- 1,088 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Diesel Engine System Design

About this book

Diesel Engine System Design links everything diesel engineers need to know about engine performance and system design in order for them to master all the essential topics quickly and to solve practical design problems. Based on the author's unique experience in the field, it enables engineers to come up with an appropriate specification at an early stage in the product development cycle.

- Links everything diesel engineers need to know about engine performance and system design featuring essential topics and techniques to solve practical design problems

- Focuses on engine performance and system integration including important approaches for modelling and analysis

- Explores fundamental concepts and generic techniques in diesel engine system design incorporating durability, reliability and optimization theories

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Fundamental concepts in diesel engine system design – analytical design process, durability, reliability, and optimization

1

The analytical design process and diesel engine system design

Abstract:

Diesel engine system design (DESD) is an important and leading function in the design and development of modern low-emissions EGR diesel engines. It creates a paradigm shift in how engine design is carried out. It leads and integrates the designs from the system level to the component level by producing high-quality system design specifications with advanced analytical simulation tools. This chapter introduces the fundamental concepts in diesel engine system design and provides an overview on the theory and approaches in this emerging technical field. The central theme is how to design a good engine system performance specification at an early stage of the product development cycle. The chapter employs a systems engineering approach and applies the concepts of reliability and robust engineering to diesel engine system design to address the optimization topics encountered in design for target, design for variability, and design for reliability. An attribute-driven system design process is developed for advanced analytical engine design from the system level to the subsystem/component level in order to coordinate different design attributes and subsystems. Four system design attributes – performance, durability, packaging, and cost – are elaborated. The chapter also addresses competitive benchmarking analysis. By focusing on engine performance and system integration (EPSI), the technical areas, theoretical foundation, and tools in diesel engine system design are introduced.

Key words

diesel engine system design (DESD)

engine performance and system integration (EPSI)

systems engineering

robust engineering

reliability

variability

design target

design attributes

performance

durability

packaging

cost

competitive benchmarking

engine cycle simulation

exhaust gas recirculation (EGR)

1.1 Characteristics and challenges of automotive diesel engine design

1.1.1 Classification of diesel engines

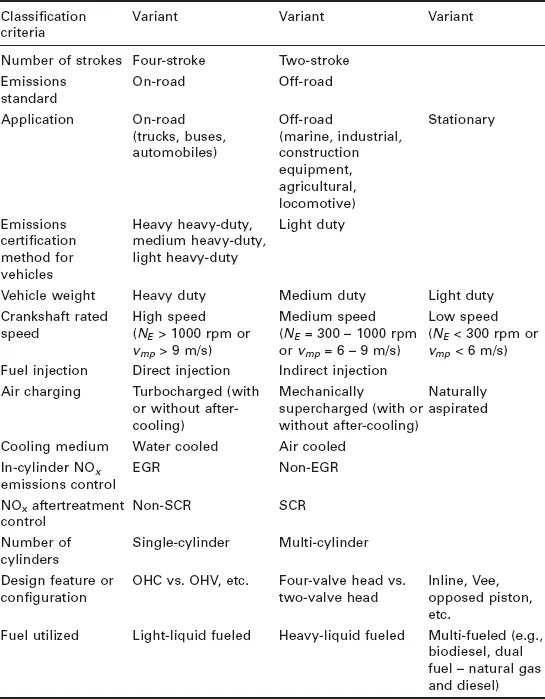

A diesel engine is a type of compression-ignition engine using diesel fuel. Diesel engines can be classified into various categories (Table 1.1). Understanding the differences and the unique characteristics of each category of diesel engines is important for diesel engine system design. According to the number of crankshaft revolutions per working cycle, diesel engines are classified as four-stroke engines (two revolutions per cycle) and two-stroke engines (one revolution per cycle). According to emissions standards and engine applications, diesel engines are classified as on-road, off-road and stationary. The on-road applications include trucks, buses and automobiles. The off-road applications include marine, industrial (e.g., diesel for compressors), construction equipment, agricultural (e.g., tractors), and locomotive. For emissions standards, the reader is referred to the websites of the US EPA at www.epa.gov, DieselNet at www.DieselNet.com, and Appendix A in Rakopoulos and Giakoumis (2009). According to emissions certification methods for on-road applications, diesel engines are classified as heavy-duty and light-duty (Table 1.2). The American Automotive Manufacturers Association (AAMA) classifies trucks into three categories (heavy-duty, medium-duty, and light-duty) and eight classes by vehicle weight (Table 1.3). Heavy-duty applications include trucks, buses, certain off-road vehicles, marine engines, generator sets (gensets), industrial power plants, etc. Light-duty applications include passenger cars, sport-utility vehicles and light trucks (e.g., some pickup trucks).

