- 440 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Food Processing: Principles and Applications is a comprehensive resource that explores the basic and applied aspects of food processing. It describes the physical, chemical, and microbiological basis for each method of preservation. Particular emphasis is placed on the application of three of the most universally used commercial processes: t

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Introduction

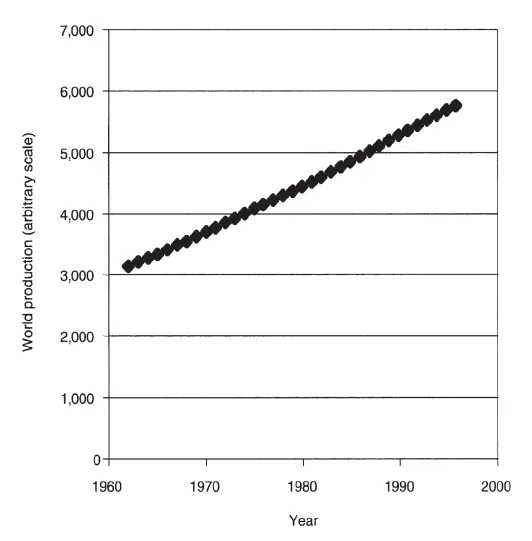

It is generally accepted that world food production is not increasing at the same rate as population growth. Population control activists routinely argue that the world cannot continue to support an ever-increasing population. In 1798, Thomas Malthus wrote one of the most widely cited articles advocating population control “An Essay on the Principle of Population.” He recognized that population growth is dependent on the current population; hence, the more the population at any given time, the more the population growth will be. This idea led to the concept of “exponential growth” for the population. The population would increase by 50% every 20 years. This would mean more than doubling the population every 40 years. Figure 1.1 shows a population chart compiled by the United Nations’ Food and Agricultural Organization (FAO), which, in fact, shows much more than a linear increase in population with time.

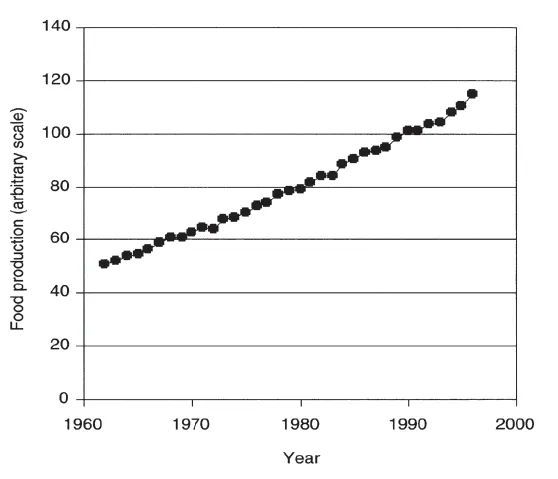

On the other hand, food production is limited by available land, water for irrigation, and so on. These things are finite. At best, food production might increase by the same amount every year, which means the food production would normally increase at a linear or nearly linear rate. But even that linear rate of growth might eventually be impossible to maintain, as available land, water, and other resources are used up, and increases in food production would start to taper off. Thus, with the population expanding at a faster rate than food production, sooner or later it will be impossible to feed all the people, and there will eventually be mass starvation. However, contrary to expectations, food production has kept a good pace with population during the past 50 years (Figure 1.2).

