The movement of one solid surface over another is fundamentally important to the functioning of many kinds of mechanisms, both artificial and natural. The subject of this book, tribology, is defined as ‘the branch of science and technology concerned with interacting surfaces in relative motion and with associated matters’, and includes the study of friction, wear, lubrication and the design of bearings.

Mechanical systems in which surfaces do not slide or roll against each other are rare, and tribology is therefore a key enabling technology with very wide application. Progress in understanding the surface interactions that lie at the heart of tribology has demanded the skills of mechanical engineers, materials scientists, physicists and chemists; in the context of bio-tribology which concerns living organisms, the discipline becomes even wider and includes the medical and biological sciences. Advances in tribology have underpinned much of the world's engineering progress. Its reach extends to all aspects of modern technology, in the broadest sense of the word, in which surfaces move against each other, from transport and power generation to medical engineering, food science and cosmetics.

Although the subject of tribology is much wider than a study of friction, friction does play a central role in the performance of many mechanical systems. In some cases, low friction is desirable and even essential. The satisfactory operation of joints, for example, whether hinges on doors, human hip joints or bridge supports, demands a low friction force. Work done in overcoming friction in bearings and gears in machines is dissipated as heat, and by reducing friction we can achieve an increase in overall efficiency. But low friction is not necessarily beneficial in all cases. In brakes and clutches, adequate and controlled friction is essential to dissipate kinetic energy and transfer torque; high friction is similarly desirable between a vehicle tyre and the road surface, just as it is between the human foot and the ground for walking.

Whenever surfaces move over each other, wear will occur: damage to one or both surfaces, generally involving progressive loss of material. Sometimes the wear is imperceptibly slight, but it can also be extremely rapid. In most cases, wear is detrimental, perhaps causing increased clearances between the moving components, unwanted freedom of movement and loss of precision. It often leads to vibration, to increased mechanical loading and yet more rapid wear, and sometimes to fatigue failure. The loss by wear of relatively small amounts of material can be enough to cause complete failure of large and complex machines, and there are unfortunately cases where the root causes of major engineering disasters can be traced back to wear. High wear rates, however, are sometimes desirable. Grinding and polishing, for example, are widely used manufacturing processes that employ wear to remove material in a controlled manner, and an initial small amount of wear is often anticipated and even welcomed during the ‘running-in’ process in some kinds of machinery.

A key method of reducing friction, and often also wear, is to lubricate the system in some way, and the study of lubrication is very closely related to that of friction and wear. Even when an artificial lubricant is not added to a system, components of the surrounding atmosphere (especially the oxygen and water vapour in the air) often play a similar role and must be considered in any study of the interaction of the surfaces.

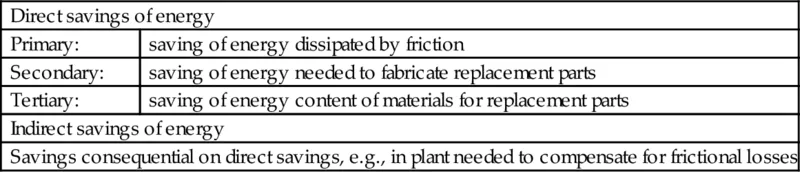

The word ‘tribology’ (from the Greek: τριβος=rubbing or attrition) was first coined in 1966 by a UK government committee, although friction, lubrication and wear had been studied for many years before then and have a long and fascinating history. That committee also made an estimate of the savings that could be made by UK industry if known tribological principles were widely applied. Similar exercises have subsequently been carried out in several other countries. Their conclusions are all in broad agreement: that at least 1% of the gross domestic product might be saved with minimal further investment in research, and that the potential for even larger savings might exist with further research. The savings arise from several sources. The original survey identified the savings listed in Table 1.1. The reduction in energy consumption through reduced friction was, in money terms, rather a small component of the total; savings in maintenance and replacement costs, in losses consequential upon breakdowns, and in investments through the increased life of machinery were at that time much more important. A subsequent survey in the UK, taking account of the relative increase in the cost of energy since 1966, focused on the savings in energy that can be made by improved tribological design, and identified the kinds of savings shown in Table 1.2.

Table 1.1

Methods by which financial savings could be made through improved tribological practice in UK industry. The proportions represent proportions of the total annual saving (which was estimated at £515 million at 1965 prices)

| Savings in maintenance and replacement costs | 45% |

| Savings in losses resulting from breakdowns | 22% |

| Savings in investment through increased life of plant | 20% |

| Reduction in energy consumption through lower friction | 5% |

| Savings in investment through greater availability and higher efficiency | 4% |

| Reduction in manpower | 2% |

| Savings in lubricant costs | 2% |

information from HMSO, 1966. Lubrication (Tribology) Education and Research. UK Department of Education and Science

Table 1.2

Methods by which savings of energy could be made through improved tribological practice in UK industry

| Direct savings of energy |

| Primary: | saving of energy dissipated by friction |

| Secondary: | saving of energy needed to fabricate replacement parts |

| Tertiary: | saving of energy content of materials for replacement parts |

| Indirect savings of energy |

| Savings consequential on direct savings, e.g., in plant needed to compensate for frictional losses |

information from Jost, H.P., Schofield, J., 1981. Proc. Inst. Mech. Engrs. 195, 151–195

Substantial advances in tribological understanding and in the application of that knowledge have occurred since the word ‘tribology’ was first defined. We have only to look at the advances in road and air transport, power generation, information technology, manufacturing processes and medical engineering to see important examples. But further development will undoubtedly occur, and it is more important than ever that an understanding of the principles of tribology forms part of the education of every engineer and applied scientist. There is now an increasing, and overdue, awareness of the imperative to conserve the resources of our planet, including fossil fuels and materials. In reducing the environmental impact of human activity, we need not only to reduce the atmospheric release of fossil carbon and generate energy in sustainable ways, but also to use materials, whether in capital equipment or in consumables such as lubricants, in a sustainable and environmentally-friendly manner. Not only should the correct application of tribological principles lead to longer-lasting, more energy- and resource-efficient products, but there are also situations where their neglect can lead to una...