- 252 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

More Baking Problems Solved

About this book

When things go wrong in the bakery, the pressures of production do not allow time for research into the solution. Solving these baking problems has always been the province of 'experts'. However, with a methodical approach, keen observation and a suitable reference book then the answers to many baking problems are more easily identified.The companion volume to the popular Baking problems solved, More baking problems solved contains an updated guide to problem solving and the answers to further frequently asked questions Once again arranged in a practical question-and-answer format, it will enable busy bakery professionals to understand causes of their problems and implement solutions.Written by two leading experts and based on a wealth of practical experience, More baking problems solved is invaluable to all bakery professionals, bakery students, food technologists and product developers.

- An updated guide to problem solving that provides answers to further frequently asked questions and baking

- An essential reference and problem solving manual for professionals and trainees in the industry

- An ideal companion volume to Baking problems solved

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Problem solving: a guide

‘You can’t solve a problem with the same type of thinking that caused it’

Einstein

The quote from Einstein may seem like a statement of the obvious but after many years of experience in the baking industry we have seen that the obvious is constantly overlooked when it comes to trying to solve problems or develop new products and processes. Indeed there is relatively little difference between solving a problem and creating a new product, in both cases you are required to use different thinking from that you would normally use for established products and processes. In essence both scenarios are vindications of Einstein’s view.

Problems that show as unexpected variations in bakery product quality do occur from time to time. Often considerable time, effort and money are required to identify the causes and solutions concerned. Unexpected quality variations are not the exclusive province of any particular size of manufacturing unit: they can occur in both large and small bakeries. Nor are they exclusive to the production bakery: even the best-controlled test bakery or laboratory can experience unexpected fluctuations in product quality.

There is no magic to problem solving. It is normally achieved through critical observation, structured thought processes and access to suitable sources of information. In this chapter we offer a guide to some of the methods that might be employed when trying to solve bakery-related problems. In doing so we must recognise that baking is a complex mixture of ingredient and process interactions so that the solutions to our problems may not always be instant in nature and because ingredients and processes change, new solutions are always being discovered. The complex interactions which underpin baking dictate that there are seldom unique solutions to individual problems. In the majority of cases individual quality defects are overcome by changing a number of ingredient and process factors, some of which will be apparently unrelated, though careful study will often reveal that relationships do exist even where they are masked by more prominent effects.

1.1 How to problem solve

Successful problem solving usually requires a methodical approach. It is perfectly possible to stumble quickly on the required solution by chance but more often than not a haphazard approach to problem solving is wasteful of time, resources and money. In addition, stumbling on the solution by chance often means that the root cause of the problem remains unidentified and the opportunity is lost for the systematic assembly of information which may be valuable for solving similar problems in the future. Not all problems are solved using exactly the same approach but the critical elements of the problem-solving process are largely common.

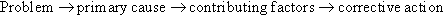

In problem solving we normally move from the problem to the cause and finally to the corrective action. However, we must recognise that on many occasions the manifestation of a particular problem does not necessarily have a unique and identifiable cause and so there may be other intermediate steps to take into account in determining the real cause of the problem. This situation can be described schematically as follows:

Or in more simple terms as:

The basic process becomes apparent if we consider two examples of problems in bread making; the first, low bread volume, and the second, collapse of the sides of an open top pan loaf, often referred to as ‘keyholing’ (BPS, pp. 57–8).

Low bread volume

Externally we observe that the bread is smaller than we expect and this may also have led to a paler crust colour because of the poorer heat transfer to the dough surface during baking. Internally the cell structure may be more open than usual.

Since bread volume is a consequence of expansion of the dough by carbon dioxide gas from yeast fermentation and the retention of that gas within the dough matrix (Cauvain, 2007a), there are two potential primary causes of this problem – lack of gas production and lack of gas retention. To separate the two we will need more observations, and an important one will be whether the rate of expansion of the dough in the prover and oven was normal or slower than usual. If the latter was the case then the primary cause of the problem is likely to be lack of gas production, and potential contributing factors may include the following:

• yeast activity or level too low;

• lack of yeast substrate (food);

• dough temperature too low;

• proving temperature too low;

• proving time too short;

• salt level too high;

• proving temperature/time/yeast combination incorrect.

On the other hand, if the proving had been at a normal rate and there was a lack of oven spring, then this would lead us to recognise that the problem would be lack of gas retention. In this case the list of potential reasons for the problem includes:

• improver level too low;

• incorrect improver formulation;

• combination of improver and flour too weak for the breadmaking process being used;

• enzymic activity too low;

• energy input during mixing too low;

• mixing time too short;

• dough temperature too low.

Note that the ‘dough temperature’ too low appears in both lists because of its effect on yeast activity and the effectiveness of the functional ingredients in the improver, especially if ascorbic acid is used.

Keyholing (BPS, pp. 57–8)

Externally we observe there is a loss of bread shape but only at the sides of the product. Internally we may see the formation of dark-coloured, dense seams, often referred to as cores. The centre crumb may be more open than we normally expect for the product concerned.

Why has this happened? Clearly we have no problems with gas production, since there is no evidence for slow proving and the bread had good volume. We have clearly retained the carbon dioxide gas produced, otherwise the bread would have low volume as described above. In this case the over-expansion...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Preface

- 1: Problem solving: a guide

- 2: Flours and grains

- 3: Other bakery ingredients

- 4: Bread and fermented products

- 5: Cakes

- 6: Biscuits and cookies

- 7: Pastries

- 8: Other bakery products

- 9: What is/are/why/how?

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access More Baking Problems Solved by Stanley P. Cauvain,L S Young in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Food Science. We have over one million books available in our catalogue for you to explore.