- 128 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Fatigue in Railway Infrastructure

About this book

Fatigue is a major issue affecting safety and quality of service in the railway industry. This book reviews key aspects of this important subject. It begins by providing an overview of the subject, discussing fatigue at the wheel-rail interface and in other aspects of infrastructure. It then considers fatigue in railway and tramway track, looking at causes of potential failure in such areas as rails and fixings as well as sleepers. It also reviews failure points in structures such as embankments and cuttings. The book analyses fatigue in railway bridges, looking in particular at masonry arch bridges as well as metal and concrete bridges. Two final chapters review safety and reliability issues affecting escalators and lifts.Fatigue in railway infrastructure is a helpful reference for those in the railway industry responsible for infrastructure maintenance as well as those researching this important subject.

- Provides a concise review of fatigue in the railway infrastructure

- Examines the causes of potential failure in rails, fixings and sleepers

- Analyses fatigue in railway bridges including masonry arch, metal and concrete structures

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Fatigue and the railways: an overview

R.A. Smith Imperial College London, UK

Abstract

This chapter provides an overview of fatigue issues affecting railways. It starts by considering fatigue at the wheel–rail interface, particularly the effect of dynamic loads on rails, bearings, axles, suspension and other components. It then reviews fatigue issues in vehicles such as body shells, engines, couplings and internal components. Finally, it considers fatigue in infrastructure such as bridges and signalling systems.

Key words

fatigue in railways

wheel–rail interface

dynamic loads

rail vehicles

rail infrastructure

1.1 Introduction

Study of the type of material failure we now call fatigue originated from problems on the railways about 200 years ago. Fatigue still causes failures in many kinds of components, in many different industries, and failures still occur in railways. In recent years, two accidents caused by fatigue had particularly serious repercussions. On 3 June 1998, a German Intercity Express (ICE) was derailed after a wheel failed and then subsequently caught in a set of points, causing a carriage to strike the support of an over-bridge. The bridge collapsed and several carriages piled up in the debris of the bridge; 101 people were killed. A recent paper gives some background, but is incomplete in detail (Esslinger et al., 2004). On 17 October 2000, a British train derailed at Hatfield, just north of London, killing four passengers. The immediate cause of the derailment was identified as a broken rail, and a subsequent examination of the UK network led to the discovery of more than 2000 sites containing potentially dangerous cracks. Severe speed restrictions were imposed while repair and replacement of track took place over a period of many months. In the long history of Britain’s railways, no previous accident had caused such widespread public anger, managerial panic, disruption and eventual political crisis (Jack, 2001; Murray, 2001; Wolmar, 2001). The railway system had been privatised between 1996 and 1998, by fragmenting it into more than 125 companies and separating operations from infrastructure, the latter being a common feature of several other privatisations in other countries. As a consequence of the Hatfield accident and its aftermath, Railtrack, the UK infrastructure company, was taken into receivership in October 2001 and was subsequently reformed as a ‘not-for-profit’ company, Network Rail. More recently, changes in the organisational structure of the railway designed to reduce fragmentation have been announced (Anon., 2004).

At first sight it seems surprising that, despite its long history, catastrophic fatigue failures still occur. But these well-publicised accidents are only the tip of the iceberg. The consequences of a failure depend on a chance chain of events occurring after the failure. In most cases, usually by good fortune, the consequences are not so severe, but much can still be learnt from all incidents, so that, by investigation and good reporting, future similar occurrences may be reduced.

It is the purpose of this chapter to provide a broad overview of fatigue failures in railways and to make some suggestions about the most effective ways of reducing their incidence. The fatigue process itself will not be discussed in detail: many excellent books and reviews are readily available (Suresh, 1998; Schijve, 2001, 2003).

It is probably worth noting that the term fatigue here is used throughout to mean the fatigue of materials and not human fatigue due to tiredness. This latter kind of fatigue also has a long history of causing accidents on railways!

1.2 Fatigue and railways

Railways are characterised by the contact between the vehicle’s wheels and the rails, the guidance system. The major benefit of railways as a transportation system stems from this key feature. Because this contact is very stiff, the rolling resistance is low, so that heavy loads can be hauled with comparatively small tractive effort. Indeed, much of the operation of a railway system is determined by the peculiarities of the wheel–rail interface. Acceleration and braking are determined by adhesion, stopping distances define the characteristics of the signalling and control system and the latter defines the capacity of the system. It will be noted that both the major failures referred to above were at the wheel–rail interface, and it is failures at this location that are particular to railways. There are, however, a large number of other fatigue failures that concern the railways, but they are not necessarily railway specific. Table 1.1 attempts to summarise most of the major areas of concern and defines the order in which the discussion that forms the remainder of this chapter is structured.

