![]() Materials and Failure Mechanisms

Materials and Failure Mechanisms![]()

28 A FAILURE OF A MATERIAL OR OF ADVANCED TECHNICAL EDUCATION – IMPLICATIONS OF AN UNEXPECTED MATERIAL FAILURE

R. FIEDLER

Department of Microelectronics, Technical University, Brno, Czech Republic

Abstract

This paper describes a case of unexpected material failure in an electronic component. The failure demonstrates the limitations of even the best quality-control programme. If European electronics industries are to remain competetive, total quality management within the narrow environment of the company will not be enough. The concepts of total quality management must be extended to the global environment surrounding production plants. This paper focuses on the implications of global quality management in the advanced technical education system.

Keywords: diagnostics, education, electronic component, iron-nickel alloy, material failure, quality control.

1 Introduction

Failure problems in modern electronic systems are usualy minimized thanks to the total quality management in the electronic industry. A very important stage in introducing the quality programme is the Failure Mode and Effect Analysis (FMEA) [1]. It helps the producer to find all the reasons for a given failure and take essential precautions against it. Due to the world wide implementation of Total Quality Management (TQM) the failure of any product is very harmful for producers who compete for ISO 9000 quality certification [2] and/or for a place on the Qualified Manufacturers List.

If by chance a repeated failure of an electronic component appears the manufacturer may choose from a broad spectrum of methods for material diagnostics. However, if the material failure is due to an error in a human controlled technology we do not speak only about a failure but also about the effect of human factor.

The paper will briefly describe a case of material failure in an electronic chip component fabricated from imported parts. The results of material analysis, however, can be hardly understood in terms of accidental material failure alone.

2 The analysed problem

In the electronic industry bonding is generally the most expensive phase in the manufacturing process [3]. The quality of bonds is usually tested mechanically. In some electronic chip components used for Surface Mounted Technology, band leads are used instead of conducting wires for terminations. Recently, we have analysed reasons for the low strength of soldered bonds and for the apparently spontaneous fracturing of chip terminations. We found that the low quality of bonds was caused by a low adhesion of Pb-Sn solder due to unusually high amounts of gas present in plated layers.

Material engineers know that a high amount of gas is released during electrochemical plating. The technology of electroplating is so developed that the amount of gas in a plated layer can be controlled and easily kept at minimum.

The problem of poor adhesion was easily solved and the subcontractor promised to maintain the quality of plated layers. A couple of months later, however, another customer observed spontaneusly fractured termination on some chips. Standard methods of analytical Scanning Electron Microscopy (SEM) did not reveal any changes in the structure either in the composition of samples taken from the plated band of material used for manufacturing terminations.

N.B. The effect of poor adhesion and mysterious fracturing appeared when the fabrication of the electronic component was transfered to an other country with cheaper labour market. As the former subcontractors known for their high quality of production were still contracted the first conclusion of the top management was: “The cheaper the labour market the lower the quality of fabrication.”

2.1 The structure and composition of analysed chip termination

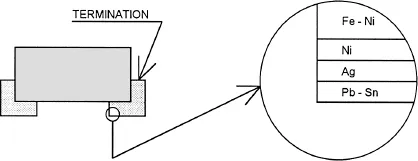

The analysed band leads used for chip terminations are made from an iron-nickel matrix, plated on both sides with layers of nickel, silver and Pb-Sn solder (Fig. 1).

Fig. 1. A chip component and structure of termination schematic

2.2 Used experimental method and results

As the standard method of analytical SEM failed to find any natural reason for spontaneous fracturing it was necessary to take the unusual measure of preparing a sample for SEM observation. Trial and error was used to find a suitable etchant for etching the polished surface of a cross section through the sample. After proper chemical etching a very fine pitting of the surface was observed through SEM. The pits were 0,001 mm in size. The average distance between pits was 0,015 mm. X-ray spectral analysis showed high concentration of aluminium in pitted areas. The presence of aluminium, however, was not found in the sample prepared for SEM and X-ray spectral analysis by standard methods.

The only explanation found for this observation is based on the presumption that very fine alumina (Al2O3) particles must have been dispersed in the Fe-Ni matrix. The size of the alumina particles was estimated to be in order of 0.000 01 mm; just under the resolving power of a standard SEM. The presence of aluminium was later proved and documented through x-ray spectral analysis on the fractured surfaces. The fracture surface contained measurable concentrations of aluminium.

3 Discussion

Alumina particles are not ductile and their occurance in Fe-Ni matrix may have very harmful effect on the mechanical properties of terminations. During fabrication of the chip, the terminations are bend. The stress around non-ductile particle produces a microcavity and/or microcraks in the Fe-Ni matrix. This microcavity acts as a nucleus for later cracks and fracture.

Alumina particles might cause further damagewhen chip components are used in an electronic device. Due to the elastic strain around the alumina particles, the atoms of gas dissolved in the plated layers of the terminations would slowly migrate to the particle and form a void filled with gas. When the chip component is then heated up by Joule heat losses during operation, up-hill diffusion is enhanced, microcracks in a termination start to grow in size, and the electronic component after some time fails.

The alumina particles found in the Fe-Ni matrix of terminations are so very tiny that their presence cannot be detected by any standard method of material diagnostics. Their occurrance of this size and amount in Fe-Ni alloy is very unusual. They would have had to have been introduced to the material during casting and/or during rolling of the Fe-Ni plates. Having analysed the failure we have had to ask the old prosecutor’s question: “Who benefited?”

3.1 The role and limitations of diagnostics ...