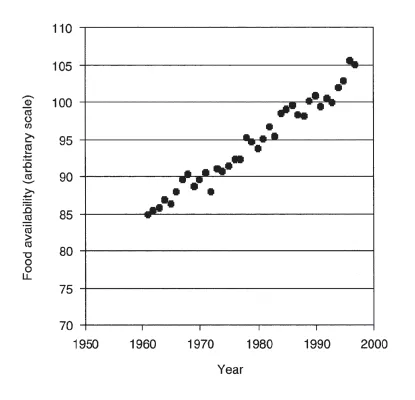

There have been several theories that speculate how it has been possible to continue to increase production year after year for the past several decades. One theory is that the major limitation for food production, decades back, was the number of farmers available to work the land. This is perhaps true even today in developing countries where the agricultural land is mostly owned in small lots by multitudes of individual farmers. As the population started growing, more farmers were available for agricultural production. Perhaps the most significant contributing factor to agricultural production is the “Green Revolution” involving improved irrigation, selective breeding of improved crops, and high potency fertilizers. The agricultural production was continually maximized by employing modernized agricultural operations, intensified planting, high-yielding varieties, effective use of fertilizers, growth promoters, etc. These aspects were the focus of attention, especially in the 1960s and 1970s, particularly in developed countries. These practices have found only limited scope in developing or underdeveloped countries, where agricultural practices are mostly limited to multitudes of tiny farming sectors. Some also argue that these advances have now reached their limits and that all that has been accomplished is merely postponing the disaster—and that we are now once again pushing the limits. Although it might be pessimistic to assume that after decades of advances, agricultural technology is now going to stop dead or lack innovation, the limitations surely need to be recognized. Adapting more land for cultivation could be an attractive alternative. Some argue that we are only using about 16% (FAO data) of the available farmland for agricultural production. Land is also needed for other purposes such as for animals to graze, to provide habitats for wildlife, etc. If, at present, only 16% of the world’s potential farmland is being used, there must be some room to maneuver. It is, however, generally argued in most third world countries that, except in a very few limited areas, there is not much scope to bring new lands into cultivation. Also, there are more serious problems. This may become apparent by looking at Figure 1.3, which is again FAO data, on per capita availability of food grains in the world, assuming that the food is distributed equally to everyone.

FIGURE 1.1 World population growth from 1960 to 2000.

According to the above data, world food production per person has actually been steadily increasing! This means that we have more food per person today than we had decades ago. Then why are there more people hungry and starving today? It is simply because there is both a surplus and a shortage of food—surplus where there is no need for the food and shortage where there is acute need for it. Clearly, the problem is more about distribution than production of a sufficient quantity of food. This problem could touch several points in this scenario— inadequacy or unwillingness in the distribution of food or inadequate processing, storage, and distribution facilities leading to spoilage of food. It is clear that more food and land are available in North America, where there is no food shortage. There is severe lack of agricultural land and resources in the populous third world countries, where the need for food is the greatest. When there is already so much surplus food in the affluent countries where there is more farmland, why would there be any incentive to bring more land to cultivation? Adapting more land to cultivation obviously becomes a less viable option because of this surplus availability. The hunger problems faced the world over are, therefore, not entirely due to a lack food in the world. The social structure worldwide requires a better understanding, redesign, and a more powerful UN intervention to accommodate the needs of the hungry population; otherwise, human starvation could someday lead to an “explosion” of some sort, whereby the thirdworld population may simply “take over the world,” creating worldwide chaos.

FIGURE 1.2 World food production growth (arbitrary scale) from 1960 to 2000.

FIGURE 1.3 World per capita food availability from 1960 to 2000.

In any case, the primary goal should be to conserve the food we have so it can possibly be distributed. We need to have an efficient distribution plan, so what we produce on the farm eventually reaches the kitchen table. It is generally estimated that 25 to 30% of what we produce is lost in the post-harvest chain and never reaches the consumer’s pot. Therefore, it sounds attractive to minimize these post-harvest losses so we conserve what we produce. This is a desirable alternative for many reasons. Wastage of food represents an economic loss. The economic loss increases as the food moves down the food pipeline, because to the cost of food that is lost must be added the cost of handling, transportation, storage, etc., up to that stage. The food supply is also significantly increased without bringing another acre of land into production and without using greater amounts of energy, water, and capital.

