Membrane Technology

A Practical Guide to Membrane Technology and Applications in Food and Bioprocessing

- 312 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Membrane Technology

A Practical Guide to Membrane Technology and Applications in Food and Bioprocessing

About This Book

Membrane technology is a rapidly developing area, with key growth accross the process sector, including biotech separation and biomedical applications (e.g. haemodialysis, artificial lungs), through to large scale industrial applications in the water and waste-water processing and the food and drink industries. As processes mature, and the cost of membranes continues to dramatically reduce, so their applications and use are set to expand. Process engineers need access to the latest information in this area to assist with their daily work and to help to develop and apply new and ever more efficient liquid processing solutions.

This book covers the latest technologies and applications, with contributions from leading figures in the field. Throughout, the emphasis is on delivering solutions to practitioners. Real world case studies and data from leading organizations -- including Cargill, Lilly, Microbach, ITT -- mean this book delivers the latest solutions as well as a critical working reference to filtration and separation professionals.

- Covers the latest technologies and applications in this fast moving bioprocessing sector

- Presents a wide range of case studies that ensure readers benefit from the hard-won experience of others, saving time, money and effort

- World class author team headed up by the Chair of Chemical Engineering at Oxford University, UK and the VP of Plant Operations and Process Technology at Cargill Corp, the food services company and largest privately owned company in the US

Frequently asked questions

Information

Chapter 1

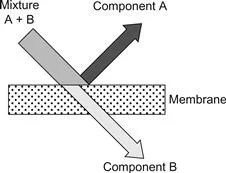

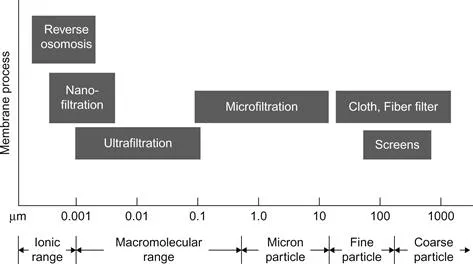

Fundamentals of Pressure-Driven Membrane Separation Processes

Table of Contents

1.1 Introduction

1.2 Processes

1.2.1 Process Classification

1.2.2 Definitions

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- About the Editors

- About the Contributors

- Chapter 1. Fundamentals of Pressure-Driven Membrane Separation Processes

- Chapter 2. Challenges of Membrane Technology in the XXI Century

- Chapter 3. Membrane Processes in Fruit Juice Processing

- Chapter 4. Membrane Application in Soy Sauce Processing

- Chapter 5. Application of Membrane Technology in Vegetable Oil Processing

- Chapter 6. Membrane Applications in Monoclonal Antibody Production

- Chapter 7. Membrane Processes for the Production of Bulk Fermentation Products

- Chapter 8. Membrane Technologies for Food Processing Waste Treatment

- Chapter 9. Practical Aspects of Membrane System Design in Food and Bioprocessing Applications

- Chapter 10. Membrane Fouling and Cleaning in Food and Bioprocessing

- Chapter 11. US Regulatory Approval of Membrane Technology

- Index