This is a test

- 640 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Architecture and Construction in Steel

Book details

Book preview

Table of contents

Citations

About This Book

This book provides a comprehensive guide to the successful use of steel in building and will form a unique source of inspiration and reference for all those concerned with architecture in steel.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Architecture and Construction in Steel by Alan Blanc,Michael McEvoy,Roger Plank in PDF and/or ePUB format, as well as other popular books in Architecture & Architecture General. We have over one million books available in our catalogue for you to explore.

Information

Part One | History of Iron and Steel |

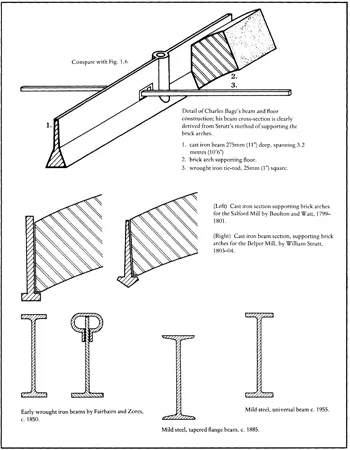

The development of cast iron and wrought iron beams in the 18th and 19th century. By kind permission of Alan Ogg.

1

The 19th century

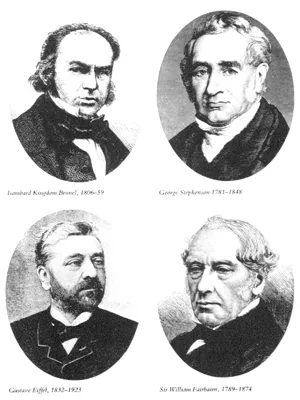

Dinnes Sharp

1.1 INTRODUCTION

It has often been claimed that the new spirit in building of the 19th century had little to do with architecture. Architects, it has been argued, were in the main preoccupied with stylistic matters rather than technical ones, producing architectural cloaks for public buildings such as the new town halls, opera houses, theatres, libraries and museums. The less stylistically inclined engineer was conversely building (and often inventing) new systems of construction and the structural shapes of bridges, furnaces, warehouses, derricks, workshops and factories as well as other utilitarian structures of the time.

Although this myth is not entirely true, substantially it remains a valid summary. The exceptions, it is now more readily acknowledged, provided the ‘contact points’ in the growth and development of new techniques, skills and means of expression in the construction industry. Having previously enjoyed both creative and technical freedoms in the construction of cathedrals, churches, cloth halls, towers and barbicans, architects and master masons had never really experienced the coincidence of untrammelled possibilities for a series of new materials, unprecedented social, political, economic and speculative opportunities. The lack of a consistent architectural style for a whole panoply of new building types was a constant embarrassment, even in the early years of the 19th century: ‘Architects harangued each other, laymen harangued architects, and the only point on which almost everyone . . . agreed was that the architecture of the immediate past, of the first years of the century was at the best boring and at the worst common’ [1].

It is perhaps too easy to chart the course of innovation and speculative prototypes as if they were themselves part of some great Darwinian scheme, as if a casual plan was at work in which an inevitable course was gradually being uncovered by curious, briUiant and inventive people. It was hardly that. Revolutionary yet simple means brought about the rapid growth of events that led to the introduction of lighter materials into the building industry. The industry had taken centuries to master the weightiness of stone, the massive nature of brick and the solidity of the surface volumes that result from the combination of these natural materials. Iron offered a multitude of new possibilities in a constructional sense, not the least of which was the desire to prefabricate and site assemble complex structures. To create wide spans and to form simply supported but transparent envelopes as shelters for activities and as protections against nature were somewhat simple minded design aims, they formed but the basis on which the new technology got underway. In the later medieval period stained glass windows were often strengthened by wrought iron framing members. Wrought iron cramps were also later introduced to reinforce masonry.