The first challenge is, therefore, to minimize the losses during the various postharvest operations and to keep the food as fresh as possible. In order to do so, one must first understand the various causes of post-harvest spoilage of fruits and vegetables and the various factors that influence these causes. Secondly, we must use those post-harvest conditions and operations that will result in extending the shelf life of the produce. The different causes of post-harvest food losses can be broadly grouped as 1) biological and microbiological, 2) chemical and biochemical, 3) mechanical, 4) physical, 5) physiological, and 6) psychological. Many of these factors have synergistic effects, and the combined effect of any two factors can be higher than the individual effects of the two together. Various factors can affect the causes of post-harvest spoilage. The biological factors include respiration, transpiration, ethylene production, compositional changes, physiological breakdown, etc. The environmental factors include temperature, relative humidity, atmospheric composition, light, and other factors (such as fungicides, growth regulators, etc). One should try to minimize losses due to each and every factor in order to extend the duration of post-harvest storage. The best procedure would involve harvesting the produce at the optimum stage of maturity, followed by quick cooling (by using one of the rapid cooling techniques, such as forced air cooling, vacuum cooling, hydrocooling, etc); packaging them appropriately to provide physical, mechanical, and functional support; and transferring them to an appropriate storage facility (regular and controlled atmosphere storage) where the temperature, relative humidity, air velocity, and atmospheric composition are set at the most appropriate level for the produce. Ideally, the produce would then be left in this primary storage until ready for final shipment to the retailer to ensure quick transfer to the consumer, who anticipates that the product will still be of high quality after the food has been taken out of the home refrigerator and cooked. It sounds simple, but the process is fairly complex and requires a lot of coordination in order to succeed. The main consideration in dealing with fresh produce is that it is living and needs to respire in order to stay alive. Respiration is both good and bad. It is necessary for sustaining life and supporting all the various activities in living cells. But it also depletes the storage reserves and breaks down macromolecules to provide the energy and metabolites for various cell functions. The storage quality of produce is inversely proportional to the rate of respiration. Hence, this aerobic respiration rate has to be maintained at some low level in order to keep the produce alive and, at same time, extend the shelf life. When dealing with foods of animal origin, it is a different ball game. The tissue is dead once the animal is slaughtered or when the fish is caught, and we are concerned with anaerobic respiration, rigor mortis, proteolytic changes, etc. But the principles of the use of refrigeration hold good here as well. Refrigeration is also the primary means of extending the shelf life of dairy products such as milk, yogurt, cheese, fruit juices, etc. These procedures (refrigeration, controlled atmosphere storage, etc.) will allow a temporary or short-term extension of their shelf life.

Food (whether an agricultural or animal product) is highly perishable. In spite of taking all precautions for post-harvest handling, it is impossible to keep all available food in its farm-fresh state. The only way to make it available for later use in distant markets is to convert it to a more stable form. Thus, the major emphasis of food processing is preservation or shelf-life extension by preventing undesirable changes in the wholesomeness, nutritive value, and sensory qualities. This is done by controlling chemical, biochemical, physiological, and microbiological activities. The food is most likely converted to other stable forms because it would be difficult to control the above activities while it is in the fresh state. Various techniques are used for this purpose:

- Removal of heat: Since most of the biological, biochemical, physiological, and microbial activities increase or decrease with temperature, temperature control (refrigeration) remains the most widely used method today to keep food fresh. Because the spoilage activities are not completely stopped, refrigeration only provides temporary shelf-life extension. On the other hand, freezing terminates most of these microbiological and physiological activities (except chemical and some enzymatic changes). The freezing process can provide a long storage life, especially when the product is frozen and stored at temperatures below −18°C.

- Addition of heat: Heat can preserve food by inactivating the enzymes, destroying the microorganisms of both spoilage and public health concern. If it is appropriately packaged to prevent recontamination, the food can be stored for extended periods of time. Pasteurization processes only deal with mild heat, aiming to provide short-term extension of shelf life, in combination with refrigeration, whereas the commercial sterilization process (canning) produces shelf-stable products. The heat treatment achieved during the cooking of foods also helps to render the food more safe and palatable.

- Removal of moisture: All life-sustaining activities require the use of water, available as free moisture in foods. By removing or reducing the moisture content, the food can be rendered stable, because most of the spoilage activities are stopped or retarded. This is the principle used in such processing applications as drying, concentration, and evaporation.

