- 736 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Multifunctional and Nanoreinforced Polymers for Food Packaging

About This Book

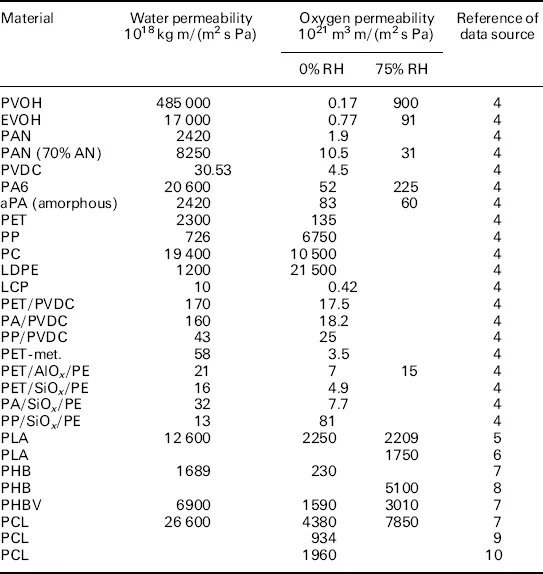

Recent developments in multifunctional and nanoreinforced polymers have provided the opportunity to produce high barrier, active and intelligent food packaging which can help ensure, or even enhance, the quality and safety of packaged foods. Multifunctional and nanoreinforced polymers for food packaging provides a comprehensive review of novel polymers and polymer nanocomposites for use in food packaging.After an introductory chapter, Part one discusses nanofillers for plastics in food packaging. Chapters explore the use of passive and active nanoclays and hidrotalcites, cellulose nanofillers and electrospun nanofibers and nanocapsules. Part two investigates high barrier plastics for food packaging. Chapters assess the transport and high barrier properties of food packaging polymers such as ethylene-norbornene copolymers and advanced single-site polyolefins, nylon-MXD6 resins and ethylene-vinyl alcohol copolymers before going on to explore recent advances in various plastic packaging technologies such as modified atmosphere packaging (MAP), nanoscale inorganic coatings and functional barriers against migration. Part three reviews active and bioactive plastics in food packaging. Chapters investigate silver-based antimicrobial polymers, the incorporation of antimicrobial/antioxidant natural extracts into polymeric films, and biaoctive food packaging strategies. Part four examines nanotechnology in sustainable plastics with chapters examining the food packaging applications of polylactic acid (PLA) nanocomposites, polyhydroxyalkanoates (PHAs), starch-based polymers, chitosan and carragenan polysaccharides and protein-based resins for packaging gluten (WG)-based materials. The final chapter presents the safety and regulatory aspects of plastics as food packaging materials.With its distinguished editor and international team of expert contributors Multifunctional and nanoreinforced polymers for food packaging proves a valuable resource for researchers in packaging in the food industry and polymer scientists interested in multifunctional and nanoreinforced materials.

- Provides a comprehensive review of novel polymers and polymer nanocomposites for use in food packaging

- Discusses nanofillers for plastics in food packaging including the use of passive and active nanoclays and hidrotalcites and electrospun nanofibers

- Investigates high barrier plastics for food packaging assessing recent advances in various plastic packaging technologies such as modified atmosphere packaging (MAP)

Frequently asked questions

Information

Multifunctional and nanoreinforced polymers for food packaging

Abstract:

1.1 Introduction

1.1.1 High barrier concept

1.1.2 Functional packaging

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Preface

- Chapter 1: Multifunctional and nanoreinforced polymers for food packaging

- Part I: Nanofillers for plastics in food packaging

- Part II: High barrier plastics for food packaging

- Part III: Active and bioactive plastics

- Part IV: Nanotechnology in sustainable plastics for food packaging

- Index