As designers reached for the sky in their efforts to create bigger and larger structures they pushed the possibilities of wrought iron to the known limits of the material. The 19th century saw some of the boldest experiments in comprehensive constructional techniques since the introduction of the arch. The experiments began with revisions to the simple elements of building. In Europe, iron roofing members were introduced in the 18th century in buildings for fire reasons also, particularly for theatres and warehouses. Victor Louis constructed a wrought iron roof for his Théâtre Franççais in 1786; other designers followed his methods with interest.

It is, however, bridges that provide a key introduction to the topic of historic cast and wrought iron. The earliest known examples that employed iron in their construction seem to be the Chinese chain bridges which are represented in the famous ‘Bridge (magic) myths’. An ‘iron bridge’ on a suspension principle crossed the Kin-Sha river in China in the 8th century. Chain bridges were common in Yunnan much earlier [2]. Iron was also employed in Pagoda construction certainly from the Sung period and perhaps earlier. Later examples are better known and significant advances in the early use of iron can be illustrated by reference to such famous British engineers as Brunei, Telford, the Stephensons and Rennie.

1.2 CAST AND WROUGHT IRON

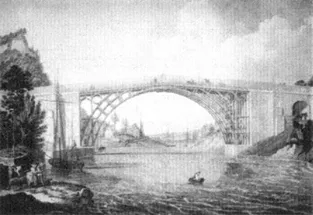

The modern story in fact starts with the work of the Darby Brothers at Coalbrookdale. They brought the new smelting process into common use, forming rough bars of ‘pig’ iron. However, cast and wrought iron had been used in a number of Gothic buildings. The concurrence of coal and iron ore measures at Coalbrookdale led to the most rapid advances in iron casting culminating in 1777–9 with the construction of the famous clear span ‘Ironbridge’ at Coalbrookdale over the River Severn (Fig. 1.1). The assembly of the cast iron components for this semi-circular bridge resembled the spokes of a gigantic wheel, with the elements put together using pins and bolts rather in the manner of an oak truss assembly with metal fastenings. There were technical limitations in making long lengths of cast iron, so the bridge comprises a whole series of short compression elements. The technical ingenuity in putting together the components to achieve a 100 ft span (30 m) was a remarkable achievement in terms of accuracy and workmanship. The designers understood the compression attributes of cast iron which, coupled with its low corrosion risk, achieved a viable arched bridge structure in the new material. It still stands today, the noble father of a family of cast iron bridges that covers the elegant Mythe Bridge at Tewkesbury (1823–6) to the climax of wrought iron suspension bridge construction over the Menai Straits (1819–26), both by Thomas Telford (1757–1834).

The reputation of West Midlands ironfounders was enhanced by their collaboration with the canal engineer Telford in developing solutions for wide span cast iron aqueducts, such as Pont-y-Cysyllte (1795–1805), carried on masonry piers. Flanged castings were used in this project, bolted together to form a box-like channel to support the water trough with flange arched elements below. The combined span of the 19 arches was 1001 ft (302 m) with a height of 120 ft (36 m) above the valley floor; each arch spanned 45 ft (13.5 m).

Telford saw the great potential of iron as a structural material but his background was that of a skilled stonemason. His approach was therefore largely empirical in the constructional use of cast iron, although he was one of the first engineers, together with John Smeaton (1724–92), to appreciate the scientific basis of structures and their European origins [3]. His confidence, however, was such that a proposal for a 600 ft (180 m) clear span bridge was made for London in 1800, a simple development of the arched span components used on canal bridges.

The engineering achievements in the early 19th century were fuelled by the post-Waterloo boom in Britain's economy and led to extensive road construction, many fine bridges, and finally to even greater engineering works linked with the expansion of the railway which included viaducts, railways sheds and stations as well as more bridges of a revolutionary design.

The engineering practice of Isambard Kingdom Brunei (1806–59) and his father Sir Marc Brunei (1769–1849) brought scientific principles to bear on engineering construction. Besides introducing mathematical calculations into structure, the skill of the Brunei partnership was also directed to the use of forged wrought iron using steam hammers to achieve structural sections with a wide range of applications such as bulbous ‘I-bars’ for ships and tees for rail tracks. These former were developed for building beams with extended webs and additional forged members to the lower flange.

