1.1 Introduction

The transport sector currently accounts for over 30% of the total primary energy consumption in the European Union (EU) and is 98% dependent on fossil fuels. The EU is a net crude oil importer, with an increasing oil dependency ratio (over 80% in 2007, Eurostat). One of the most important energy targets for the EU is thus the reduction of oil use and dependency. A recent EU Directive (2009/28/EC) establishes a 20% target share of renewable energy in primary energy consumption by 2020, with a 10% share of energy from renewable sources for transport. In turn, another EU Directive (2003/96/EC) allows the Member States to have exemptions from or reductions in excise duties so as to promote biofuels and, consequently, there is a growing interest in biofuels in Europe. In this context, biodiesel constitutes a renewable fuel that is almost compatible with commercial diesel engines and has clear environmental benefits relative to diesel fuel.

Biodiesel consists of a mixture of fatty acid methyl esters (FAMEs) obtained from renewable resources, such as vegetable oils and animal fats, by transesterification with methanol in the presence of an acid or basic catalyst. It can be synthesised from a variety of feedstocks, but refined vegetable oils (such as soybean, rapeseed, palm and others) are currently the primary industrial feedstock (first generation biodiesel). The relatively high and unstable prices of these food-grade raw materials, which are linked to the transfer of land from food to energy crops and also to doubts as to whether biofuels are as environmentally friendly as originally thought, constitute a great obstacle for biodiesel production and commercialisation. Likewise, EU Directive (2009/30/CE) establishes, with effect from 1 January 2017, that the greenhouse emission savings from the use of biofuels taken into account for the purpose of 10% shall be at least of 50% (being this value increased up to 60% from 1 January 2018). Annex IV of this Directive indicates that these greenhouse emission savings are in general lower than 50% for the production of biodiesel using conventional edible oils as feedstock, but in contrast, this value is increased to over 80% using waste vegetable or animal oils. Therefore, it is of major importance to study alternative non-edible waste feedstocks for the sustainable production of second generation biodiesel.

Non-edible oils like those derived from jatropha, pongamia, jojoba, and so on are promising feedstocks especially in developing countries where edible oils are in short supply.1,2 Likewise, waste cooking oil (WCO) is considered an economic and increasingly available resource for biodiesel production.3,4 The estimated total waste cooking oil capacity in the EU is 700 000–1 000 000 t/year. Although part of the WCO produced is collected for adequate disposal or treatment, most of the domestic WCO is usually discharged into the environment and is the origin of several problems in wastewater depuration systems. The valorisation of this used oil through the production of biodiesel contributes to increasing its recovery rate from the waste cycle.

Low-grade or waste animal fats can also be used as raw materials for the production of biodiesel.5–7 The production of biodiesel from microalgae, as well as from oleaginous microorganisms, is already considered as interesting feedstock for biodiesel production. Other potential low-cost environmentally friendly sources of biodiesel have been reported. For instance, the solvent extraction of waste coffee grounds yields 10–15% oil depending on the coffee species, which makes this waste a potential candidate for raw material for biodiesel production.8 Municipal sewage sludge (MSS) is also gaining attention as a lipid feedstock for biodiesel production owing to its significant concentration of lipids.9 MSS is plentiful all around the world and its management already poses formidable environmental problems. However, there are still numerous challenges faced in biodiesel production from waste sludge.

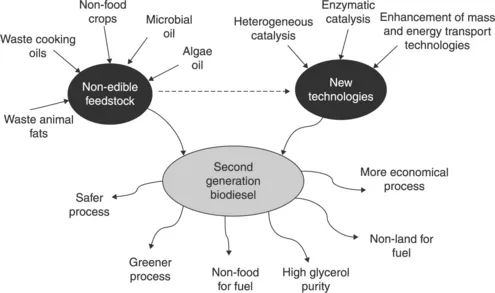

Nevertheless, most technologies for the production of biodiesel using low-quality feedstock are still in their infancy and research efforts are needed in the future. But the development of these technologies in the future will lead to important benefits for the biodiesel industry: less environmental impact, safer processes, higher glycerol purity, reduction of land use and non interference in the food chain (Fig. 1.1).

1.1 Advances in biodiesel production.

In this book, we aim to provide an overview of the different processes and technologies suitable for the production of second generation biodiesel with special emphasis on the development of innovative catalysts as well as new reactor concepts. In the first introductory section, details of the environmental (Chapter 2), political and socio-economic (Chapter 3) implications of the implementation of second generation biodiesel as well as of the different available non-edible feedstocks (Chapter 4) and new trends in quality control and pre-normative standards in biodiesel characterisation (Chapter 5) will be presented. The second part of the book will be focused on an overview of the processes and technologies used for the production of second generation biodiesel (Chapter 6) using low cost non-edible feedstock (waste oils and animal fats, Chapter 7; microbial oil, Chapter 8; microalgae, Chapter 9). The last section of the book will deal with the valorisation of glycerol as by-product of biodiesel production (Chapter 10).

1.2 Processes and technologies for advanced biodiesel production

The current technology for first generation biodiesel production has serious drawbacks. It uses homogenous alkaline catalysts (NaOH, KOH, NaOMe and KOMe) which make it compulsory to separate the spent catalyst from FAME and the glycerol phase by additional washing steps. Hence, although biodiesel is a green product, it is not currently manufactured by a green process.

Likewise, the other difficulty of using alkaline homogenous catalysts is their high sensitivity to free fatty acids (FFAs) and water in the oil source. FFAs react with alkaline catalysts to form soaps, complicating the glycerol separation and reducing FAME yield whereas water in the feedstock results in the hydrolysis of FAME to yield FFAs. The FFA and water content is limited in the feedstock to 0.5 wt% and 0.06 wt%, respectively. Thus, low-quality non-edible feedstock which generally contains a higher content of FFA and water cannot be directly utilised in the existing biodiesel facilities with homogeneous catalysts. Moreover, we must have in mind that the cost of the oil accounts for about 80% of biodiesel production costs.

An important technological challenge in biodiesel production is the design of heterogeneous catalysts.10,11 The use of heterogeneous catalysts would result in simpler, cheaper separation processes, a reduced water effluent load and reduced capital and energy costs. There would be fewer inputs and less waste, as no soap would be formed and the catalyst would not have to be continuously added, would be easier to reuse and could be arranged in fixed-bed reactors. Furthermore, there would be no neutralisation products, so a higher grade of glycerol might be produced without additional purification steps.

The development of basic heterogeneous catalysts for biodiesel production has been widely described in the literature including carbonates and hydrocarbonates of alkaline metals, alkaline metal oxides, alkaline metal hydroxides, anionic resins, basic zeolites, and so on. Some of these catalysts have shown a good catalytic performance even under reaction conditions similar to those of the homogenous catalysts. However, these kinds of catalysts are still far from being used in an industrial application since their evaluation has been carried out in stirred batch reactors but there are few studies in continuous process using packed bed flow reactors. Currently, a unique heterogeneous commercial process is based on the Esterfip-H technology developed by the Institute Français du Petrole (IFP) with a pioneering plant that started up in 2006 with 200 000 metric tonnes per year (France). Several more plants are currently in design and under construction worldwide.

Currently, biodiesel research is focused on exploring new and sustainable solid acid catalysts. Acid catalysts can simultaneously carry out esterification of FFAs and transesterification of triglycerides. Several catalysts have been described so far in the literature: different metal oxides (zirconium, titanium and tin), acid zeolites, sulphonic ion-exchange resin, sulphonated carbon-base catalyst and ...