This is a test

- 628 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Book details

Book preview

Table of contents

Citations

About This Book

This book provides an overview of the fabrication methods for anti-abrasive nanocoatings. The connections among fabrication parameters, the characteristics of nanocoatings and the resulting properties (i.e. nanohardness, toughness, wear rate, load-bearing ability, friction coefficient, and scratch resistance) are discussed. Size-affected mechanical properties of nanocoatings are examined, including their uses. Anti-abrasive nanocoatings, including metallic-, ceramic-, and polymeric-based layers, as well as different kinds of nanostructures, such as multi-layered nanocomposites and thin films, are reviewed.

- Provides a comprehensive overview of the fabrication methods for anti-abrasive nanocoatings

- Discusses the connections among fabrication parameters, the characteristics of nanocoatings and the resulting properties

- Reviews advantages and drawbacks of fabrication methods for anti-abrasive nanocoatings and clarifies the place of these nanocoatings in the world of nanotechnology

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Anti-Abrasive Nanocoatings by M Aliofkhazraei in PDF and/or ePUB format, as well as other popular books in Physical Sciences & Physics. We have over one million books available in our catalogue for you to explore.

Information

Part One

Outline

1

Wear, friction and prevention of tribo-surfaces by coatings/nanocoatings

Sunil Mohan and Anita Mohan, Indian Institute of Technology (BHU), Varanasi, India

This chapter gives an broad up-to-date overview of wear, friction and prevention of tribo-surfaces. Tribology is the science and technology of wear, friction and lubrication. It plays an important role in design and performance of all mechanical systems. The basic mechanism of friction involves its physical, chemical and material properties. It is a situation-based or system-based property. The mechanisms involved at microscopic level include adhesive forces between mating surfaces, mechanical interactions of asperities, the ploughing of one surface due to harder asperities of the other, deformation of surfaces or fracture in oxide film and/or the introduction of a third body due to debris as well as environmental effects.

Wear is a perennial phenomenon of surface damage in contacting bodies, which may be solid–solid, solid–liquid or solid–air. Wear in solid–solid contacts takes place through two basic phenomena: adhesion and abrasion. There are a number of factors that affect the rate at which the contacting surfaces wear off. It is not possible to completely eliminate losses due to wear and friction, but they can be minimised.

Keywords

friction; nanocoatings; surface treatments; tribology; wear

1.1 Introduction

Tribology is at the forefront of modern research of practical importance. It deals with the science and technology of wear, friction and lubrication, which has applications in our day-to-day life in different ways. In prehistoric times, men created fire using frictional heating of stones. With time our knowledge has increased immensely. There are numerous examples of tribology in our day-to-day life. Since the scope of this chapter is limited, emphasis will be given to the tribology of mechanical systems exposed to wear and friction during solid–solid contact (Lubrication Engineering Working Group, 1966).

Leonardo da Vinci was the first to postulate the concept of friction in 1519, and this was further advanced by French physicist Guillaume Amontons by the end of the seventeenth century. It was, however, elaborated by C.A. Coulomb, in 1785, who distinguished between static and kinetic friction (Szeri, 1998) (cf. Table 1.1).

Table 1.1

Progression in friction concept

| Progression in concept | Date |

| Leonardo da Vinci was the first to introduce the concept of friction | 1519 |

| Guillaume Amontons further clarified the concept | Late seventeenth century |

| C.A. Coulomb distinguished conceptualized static and kinetic friction | 1785 |

| Bowden and Tabor did extensive work on the mechanism of friction and provided major evidence of adhesion theory, including plastic deformation of asperities | Mid-twentieth century |

| Further additions in the coefficient of friction were made by N. P. Suh and Larsen-Basse | End of the twentieth century |

In general, wear refers to the damage to the surface or loss of material from one or both solid bodies in contact. Such situations arise when surfaces are in sliding or rolling contact. Adhesive, abrasive, fatigue and corrosion are the most common types of wear in tribological applications. Wear is a perennial phenomenon of surface damage in contacting bodies, which may be solid–solid, solid–liquid or solid–air. Whatever the system may be we cannot get away from its complexity; as stated by (Rigney et al., 1984, p. 195): ‘wear is just like a jigsaw puzzle in which pieces fit together here and there but the overall pattern is far from clear’. Wear process in solid–solid contact is very complex. It should be noted here that with the available data, equations generalization of the process is still elusive. Wear in solid–solid contacts takes place because of adhesion and abrasion. The rate at which the contacting surfaces wear off mainly depends on various characteristics of each surface, applied load, sliding velocity, distance slid, temperature and environmental factors.

Wear and friction lead to tremendous losses in the form of energy and material. If we combine both, they amount to heavy financial loss. For example an expert estimate shows that in 1978 in US only the energy loss was about 4.22×106 T Joule, which amounted to $20 billion (Szeri, 1998). Even after more than three decades, it is not possible to eliminate losses completely because of wear and friction. However, this can be minimized to a large extent by proper materials choice, altering material properties and providing suitable surface treatment or coatings/nanocoatings.

1.2 Friction of materials

The basic mechanism of friction depends on various factors such as physical, chemical and materials properties. Over the years, several mechanisms have been proposed with modifications. However, the basic mechanism remains the same. In actuality, it is situation-based or system-based property. The mechanisms involved at microscopic level are adhesive forces between mating surfaces, mechanical interactions of asperities, the ploughing of one surface due to the harder asperities of other surface, deformation of surfaces or fracture in oxide film and/or introduction of a third body as a result of debris or environmental effects. Various attempts have been made to explain friction (cf. Bowden and Tabor, 1964; Dowson, 1979; Ludema, 1987).

Bowden and Tabor (1964) did extensive research into friction. Although adhesion is the main cause of friction, adhesion and deformation both contribute to the energy dissipation in friction. Bowden and Tabor (1964) provided major evidence supporting adhesion theory including plastic deformation of asperities. They proved experimentally that the mechanical properties of contacting surfaces play an important role. As a result of their seminal contribution in this field, adhesion theory is attributed to Bowden and Tabor.

Bowden and Tabor (1964) assumed that interacting asperities undergo deformation up to plastic flow regime and reach pressure equal to the indentation hardness of the material. In such case, the real area of contact (Ar) is determined as:

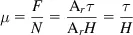

It is further assumed that friction is due to shearing of bonds during sliding. This means that the coefficient of friction (µ) is given by:

where N is normal load in newton, H is flow hardness in N/m2 and τ is shear stress.

This expression satisfies both of the Amontons laws in which both load and contact area are eliminated. Hardness is almost three times the flow stress (σy) of the material and shear stress (τ) is almost equal to 0.5 to 0.6σy. Therefore, the universal value of coefficient of friction should be 0.17 to 0.2 (Larsen-Basse, 1992). As a matter of fact, it is true for clean pure metals but values are much higher in a vacuum when there is no protective layer. In a further study, Bowden and Tabor (1950) took three pairs of sliders of a material against three different flat surfaces (cf. Figure 1.1) to see the effect of a contacting surface with a different shearing force on the coefficient. The results are summarized in Table 1.2...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- List of figures

- List of tables

- About the editor

- About the contributors

- Preface

- Part One

- Part Two

- Part Three

- Index