Human Fatigue Risk Management

Improving Safety in the Chemical Processing Industry

- 282 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Human Fatigue Risk Management

Improving Safety in the Chemical Processing Industry

About This Book

Human Fatigue Risk Management: Improving Safety in the Chemical Processing Industry teaches users everything they need to know to mitigate the risk of fatigued workers in a plant or refinery. As human fatigue has been directly linked to several major disasters, the book explores the API RP 755 guidelines that were released to reduce these types of incidents. This book will help users follow API RP 755 and/or implement a fatigue risk management system in their organization.

Susan Murray, a recognized expert in the field of sleep deprivation and its relation to high hazard industries, has written this book to be useful for HSE managers, plant and project managers, occupational safety professionals, and engineers and managers in the chemical processing industry. As scheduling of shifts is an important factor in reducing fatigue and accident rates, users will learn the benefits of more frequent staff rotation and how to implement an ideal scheduling plan.

The book goes beyond API RP 755, offering more detailed understanding of why certain measures for managing fatigue are beneficial to a company, including examples of how theory can be put into practice. It is a simple, digestible book for managers who are interested in addressing human factor issues at their workplace in order to raise safety standards.

- Covers sleep, sleep disorders, and the consequences of fatigue as related to high-hazard industries

- Helps improve safety standards at the plant level

- Provides information on how to comply with API RP 755 and related OSHA 29CFR1910 articles

- Relates fatigue and human performance to accidents, helping readers make a case for implementing a human fatigue risk management policy, which, in turn, prevents loss of property and life

Frequently asked questions

Information

The consequences of fatigue in the process industries

Abstract

Keywords

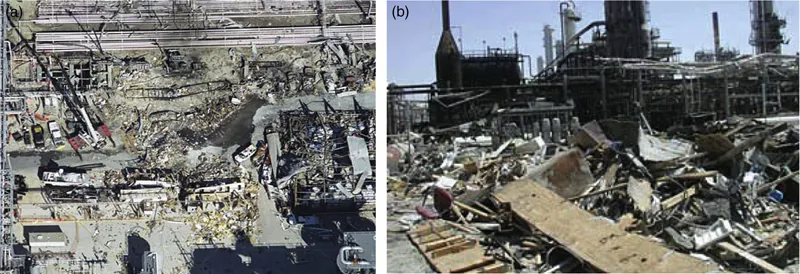

1.1. BP Texas City

(a) From the CSB website. (b) From the final report. (Sources: Part a: http://www.csb.gov/bp-texas-city-investigative-photos/. Part b: http://www.csb.gov/bp-america-refinery-explosion/.)

1.2. Human factors and the BP Texas City accident

Table of contents

- Cover

- Title page

- Table of Contents

- Copyright

- About the Authors

- Foreword

- Acknowledgments

- Chapter 1: The consequences of fatigue in the process industries

- Chapter 2: Basics of sleep biology

- Chapter 3: Circadian rhythms and sleep–circadian interactions

- Chapter 4: Sleep hygiene recommendations

- Chapter 5: Sleep disorders

- Chapter 6: Fatigue and human performance

- Chapter 7: Fatigue and accidents

- Chapter 8: Fatigue-related regulations and guidelines

- Chapter 9: Fatigue counter measures

- Chapter 10: Work shifts

- Chapter 11: Work environment

- Chapter 12: Work task design

- Chapter 13: Employee training

- Chapter 14: Naps

- Chapter 15: Compounds that alter sleep and wakefulness

- Chapter 16: Creating a fatigue risk management system (FRMS)

- Chapter 17: Accident investigation

- Index