Table 1.1

Significant areas of fatigue in railways

| Adjacent to wheel–rail interface | Wheels Rails Rail welds |

| Affected by forces generated at the wheel–rail interface | Bearings Axles Gearboxes Drive shafts Bogies Springs and suspension components Brake components Rail fastenings and supports Track foundation |

| Vehicles | Engine or motor components Body shells Couplings Internal components and fittings |

| Infrastructure | Bridges Signals Electrical supply components |

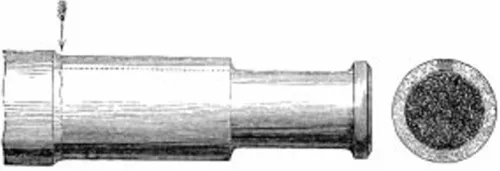

It should be recognised that railway equipment operates in a hostile environment, which is often dirty and wet. Perhaps surprisingly, despite long experience, the loads and stresses to which equipment is subjected are often inadequately defined. This is particularly true of dynamically induced loads of which more is said later. Rolling stock is designed to last for between 30 and 40 years but is often used for much longer. Major infrastructure can last for considerably more than 100 years. These very long service lives mean that the obvious principal design requirement against fatigue failure is that stress ranges should be below the fatigue limit. This apparently simple requirement is not as easy to apply as may be imagined, partly because the loading spectrum can contain many larger load excursions superimposed on a baseline of constant amplitude loading, and partly because of competing deterioration mechanisms such as wear and corrosion which can erode the original design margin. The fatigue limit concept was determined from extensive experiments conducted by the German railway engineer Wöhler, in a study of the fatigue of axles, Fig. 1.1 (Wöhler, 1858–1871). Despite its long use, there is growing evidence that for lives longer than the conventional 106–107 cycles at which the fatigue limit is determined, the safe stress range continues to be eroded down to 109 cycles and more, that is, at the very long lives typical of that required of axles and wheels (Stanzel-Tschegg, 2002).

1.1 A typical axle failure of the 1840s (shown by arrow) leading to the birth of the fatigue problem.

Although, in general, it may be said that most fatigue problems have been satisfactorily solved, the need for safety means that components must be subjected to expensive inspections in order to guard against a small number of possible failures. These inspections are not always reliable in identifying possible deterioration, and the dismantling necessary to achieve access can often introduce inadvertent damage.

The long service lives of railway equipment mean that the ‘technological window’ for railways is particularly wide. New technologies take a long time to be implemented across the whole system and must work side by side with existing equipment during the substitution period. For example, a new improved rail steel, however great its advantages, will not be in use system-wide for at least 50–60 years. Again, improved information technology, easily applied to new-build vehicles, may only be applicable to existing vehicles by expensive retrofits. By contrast, the automobile industry renews itself almost completely in a 10-year life cycle. These issues will be amplified by discussing the various areas of fatigue shown in Table 1.1.

1.3 Fatigue at the wheel–rail interface

A single contact patch between the wheel and the rail is typically the size of a small coin: a long train is completely supported over a total area no larger than that of a compact disc. Clearly, the pressures at the key interface are very high, considerably in excess of the normal yield stress of the material. A complex series of events takes place with repeated passages of a wheel over a rail. The material in the immediate vicinity of the contact work-hardens and deforms until its ‘ductility is exhausted’1 and a series of small cracks forms. Ideally, if the wear rate of the railhead or wheel equals or exceeds the rate at which cracks are initiated, then the cracks are ‘rubbed out’ before they can develop. However, if the crack development rate exceeds the wear rate, the cracks propagate deeper into the material, driven by the contact stresses. As the contact stresses diminish with depth into the material, the bulk stresses in the interior of the wheel or rail take over as the drivers of the crack. The possibility therefore exists of non-propagating cracks, if ‘handshakes’ fail to happen in the zones of transfer in the sequence of the change-over of the governing stress from the surface stress to the contact zone stress to the bulk stress. This type of behaviour is paralleled in other fatigue situations when cracks initiate in high surface stress fields at, for example, sharp geometric notches, fretting patches and thermally loaded surfaces. In both wheels and rails, cracks can turn back up towards the surface, leading to the formation of a detached flake (spalling).

1.3.1 Fatigue of wheels

This kind of spalling damage is relatively common on railway wheels. It leads to poor running conditions and high dynamic impact loads. In most cases this damage, if caught in its early stages, can be removed by re-turning the tread of the wheel. Similarly, out-of-roundness (polygonisation) or wheel flats, caused by sliding, can be machined out before damage becomes too widespread. Turning is used in the first instance to re-profile the wheel, in order to improve contact patch conditions, which are particularly sensitive to the local geometries of the wheel and rail at the site of the contact. In the past, wheels were usually manufactured by shrink fitting a tyre onto a hub. The famous ‘wheel tappers’, whom older readers may remember, were listening principally for loose tyres rather than for cracks as is often supposed. Modern practice is to make wheels of a monobloc construction, with a relatively thin web, curved in the plane of the wheel to give lateral strength through geometry. Failures in the web are rare. However, despite all our knowledge of stress concentrations, a recent wheel fracture on a high-speed train initiated at a hole that had been drilled into the web of the wheel in order to attach a balance weight. The wheel disintegrated, but the train was fortunately able to come to a halt without causing any casualties (a good example of fate being kind, and the failure not unleashing a catastrophic series of events). This obviously dangerous method of balancing has been ceased. The wheels are now balanced by eccentric machining of the interior underside of the rim in a manner which achieves balance by removing a small crescent-shaped piece of material smoothly blended into the profile, thus avoiding any stress concentrating discontinuities.

The much-publicised accident to the German ICE train in 1998, which resulted in more than 100 fatalities,...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Contributor contact details

- Preface

- 1: Fatigue and the railways: an overview

- 2: Fatigue in railway and tramway track

- 3: Fatigue in railway bridges

- 4: Safety and reliability issues affecting escalators and moving walkways in railway stations

- 5: Design, safety and reliability of lifts in railway stations

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Fatigue in Railway Infrastructure by Mark Robinson,Ajay Kapoor in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Civil Engineering. We have over one million books available in our catalogue for you to explore.