- Controlling water activity: It is not just the presence of moisture in foods that renders them unstable, it is the availability of moisture for their activities. Water activity is a measure of the available moisture. A water activity level of 0.75 is considered the minimum required for most activities. Water can be bound to salts, sugars, or other larger molecules, which makes it unavailable. Such conditions can exist in dried products, intermediate moisture foods, concentrates, etc.

- Addition of preservatives, sugar, salt, acid: These have specific roles in different products. Preservatives can selectively control the activities of microorganisms and enzymes. Sugar and salt can control the water activity. Some acids (for example, acetic acid—vinegar) have antimicrobial properties. Products such as jams, jellies, preserves, pickles, bottled beverages, etc. make use of such concepts.

- Other techniques: Other techniques, such as irradiation, exposure to ultraviolet light, high-intensity pulsed light, pulsed electric field, high pressure, etc., have different mechanisms for controlling the spoilage activity in foods and have been used for shelf-life extension.

- Secondary objectives: There are secondary objectives for food processing as well. They include diversification of products to provide variety, taste, nutrition, etc., to provide end-use convenience, to facilitate marketing, to prepare food ingredients through isolation or synthesis, and to produce nonconventional foods.

The purpose of this book is to address the basic principles and applications for major processing techniques of commercial importance. It is written in textbook format for teaching an undergraduate course in food processing. Both science and engineering principles are covered, highlighting the chemical and microbiological basis of food preservation and covering the mathematical basis for modeling and processing applications. Primary focus is given for three methods of preservation—thermal processing, freezing, and dehydration.

The book starts with this introductory chapter, which gives an overview of the food processing needs and principles. Most background information necessary for understanding the concepts described in other sections of this book is detailed in Chapter 2. Chapter 2 also includes such topics as units and dimensions, conversion factors, mass and energy balances, heat transfer principles, thermophysical properties, fluid flow, and rheology. Chapter 3 provides in-depth coverage on thermal processing. Chapter 4 focuses on refrigeration and freezing, Chapter 5 on dehydration, and Chapter 6 on other separation technologies.

2

Background Basics

This chapter provides comprehensive background material on an assortment of topics relevant to a better understanding of the concepts involved in the principles and applications of food processing techniques. Rather than discussing them in the individual sections, which often distracts the development and discussion of the primary topic in the individual chapter, these are pooled here in this chapter. Those who are familiar with these concepts can proceed directly to Chapter 3.

UNITS, DIMENSIONS, CONVERSIONS, COMMON TERMS, DEFINITIONS

A dimension is used to characterize a physical quantity under consideration. Fundamental dimensions are those from which others are derived. A system of units will represent an arrangement of measurement of different dimensions, either fundamental or derived. All systems have the following fundamental dimensions: mass (M), length (L), time (t), force (F), and temperature (T). In absolute systems, mass will be a fundamental dimension, whereas force will be a derived dimension. In gravitational systems, force will also be a fundamental dimension. It is important to point out that mass and weight are often used interchangeably. However, mass is defined as an amount of matter contained in a body, whereas weight is the result of the gravitational force exerted by mass.

MAIN SYSTEMS OF UNITS

A unit is used to determine the magnitude or size of the dimension under consideration. Two types can be distinguished—base units, which are dimensionally independent and used for one dimension, and derived units, which are combinations of various dimensions.

BASIC DIMENSIONS AND THEIR UNITS

In the metric system, generally designated as CGS in science, the units for mass, length, time, force, and temperature are g (gram), cm (centimeter), s (second), (dyne), and °C (centigrade), respectively. The unit of force is defined from Newton’s second law of motion...

Table of contents

- Cover Page

- Title Page

- Copyright Page

- Foreword

- Authors

- 1: Introduction

- 2: Background Basics

- 3: Thermal Processing

- 4: Low-Temperature Preservation

- 5: Food Dehydration

- 6: Separation and Concentration

- Appendix A

- Appendix B

- Appendix C

- References Cited

- Additional Reading Material

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Food Processing by Hosahalli S. Ramaswamy,Michele Marcotte in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Food Science. We have over one million books available in our catalogue for you to explore.