- 654 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Handbook of Laser Welding Technologies

About This Book

Laser welding is a rapidly developing and versatile technology which has found increasing applications in industry and manufacturing. It allows the precision welding of small and hard-to-reach areas, and is particularly suitable for operation under computer or robotic control. The Handbook of laser welding technologies reviews the latest developments in the field and how they can be used across a variety of applications.Part one provides an introduction to the fundamentals of laser welding before moving on to explore developments in established technologies including CO2 laser welding, disk laser welding and laser micro welding technology. Part two highlights laser welding technologies for various materials including aluminium and titanium alloys, plastics and glass. Part three focuses on developments in emerging laser welding technologies with chapters on the applications of robotics in laser welding and developments in the modelling and simulation of laser and hybrid laser welding. Finally, part four explores the applications of laser welding in the automotive, railway and shipbuilding industries.The Handbook of laser welding technologies is a technical resource for researchers and engineers using laser welding technologies, professionals requiring an understanding of laser welding techniques and academics interested in the field.

- Provides an introduction to the fundamentals of laser welding including characteristics, welding defects and evolution of laser welding

- Discusses developments in a number of techniques including disk, conduction and laser micro welding

- Focusses on technologies for particular materials such as light metal alloys, plastics and glass

Frequently asked questions

Information

Introduction: fundamentals of laser welding

Abstract:

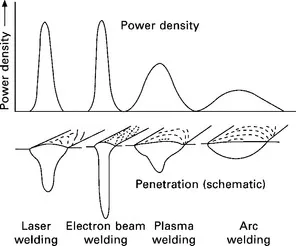

1.1 Characteristics of laser welding

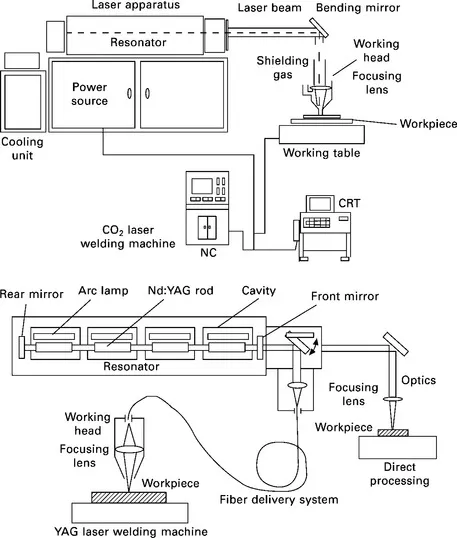

1.2 Lasers for welding

| Types of laser | Laser characteristics |

| CO2 laser | Wavelength: 10.6 μm; far-infrared ray Laser media: CO2-N2-He mixed gas (gas) Average power [CW]: 50 kW (Maximum) (Normal): 1–15 kW |

| Lamp-pumped YAG laser | Wavelength: 1.06 μm; near-infrared ray Laser media: Nd3 +:Y3Al5O12 garnet (solid) Average power [CW]: 10 kW (cascade-type max & fiber-coupling max) (Normal): 50 W–7 kW (Efficiency: 1–4%) |

| Laser diode (LD) | Wavelength: 0.8-1.1 μm; near-infrared ray Laser media: InGaAsP, etc. (solid) Average power [CW]: 10 kW (stack-type max.), 15 kW (fiber-delivery max.) Merits: Compact, and high efficiency (20–60%) |

| LD-pumped solid-state laser | Wavelength: about 1 μm; near-infrared ray Laser media: Nd3 +:Y3Al5O12 garnet (solid), etc. Average power [CW]: 13.5 kW (fiber-coupling max.) [PW]: 6 kW (slab-type max.) |

| Disk laser | Wavelength: 1.03 μm; near-infrared ray Laser media: Yb3 +:YAG or YVO4 (solid), etc. Average power [CW]: 16 kW (cascade-type Max.) Merits: Fiber delivery, high brightness, high efficiency (15–25%) |

| Fiber laser | Wavelength: 1.07 μm; near-infrared ray Laser media: Yb3 +:SiO2 (solid), etc. Average power [CW]: 100 kW (fiber-coupling max.) Merits: Fiber delivery, high brightness, high efficiency (20-30%) |

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Electronic and Optical Materials

- Preface

- Part I: Developments in established laser welding technologies

- Part II: Laser welding technologies for various materials

- Part III: Developments in emerging laser welding technologies

- Part IV: Applications of laser welding

- Index