1.1 Introduction

With today’s concerns about energy and environmental impact, the natural gas combined cycle power plant (CCPP) plays a leading role in the power complexes of the world. CCPPs are the most efficient power plants operating on the power grids throughout the world with an efficiency ranging between 45% and 57%. These power plants come in all sizes. In this chapter we will be emphasizing the larger plants ranging in size from 60 to 1500 MW. These combined cycle plants have as their core the gas turbine, which acts as the topping cycle, and the steam turbine, which acts as the bottoming cycle. Between the gas turbine and the steam turbine is a waste heat recovery steam generator (HRSG), which takes the heat from the exhaust of the gas turbine and generates high-pressure (HP) steam for the steam turbine.

The natural gas CCPP is attractive to the power industry because it has the following major characteristics:

1. These plants will displace coal in the power generation sector by 2050, under a model scenario where industrialized nations reduce CO2 emissions by 2050 through carbon emission pricing. Large emerging economies such as Brazil, China, and India will reduce CO2 emissions by 2070.

2. The plant has efficiency between 50% and 60%, the highest efficiency in the marketplace for a power plant type.

3. The steam turbine plant fired by coal or oil is the most widely used plant in the world and has an efficiency of about 30–35%.

4. The plant has a very compact footprint compared with other major types of power plants, and thus is environmentally friendly to the ecosystem.

5. The construction time of a major CCPP of 200 MW and above could be less than 24 months.

6. The emissions of unburnt hydrocarbons (UHCs), CO and oxides of nitrogen (NOx) (less than 9 ppm) are the lowest of any thermal power plant.

7. For plants larger than 200 MW, the cost of the plant ranges between $450 and $650/kW; for plants below 200 and 5 MW, the cost of the plant can vary, respectively, from $650/kW to about $1200/kW.

CCPPs associated with electrical power plants use waste heat from the prime mover for the production of steam and consequently the steam is used in a steam turbine for the production of additional power. This is usually a combination of the Brayton cycle (gas turbine) as the topping cycle, and the Rankine cycle (steam turbine) as the bottoming cycle. However, technically the term ‘combined cycle’ can be used for any combination of two or more cycles. Many small plants use the diesel cycle as the topping cycle with the Rankine cycle as the bottoming cycle; there is a small number of plants that use the Brayton cycle as both the topping and the bottoming cycles. Figure 1.1 shows a large CCPP.

1.1 A typical combined cycle facility showing two plants of four gas turbines each.

The fossil power plants of the 1990s and the early part of the new millennium are the CCPPs, with the gas turbine being the centerpiece of the plant. It is estimated that between 1997 and 2010 an additional 147.7 GW of combined cycle power has been built. These plants have replaced the large steam turbine plants that were the main fossil power plants through most of the 1900s. The CCPP is not new in concept, since some have been in operation since the 1950s. These plants came into their own with the new high-capacity and high-efficiency gas turbines, with their new materials and advanced combustion systems.

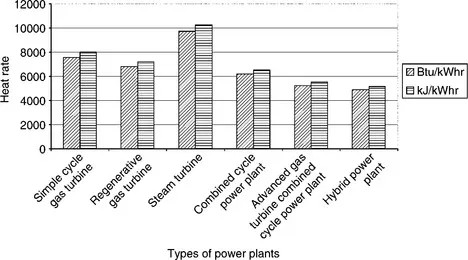

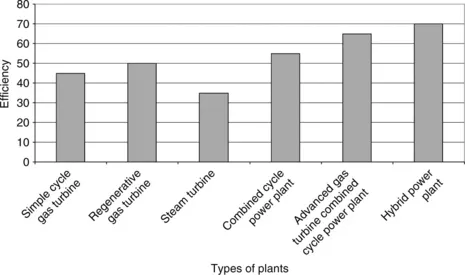

The new energy conversion marketplace will find many novel concepts in CCPPs. Figure 1.2 shows the heat rates of present and future plants, and Fig. 1.3 shows their efficiencies. The plants referenced are the simple cycle gas turbine (SCGT) plants with firing temperatures of 2400 °F (1315 °C); recuperative gas turbine (RGT) plants, where the exhaust gases from the turbine are used to heat the incoming air to the combustion chamber; the steam turbine plants; the CCPPs; the advanced combined cycle power plants (ACCPs), such as CCPPs using advanced gas turbine cycles; and finally the hybrid power plants (HPPs), combined cycle plants with fuel cells.

1.2 Typical heat rates of various types of plants.

1.3 Typical efficiencies of various types of plants.

The steam turbine power plants have an efficiency of about 30% to 35% compared with CCPPs, which have an efficiency from 47% to 58%. Newer gas turbine technology will make combined cycle efficiencies to range between 60% and 65%. As a rule of thumb, a 1% increase in efficiency could mean a saving of 3.3% in capital expenditure for the same size plant. However, one must be careful that the increase in efficiency does not lead to a decrease in availability. From 1996 to 2000 we have seen a growth in efficiency of about 10% and a loss in availability of about 10%. This trend must be turned around since many analyses show that a 1% drop in availability needs an increase in efficiency of about 2–3% to offset the loss.

The time taken to design, construct and commission a steam plant from conception to production is about 42–60 months as compared to 22–36 months for a natural gas CCPP. The actual construction time is about 18 months, while environmental permits in many cases take 12 months and engineering 6–12 months. The time taken to bring the plant on line affects the economics of the plant: the longer the capital is employed without return, the greater is the interest, insurance and taxes that accumulate.

CCPPs and cogeneration plants are very similar in their thermodynamic properties. Cogeneration is the production of two or more forms of energy from a single plant. The most common application of the term is for the production of electrical power and steam for use in process applications. This does not mean that other types of cogeneration plants are not being designed and used. Cogeneration plants are used to produce power and use the direct exhaust gases from the prime movers for preheating air in furnaces or in absorption cooling systems, or for heating various types of fluids in different process applications. During the timeframe 1996–2006, cogeneration plants accounted for 3% of the new power being generated worldwide, amounting to 19.6 GW of electrical power.

A typical cogeneration plant uses the waste gases from the gas turbine to produce steam in an HRSG or a waste heat boiler (WHB); these terms are often used interchangeably i...