eBook - ePub

Solid-Liquid Filtration

Practical Guides in Chemical Engineering

- 136 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Solid-Liquid Filtration

Practical Guides in Chemical Engineering

About this book

Practical Guides in Chemical Engineering are a cluster of short texts that each provides a focused introductory view on a single subject. The full library spans the main topics in the chemical process industries that engineering professionals require a basic understanding of. They are 'pocket publications' that the professional engineer can easily carry with them or access electronically while working. Each text is highly practical and applied, and presents first principles for engineers who need to get up to speed in a new area fast. The focused facts provided in each guide will help you converse with experts in the field, attempt your own initial troubleshooting, check calculations, and solve rudimentary problems.

Solid-Liquid Filtration covers the basic principles and mechanisms of filtration, filtration testing including filter aids and filter media, types of filtration systems, selection of filtration systems and typical operating and troubleshooting approaches. This guide also discusses general applications and tips for process filtration and can be utilized by process engineers as a framework for "idea-generation when analyzing filtration for an operating bottleneck issue or a new process development problem.

- Practical, short, concise information on the basics will help you get an answer or teach yourself a new topic quickly

- Supported by industry examples to help you solve a real world problem

- Single subject volumes provide key facts for professionals

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Introduction

An introduction to a practical guide to solid–liquid filtration intended to better enable project engineer problem solving. This initial chapter serves as an introduction to the fundamental concepts and terms process engineers need to understand. An overview of filtration, filtration equipment categories, principals and mechanisms, filter media, coagulation and flocculation, surface charges, and filter rating systems are all initially explored.

Keywords

Filtration; filtration equipment; filter media; coagulation; flocculation; surface charges; filter rating systems

Solid-liquid filtration may not have the glamour of investigating blackmail and burglary, extortion and espionage, or murder and mayhem. Yet, process engineers can still learn many things from Sherlock Holmes and Dr. John Watson. While Sir Arthur Conan Doyle’s fictional characters may never solve real-life process filtration problems, they prove time and again that there is no benefit to jumping to conclusions. The duo’s sleuthing also benefits from working together to recreate events. Often Holmes talks through his theories to Watson—only then do gaps and inconsistencies become apparent. Additionally, Holmes and Watson apply the problem-solving skills such as the occasional silence, employing distancing and learning to tell the crucial from the incidental (Konnikova, 2013).

This practical guide to solid-liquid filtration is intended to better enable the inner Sherlock (or Watson) of engineers. Most university curriculums do not cover solid-liquid filtration, leaving many engineers clueless as to where or how to begin. This guide then will provide a framework to analyze and think about process filtration problems. It is not a “how to book” explaining in detail how to conduct tests or how to scale up from data; that is the purview of the equipment suppliers with deep knowledge of their individual technologies.

The information in this guide, gathered from over 30 years of experience, instead covers basic principles and mechanisms of filtration, filtration testing, including filter aids and filter media, types of filtration systems, selection of filtration systems, and typical operating and troubleshooting approaches. General applications and tips for process filtration are also included to better enable “idea-generation” for process engineers when analyzing filtration for an operating bottleneck issue or a new process development problem.

This chapter serves as an introduction to the fundamental concepts and terms process engineers need to understand. An overview of filtration, filtration equipment categories, principles and mechanisms, filter media, coagulation and flocculation, surface charges, and filter rating systems is initially explored in this chapter.

Filtration Overview

Process engineers really do have to employ their own kind of sleuthing, for selecting the right type of liquid/solid separating equipment is not a simple task. The wide range of equipment that might be employed and the at times illogical solutions required can cause further confusion among those who have no intimate knowledge of the processes. A further complication is that there are only two basic principles of liquid/solid separation, which means that equipment that might not be the best choice can still be made to work although, of course, sacrificing efficiency. This requires one to be extra careful when working with suppliers who only offer one type of equipment. The solution they are offering may, perhaps, be “made” to work, but may not necessarily be the smartest choice. For these reasons it is useful for engineers confronted with a separation problem to carry out their own basic evaluations of possible or probable solutions and to, above all, establish which routes not to follow.

It is hoped that this guide will enable the engineer to arrive at one, two, or three types of equipment that have an above-average chance of being right for the job, while also helping to eliminate those which are unsuitable. Having narrowed the field of options, the engineer has to calculate the strengths of weaknesses of each system through practical field pilot tests of actual machines and speaking with and visiting, if possible, the provisionally selected equipment’s users.

Filtration Equipment Categories

There are several approaches to categorizing solid-liquid filtration equipment. As a result, when beginning a project, the opening question is how best to begin.

First, the engineer must decide whether the process is a batch or continuous process. This is not as simple as it sounds. For example, while the reaction/precipitation can be batch or continuous, the solid-liquid equipment can also be batch or continuous. Further, it is necessary to examine the downstream process and determine whether this process is batch or continuous. Most often, a continuous process is more efficient. However, other ideas must be considered such as time in the reactor, crystal sizing/breakage, solids handling (or alternatively, whether the process can handle a concentrated slurry rather than solids), drying time, and other parameters. In summary, a review of the entire process is necessary before determining how best to begin.

Having reviewed the process, the next factor to consider is what type of discharge is required: batch or continuous, dry solids, wet solids, or concentrated slurry. Further, the engineer must determine if the solids are the product or the liquid is the product or possibly both components are required. Besides these questions, another decision impacting any cost analysis is whether this is a manual or automatic operation. For instance, are the solids directly discharged to the downstream process, moved by conveyors, totes, or intermediate bulk containers (IBCs), or are other systems employed? Even with this information gathered, there is still more initial information needed.

