnership approach shifts the focus for daily activities from an inward perspective to an outward perspective, raising individual and collective responsibility for eliminating wasteful practices at every opportunity, and in doing so delivering the right parts at the right time to the right place to the right quality to the next operation.

The delivery partnership is a culture of listening and improving. Employees are encouraged to raise ideas and suggestions, and take responsibility for their work and their development. The company should provide education and training programmes that help employees identify with the goals and objectives of the company. Employee integration requires communication and recognition. This is emphasized by the company setting common measurements which make progress and improvements visible for all to see. Objectives are shared and achievable, and work activities are planned and measured.

The supply partners

The external supply base is an integral part of the supply chain game plan. Often, however, suppliers are treated as a distinct entity and kept at arm’s length, the driver for communication being supply disruptions and reactive cost reductions to marketplace conditions.

Typically a medium to large-sized company spends in excess of 50 per cent of sales revenue on purchased items. The integral clarity of procurements ability to source from the best suppliers, and the best suppliers’ ability to meet the demands of the customer has been obscured by the traditional confrontational approach, encompassing:

• distrust of suppliers

• competitive tendering

• a lack of knowledge about what components or services should cost

• a lack of real ability to focus on management of suppliers

• narrowly focused objectives

• lack of awareness of causes of waste

• short-term business horizons

• ‘macho’ business mind-set.

The Japanese have led the way in realizing the importance of customer–supplier relationships. They have developed collaborative arrangements for all aspects of mutual involvement. This has enhanced the range of services that the supplier is able to offer. The supplier becomes an integral part of the supply chain strategy, taking responsibility for product design and development, warehousing and inventory management, cost-reduction initiatives and customer–supplier cross-functional skills sharing.

The form of partnership may vary. For example, it may comprise some degree of financial integration through minority equity or out-right purchase, or preference will form the basis of a partnership. Whatever form of partnership is deemed appropriate, fundamentally it should be based on long-lasting and mutually beneficial understanding, together achieving business growth and success at the expense of the competition. In this respect they will work together to eliminate waste in all aspects of their transactions. They will work together in cost transparency mode. Each partner knowing about the other will produce understanding of the elements of product cost, quality and any consequential problems that may arise.

Chapter 2

Manufacturing in essence

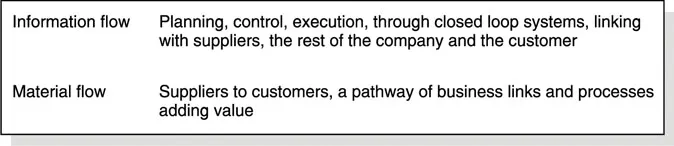

Essentially manufacturing and, indeed, the supply chain are a flow of information and materials, illustrated in Figure 2.1. In essence the objective of manufacturing is to improve and speed up the flow of information and smooth the flow of materials.

Figure 2.1 Flows of information and material

The speed of information flow can literally be at the speed of light. For example, computers, fax machines and telephones can connect information exchange ‘immediately’. Where information flow is a people-managed activity the rate of flow is slowed. The rate and management of information flow becomes dependent on people intervention and individual responsibility, and may depend on a number of variables affecting its management, such as workloads, attitudes, and so on. Effective information flow is a prerequisite to effective material flow, and both need to be accurate, swift and balanced.

Effective information flow must be freely directional, travelling to where it is required and received back to wherever it is required. Messages and feedback need visible pathways so that any information flow breakages can be identified.

Material flow and flexibility are a synonym...

Table of contents

- Cover

- Halftitle

- Title

- Copyright

- Contents

- Introduction

- Abbreviations

- 1. The end customer

- 2. Manufacturing in essence

- 3. Changing market forums: The Internet

- 4. The product

- 5. Mass customization

- 6. What is forecasting?

- 7. Customer order management

- 8. What is demand management?

- 9. The master production scedule

- 10. Shop-floor control

- 11. Purchasing

- 12. Supplier partnering

- 13. Logistics

- 14. Distribution resource planning

- 15. Supply chain management checklists

- 16. Checklist: Chapter 1

- 17. Checklist: Chapter 2

- 18. Checklist: Chapter 3

- 19. Checklist: Chapter 4

- 20. Checklist: Chapter 5

- 21. Checklist: Chapter 6

- 22. Checklist: Chapter 7

- 23. Checklist: Chapter 8

- 24. Checklist: Chapter 9

- 25. Checklist: Chapter 10

- 26. Checklist: Chapter 11

- 27. Checklist: Chapter 12

- 28. Checklist: Chapter 13

- 29. Checklist: Chapter 14

- Bibliography

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Supply Chain Management Workbook by Francis Harrison in PDF and/or ePUB format, as well as other popular books in Business & Business General. We have over one million books available in our catalogue for you to explore.