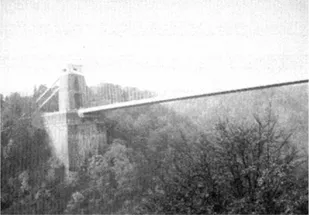

The inventiveness of Brunel can be seen in the first

Fig. 1.1 Ironbridge, Coalbrookdale 1777–9 (engineer Abraham Darby).

proposals for the Clifton Suspension Bridge (1831 but completed 1864, five years after his death) (Fig. 1.2). It had a 702 ft span and a width of 31 ft. Wrought iron chains and suspenders carry the cross framed road deck between the masonry towers. It is anchored back to the cliff abutment 245 ft above water level. The great Royal Albert, Saltash railway bridge, by contrast, was a tubular arched girder bridge raised off masonry towers, with a slung lattice for the rail deck below. It was partly built with ironwork reserved for Clifton but made up of 17 land spans and having a total length of 2220 ft (Fig. 1.3). Another wrought iron tubular bridge was constructed by Brunei over the Wye at Chepstow.

Another remarkable advance made by the Brunels was in ship construction (Fig. 1.4). Here they developed the first screw propeller driven iron ship capable of crossing the Atlantic. The ship’s construction comprised iron rib and deck beams and iron plating and rivets which were used for the first time in its construction instead of conventional timber planking. The Great Britain made her maiden crossing in 1845 and was followed within 10 years by a ship that was 680 ft (204 m) long and not exceeded in size until the launching of the Titanic. The wrought iron used by the pioneer engineers was produced in relatively small furnaces and prepared and worked to achieve specific shapes and strengths.

1.3 FORTH RAILWAY BRIDGE: FIRST STEEL STRUCTURE

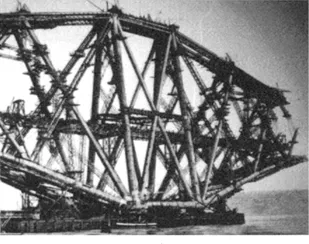

The production of mild steel followed the adoption of the converter process from 1856 onwards. The first large scale use of modern day steel in Britain was in the construction of the Forth Railway Bridge (Fig. 1.5), a fine, elegant tubular cantilever structure designed by Benjamin Baker and completed in 1890. Here the work embodied the latest technology with steel tubular trusses put together by riveted and

Fig 1.2 Clijion Suspension Bridge, Bristol 1831–64 (engineer I. K. Brunel).

Fig 1.3 Royal Albert Railway Bridge, Saltash 1852–9 (engineer I. K. Brunel).

Fig 1.4 SS Great Britain 1845 (engineer I. K. Brunel).

Fig 1.5 Forth Railway Bridge under construction, late 1880s (engineer Benjamin Baker).

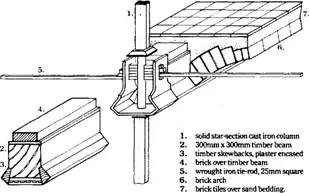

Fig 1.6 Strutt’s use of wooden beams and brick arches with cast iron columns. Courtesy Alan Ogg; Architccturc in Steel.

bolted work to achieve the tapered cantilevered trusses with multiple spans, max: 1710 ft (523 m). The advance to modern day steels meant that bridge designers finally had a mass produced material available of proven strength. Like wrought iron, it had the ability to be bolted, riveted or forged together to form the composite elements needed in this kind of large scale bridge construction.

1.4 MILL BUILDINGS IN BRITAIN

Cast iron was extensively used in mill buildings in Britain...

Table of contents

- Cover

- Architecture and Construction in Steel

- Full Title

- Copyright

- Contents

- Contributors

- Preface

- Acknowledgements

- Introduction

- Part One History of Iron and Steel Construction

- Part Two Materials

- Part Three Principles of Steel Framing

- Part Four Steel Construction

- Part Five Secondary Steel Elements

- Part Six Outstanding Contemporary Steel Architecture

- Appendix A

- Appendix B

- Index of architects and engineers

- Index of buildings

- Subject index