Table 1.1

Diesel engine classification

Table 1.2

EPA vehicle weight classification

| Vehicle weight | Classification | Emissions certification |

| < 8500 lbs GVW | Light-duty (LD) | Vehicle chassis |

| > 8500 lbs GVW | Light heavy-duty: 110,000 miles of useful life for compliance with the legislated emissions standards | Engine dynamometer |

| > 8500 lbs GVW | Medium heavy-duty: 185,000 miles of useful life | Engine dynamometer |

| > 8500 lbs GVW | Heavy heavy-duty: 290,000 miles of useful life | Engine dynamometer |

Table 1.3

AAMA vehicle weight classification

| Vehicle weight | Classification | |

| Class 1 | < 6000 lbs GVW | Light-duty (LD) trucks |

| Class 2 | 6001–10,000 lbs GVW | Light-duty (LD) trucks |

| Class 3 | 10,001–14,000 lbs GVW | Light-duty (LD) trucks |

| Class 4 | 14,001–16,000 lbs GVW | Medium-duty (MD) trucks |

| Class 5 | 16,001–19,500 lbs GVW | Medium-duty (MD) trucks |

| Class 6 | 19,501–26,000 lbs GVW | Medium-duty (MD) trucks |

| Class 7 | 26,001–33,000 lbs GVW | Heavy-duty (HD) trucks |

| Class 8 | > 33,000 lbs GVW | Heavy-duty (HD) trucks |

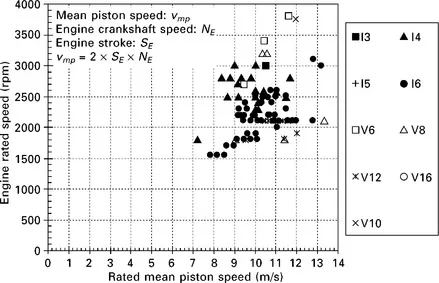

Diesel engines are also classified as low-speed (rated speed of crankshaft rotation slower than approximately 300 rpm), medium-speed (300–1000 rpm) and high-speed (faster than 1000 rpm). They can be also classified by using the mean piston speed at the rated speed. For example, a mean piston speed slower than 6 m/s is regarded as low-speed, 6–9 m/s as medium-speed, and faster than 9 m/s as high-speed. The engine crankshaft rotational speed versus mean piston speed of many high-speed diesel engines in North America is shown in Fig. 1.1. It is observed that there is a large variability in the data due to the differences in engine stroke. There is no clear design trend in the correlation between these two speeds. The above classifications according to the speeds are only approximate.

1.1 North American HD and LD high-speed diesel engines.

According to different fuel injection methods, diesel engines are classified as indirect injection and direct injection. By air charging method, diesel engines are classified as naturally aspirated, mechanically supercharged and aerodynamically turbocharged engines. By cooling medium, diesel engines are divided into water-cooled and air-cooled. Most modern diesel engines are direct-injection, turbocharged (with inter-cooling or also known as after-cooling or charge air cooling) and water-cooled engines. According to in-cylinder NOx emissions control and NOx aftertreatment technology, diesel engines are classified into EGR (exhaust gas recirculation) engine, non-EGR engine, SCR (selective catalytic reduction) engine and non-SCR engine. Moreover, by different fuels utilized or fuel compatibility, diesel engines are classified as light-liquid-fueled, heavy-liquid-fueled or multi-fueled engines. The main body of this book focuses on four-stroke on-road heavy-duty turbocharged EGR diesel engines for automotive vehicle applications.

1.1.2 Comparison between diesel engines and gasoline engines

Understanding the fundamental characteristics of diesel engines is very important for engine system design and powertrain technology assessment. Compared to gasoline engines, diesel engines have the following advantages:

• Low fuel consumption and low CO2 emissions. The high compression ratio used in diesel engines generally results in high thermodynamic cycle efficiency although mechanical friction may increase with peak cylinder pressure. Diesel engines usually use unthrottled operation so that the pumping loss can be lower.

• High power. Diesel combustion does not have the severe limitation of auto-ignition as seen in gasoline engines so that diesel engines can use a large cylinder diameter and tolerate a high level of turbocharging in order to produce high power.

• High torque at low speeds and better drivability. Diesel combustion can tolerate a high level of turbocharging so that they can burn more fuel to match the available charge air to produce higher torque than gasoline engines.

• Low carbon monoxide (CO) and hydrocarbons (HC) due to the high air–fuel ratio employed in diesel combustion.

It should be noted that in modern diesel engines with high EGR for NOx control, the traditional advantage of unthrottled operation may be lost due to the need to drive EGR flow by closing an intake throttle valve at certain operating conditions, if the system is not carefully designed. Moreover, high EGR rate leads to high peak cylinder pressure due to the increased intake manifold boost pressure required. Such a high cylinder pressure may result in a reduction in the allowable air–fuel ratio or engine compression ratio. The superior fuel ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Nomenclature

- List of abbreviations and acronyms

- Dedication

- About the author

- Preface

- Part I: Fundamental concepts in diesel engine system design – analytical design process, durability, reliability, and optimization

- Part II: Engine thermodynamic cycle and vehicle powertrain performance and emissions in diesel engine system design

- Part III: Dynamics, friction, and noise, vibration and harshness (NVH) in diesel engine system design

- Part IV: Heat rejection, air system, engine controls, and system integration in diesel engine system design

- Appendix: Statistics summary for probability analysis

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Diesel Engine System Design by Qianfan Xin in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mechanical Engineering. We have over one million books available in our catalogue for you to explore.