![]()

1

Practical skills

This book, while applicable to several types of pneumatics course, is targeted in particular at the City & Guilds 2340 scheme in Fluid Power Engineering Part 2 (Pneumatics). Basic practical skills are generally acquired in the working environment, but this programme of study recognizes the need for further training in the understanding and application of pneumatic technology, together with regard to safety, project planning and systematic maintenance and fault-finding.

Underpinning knowledge is included here only in so far as it is necessary to support the practical skills; however, to support the level of skill which is expected and necessary in today’s workplace, a considerable theoretical syllabus, reproduced in Appendix A, has resulted.

1.1 Aims of the City & Guilds 2340 Scheme in Fluid Power Engineering

The basis, aims and products of the City & Guilds programme are comprehensively covered by the Scheme pamphlet, together with Tutors/Trainers - Notes for Guidance, obtainable from City & Guilds, London. To quote briefly and selectively from the scheme pamphlet:

Aims of certification

Candidates who achieve the certificate(s) in Fluid Power Engineering Competences will have demonstrated that they have acquired

(a) an ability to perform competently practical tasks relevant to the installation, commissioning, maintenance and fault-diagnosis of pneumatic systems.

(b) a generalised practical mastery of the technology used in their practical tasks so that they may progress to other applications in new tasks or new training without relearning the main skill content of the process.

(c) the necessary competences in practical communication, task planning, doing and checking the results of work.

(d) a basis for informed assessment of their personal aptitudes and attitudes in relation to their work.

(e) confidence in a new role.

Practical tasks and assessment - aims

The aim of assessment is to provide evidence that candidates have acquired practical competence. The criterion of success is the demonstration of the ability to do the job and mastery criteria are used to determine how well candidates perform. These criteria must be met for candidates to be considered competent.

The programme is structured so that the existing skills of a candidate, based on evidence provided, are recognized as elements contributing to a final certificate. Quoting again from the scheme pamphlet:

It is stressed that certificates are awarded for the acquisition of competences whether in an integrated course or by credit accumulation and not for serving a period of study. It is for this reason that no reference is made in the scheme to fixed periods of study time or how long a course should be: this will depend on the background and abilities of trainees undertaking the course.

1.2 Ability criteria

The ability criteria have been devised as a framework for the teaching and assessment of skill and split into the following four categories:

1.1 Interpret pneumatic circuit diagrams

1.2 Construct pneumatic systems from given information

1.3 Identify and rectify faults in pneumatic systems

1.4 Carry out routine maintenance on pneumatic systems.

Each category is broken down further into the elements of competence:

1.1 1.1.1 Components correctly identified.

1.1.2 Application of components identified.

1.1.3 Operation of pneumatic system relating to control inputs and machine outputs identified.

1.2 1.2.1 Appropriate components selected and adjusted as necessary

1.2.2 System assembled in a safe and efficient manner.

1.2.3 Start-up and commissioning procedures correctly specified and followed.

1.2.4 System operates according to requirements.

1.2.5 Safe working practice and statutory regulations followed at all times.

1.3 1.3.1 Nature of faults correctly identified.

1.3.2 Fault-finding checklist prepared.

1.3.3 Diagnostics used to locate fault, ensuring safety at all stages.

1.3.4 Machine/system shut down safely in correct sequence as necessary.

1.3.5 Faulty component repaired/ replaced/adjusted as necessary.

1.3.6 Cause and effect of faults correctly assessed.

1.3.7 Machine/system recommissioned in accordance with set procedures.

1.3.8 Machine/system operates according to requirements.

1.3.9 Safe working practices and statutory regulations followed at all times.

1.4 1.4.1 Service/maintenance require established schedule.

1.4.2 Servicing/maintenance undertaken, as per schedule, in safe and efficient manner.

1.4.3 Performance testing of components carried out, as necessary.

1.4.4 System tested after maintenance to ensure efficient working.

1.4.5 Safe working practice and statutory regulations followed at all times.

1.3 Elements of competence

Candidates may be understandably put off by the dry descriptions of skills required, so here is a summary which may help:

1.1 Interpret pneumatic circuit diagrams

— You must recognize components and know how to apply them.

— You must understand how a circuit is controlled and how it carries out its working functions.

1.2 Construct pneumatic systems from given information

— You must be able to select and correctly adjust components to perform the working functions of a system, assemble them safely and efficiently, and commission the system using safe procedures. The system must work as specified and you must follow safe practices and be aware of and observe the applicable safety regulations.

1.3 Identify and rectify faults in pneumatic systems

— You must identify the faults in a system correctly, prepare a checklist to provide a systematic fault-finding procedure and locate the faults with diagnostic testing with regard to safety throughout. A safe shutdown sequence must be used. The circuit or component faults must be repaired or corrected by adjustment or replacement and the cause and effect of faults identified. The machine must be started up using a safe procedure, operate as specified, and you must follow safe practices and be aware of and observe the applicable safety regulations.

1.4 Carry out routine maintenance on pneumatic systems

— An established schedule must be used for all servicing/maintenance, which must be carried out as scheduled, safely and efficiently. Components and systems should be performance tested after maintenance. You must follow safe practices and be aware of and observe the applicable safety regulations.

In the training environment, practical assessment tasks may be small-scale systems created on a ‘pegboard’ or in a training unit providing a selection of small components. Safety is a recurrent feature of the assessment criteria to reflect the considerable danger associated with pneumatics in factory applications. Training rigs seldom duplicate these dangers, so normally they must be imagined, and all procedures carried out and documented as if the system is large, powerful and dangerous.

![]()

2

Units and calculations

2.1 Units of measurement

The SI metric

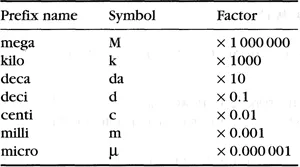

base units have a consistent logical basis: all measurements are made in the terms of a basic unit applicable to the property. If this results in awkward figures, then prefixes can be applied which multiply or divide the basic unit by 10 or factors of 10 as required. Grams, for example, which are a small unit of mass or weight, are more often encountered in ordinary life as kilograms, i.e. units of 1000 grams, but for tiny measurements they are also encountered as milligrams, i.e. units of

of a gram.

The prefixes are similar for all the basic units. The more common ones are given in Table 2.1.

Table 2.1 Common unit prefixes

The basic units used in pneumatics are as shown in Table 2.2 - imperial equivalents (in brackets) are for comparison only.

Other practical pneumatics units are derived units or combinations of basic units, some with spe...