1.1 Introduction

Animal fibres such as wool, cashmere and alpaca are highly prized when made into garments since these exhibit desirable properties such as soft touch, warmth, beautiful drape, excellent comfort in wear and, using modern synthetic dyes, unparalleled colouration possibilities with very few shade restrictions. Leeder1 points out that wool has been bio-engineered over millions of years to be worn next to an animal’s skin, and is thus better than other types of fibres in terms of comfort in wear; it possesses the properties of absorbing up to 30% of its own weight of water without feeling wet, and even giving out heat when it absorbs water. Despite the above strong positives it has to be noted that wool makes up less than 5% of the textile market, cotton and synthetic fibres making up the bulk – it would not be possible for wool growing to increase significantly and therefore wool must position itself mainly in the desirable ‘luxury’ item sector of the market. There are also performance disadvantages, which are not present in garments made from the other textile fibres; these include felting shrinkage (in knitwear this can be as high as 60%) during household laundering procedures, the need to scour the raw wool to remove lanolin, soil and seeds, and attack by moths and beetles during garment storage.

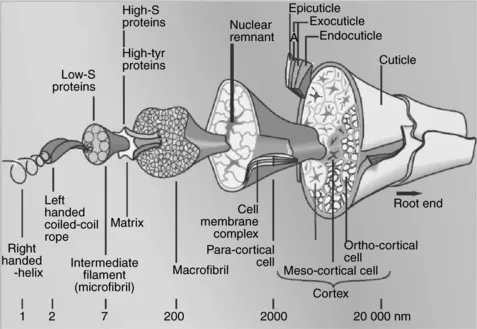

Wool scientists are well aware of the beautiful composite structure of the wool fibre; a single fibre is made up of many thousands of different proteins and even some 15% of non-protein material; nature has designed, through evolution, each of these components to play a role in protecting the animal from the elements and in maximising the animal’s comfort. The widely acclaimed, classic diagram showing the amazing complexity of the fibre, produced by Fraser and co-workers at Commonwealth Industrial Scientific Organisation (CSIRO)’s Division of Protein Chemistry in Melbourne, is shown in Fig. 1.1.

1.1 The microscopic structure of a wool fibre.

Not shown in this diagram is the F-layer which coats the epicuticle with a hydrophobic barrier; the classic studies by CSIRO scientists and others have established that this layer is made up of fatty acids covalently bonded to the fibre through thiol ester bonds at the cysteine site. The major constituent of this lipid material is 18-methyleicosanoic acid. The proteins in the epicuticle are highly disulphide cross-linked (i.e. cystine rich); in fact in the A-layer one in every 2.5 residues is cystine, making these surface proteins as hard as hoof material. These observations are crucial in understanding dye-diffusion processes when dyeing wool from aqueous solution as the surface structure creates a barrier to dye diffusion.

The marketplace is increasingly sensitive to possible negative impact of processing products on the environment; this has implications across the whole range of manufacturing processes used. This statement actually has profound implications for the finisher, dyer and printer of wool materials. In this context heavy metals present in dyes or in dyeing processes are important issues; although reactive dyes are being used more and more as replacements to produce dyed materials having high wet-fastness properties they do not give the same level of light-fastness in pale depths as do dyeings produced with pre-metallised or after-chrome dyes.

Compared to cotton and synthetic fibres, wool lacks brilliance in white and pastel shades and this has been seen as a major market issue; resolution of this problem will come from further research into improving the photo-stability of the base wool fibre2,3 and developing novel bright chromophores, even those not normally suited for dyeing wool.

To prevent felting shrinkage processes based on chlorination pretreatments are often used but these give relatively high amounts of Absorbable Organo Halogen (AOX) residues – the colourist has to be aware that up to 1000 mg/L AOX can be discharged from dye-houses dyeing these pre-treated substrates; it is vital that such pre-treatments are replaced by non-chlorine surface oxidation processes without adversely affecting dyeing properties.

Wool and other animal fibres undergo ‘setting’ reactions during dyeing, the extent of these depending on bath pH, time and temperature; the amount of set imparted influences final fibre strength and other properties such as yarn bulk. The interesting sulphur chemistry behind these reactions will be reviewed, emphasising the value of using so-called anti-setting agents in the dyeing process to improve final wool quality.

Ink-jet printing textile fabrics is now well established; in particular this procedure is ideally suited to wool printing; wool printing was a very small-scale activity in the past since screen printing required considerable investment in preparing and storing screens which could not be justified in terms of the short run-lengths involved. The special factors limiting the rapid adoption of such digital technologies for wool fabric printing will be considered.

1.2 Overview of industry practice

Prior to dyeing wool has to be scoured in the so-called raw state to remove dirt, soil, some vegetable matter, suint and lanolin or wool grease; scouring is usually carried out with non-ionic detergent and optionally sodium carbonate at 40–50 °C. This cleaned loose wool is then combed or carded to remove residual vegetable matter; combing is done on longer fibres to produce tops which are then spun on the worsted yarn system; the woollen system tends to use carded, shorter, coarser fibres. Wool may be dyed in the raw, loose fibre form, top form, or in yarn form or in piece form; dyeing is typically carried out at the boil for usually 1 h, although with current high energy costs there is increasing interest in reducing dyeing temperatures.

In the current high fashion industry it is more desirable to leave colouration to the l...