Finally, the engineer must examine the amount of solids to be filtered. For example, does the process slurry contain “high solids,” which could be up to 50–60% solids, or low solids, such as 2–5% down to trace amounts in the parts per million (PPM) level.

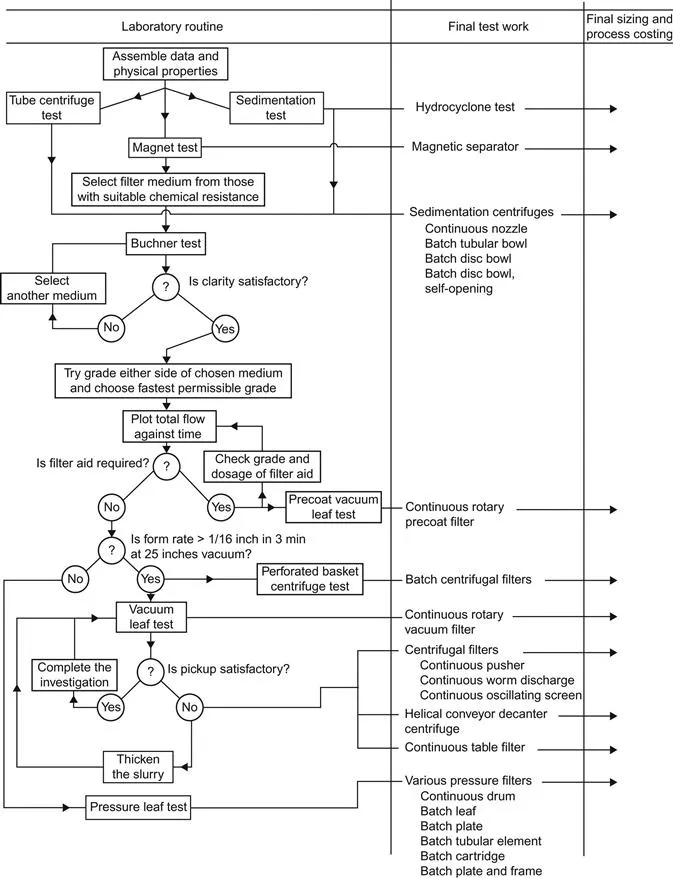

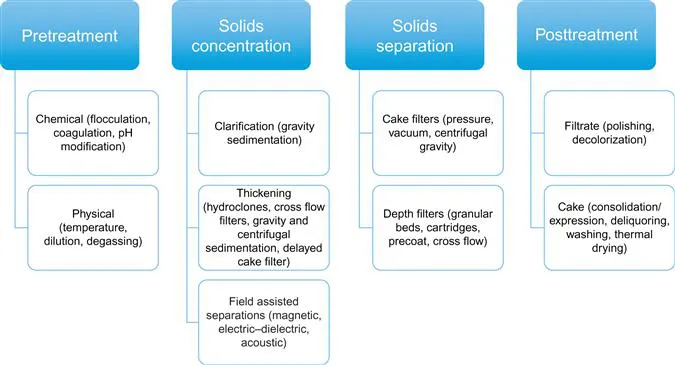

With all the above information in hand, the engineer can finally determine the best starting point. Just as Holmes and Watson agree that checklists and guides are important for problem solving, there are also several decision guides that have been published over the years. Davies (1965) proposed a scheme for selecting solid-liquid filtration equipment based upon cake dryness required, cake washing, filtrate clarity, and crystal breakage (Figure 1.1) (cited in Carpenter, 2013). Chase and Mayer (2003) offered a different approach looking more closely at the process including pretreatment, solids concentration, solids separation, and posttreatment (Figure 1.2). While these types of guides may be cumbersome, they do provide a good overview of what types of equipment are possible.

Principles and Mechanisms

The two basic principles of solid-liquid filtration are to either separate liquids from solids or filter solids from liquids. This would suggest employing one of two basic solutions:

1. Either the solids have a tendency to go one way and the liquid the other way (i.e., separation), or

2. One must find a hole smaller than the solids which one wishes to capture (i.e., filtration).

Yet in spite of there being only two principles, there are over 100 different types of equipment available, many with their own variations.

As this guide focuses on solid-liquid filtration, suspended solids are removed from liquids either on the surface (cake filtration) or within the depth of the filter medium. The depth of the filter media can be the filter media itself, the cake, or the filter aid. Regardless of the surface or depth filtration there are three mechanisms for removal: inertial impaction, diffusional interception, or direct interception.

Inertial Impaction

Particles in a fluid have a mass and velocity and hence have an associated momentum. As the liquid and entrained particles pass through a filter media, the liquid will take the path of least resistance and will be diverted around the fiber. The particles, because of their momentum, tend to travel in a straight line and, as a result, those particles located at or ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- List of Figures

- List of Tables

- About the Authors

- Acknowledgments

- Chapter 1. Introduction

- Chapter 2. Filtration Testing

- Chapter 3. Types of Filtration Systems

- Chapter 4. Combination Filtration

- Chapter 5. Filtration Selection

- Chapter 6. Commissioning and Operation

- Chapter 7. Conclusion

- Appendix. Paint Filter Liquids Test

- Glossary of Important Filtration Terms

- Suggested Further Reading Online

- References

- Bibliography

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Solid-Liquid Filtration by Barry A. Perlmutter,Barry Perlmutter in PDF and/or ePUB format, as well as other popular books in Design & Industrial Design. We have over one million books available in our catalogue for you to explore.