- 392 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Computer Technology for Textiles and Apparel

About this book

Computer technology has transformed textiles from their design through to their manufacture and has contributed to significant advances in the textile industry. Computer technology for textiles and apparel provides an overview of these innovative developments for a wide range of applications, covering topics including structure and defect analysis, modelling and simulation, and apparel design.The book is divided into three parts. Part one provides a review of different computer-based technologies suitable for textile materials, and includes chapters on computer technology for yarn and fabric structure analysis, defect analysis and measurement. Chapters in part two discuss modelling and simulation principles of fibres, yarns, textiles and garments, while part three concludes with a review of computer-based technologies specific to apparel and apparel design, with themes ranging from 3D body scanning to the teaching of computer-aided design to fashion students.With its distinguished editor and international team of expert contributors, Computer technology for textiles and apparel is an invaluable tool for a wide range of people involved in the textile industry, from designers and manufacturers to fibre scientists and quality inspectors.

- Provides an overview of innovative developments in computer technology for a wide range of applications

- Covers structure and defect analysis, modelling and simulation and apparel design

- Themes range from 3D body scanning to the teaching of computer-aided design to fashion students

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Computer-based technology for textile materials

1

Digital technology for yarn structure and appearance analysis

B.G. Xu, The Hong Kong Polytechnic University, Hong Kong

Abstract:

Yarn structure and appearance are important characteristics in yarn quality assessment and assurance. This chapter presents the recent developments of digital technologies for yarn structure and appearance analysis. The chapter broadly reviews the latest advances that have been made in digital measurement and analysis of yarn evenness, yarn hairiness, yarn twist, yarn snarl, yarn blend and yarn surface appearance.

Key words

yarn structure

yarn appearance

yarn assessment

yarn image processing

digital signal processing

1.1 Introduction

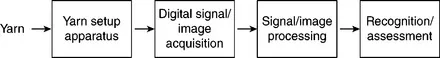

Yarn is used worldwide for making a wide range of textiles and apparel. Its structure and appearance have significant influence on the properties and performance of the yarn and its end-products. Therefore, the analysis of yarn structure and appearance is an important need and procedure in assessing yarn quality in the textile industry. Traditionally yarn structure and appearance are evaluated subjectively by manual methods, but some of the methods are subjective, less reliable and labour intensive. With the rapid development of computer technology, efficient and low-cost techniques have been established for the accurate image acquisition and massive image storage. At the same time, image processing, computer vision and pattern recognition have achieved their respective high levels of progress. Those developments in digital technology bring new data acquisition apparatus, new data analysis and recognition approaches, thus providing an alternative objective method for yarn feature analysis. A generic diagram of digitalized yarn feature analysis is shown in Fig. 1.1.

1.1 A generic diagram of digitalized yarn feature analysis.

In this chapter, we will present the state-of-the-art digital technologies for yarn structure and appearance analysis. More specifically, we look into the latest developments in yarn evenness measurement, yarn hairiness analysis, yarn twist and snarl measurements, yarn blend analysis and yarn surface appearance grading (Sections 1.2–1.7). Afterwards, we will discuss the future trend of this area in Section 1.8. Concluding remarks are drawn in Section 1.9.

1.2 Measurement of yarn evenness

Consistent yarn thickness is essential for the high quality of textile products. For many years, yarn irregularity has been measured by the capacitance evenness tester using two parallel capacitive sensors. The capacitance based method is accurate and stable in yarn mass measurement and has been well accepted in the textile industry for decades. Nevertheless this method can only give a rough description of yarn irregularity in diameter. Optical measurement alternatively provides a more accurate method in determining the yarn diameter and its variation by using optical sensors. As the diameter of a yarn is measured, the optical based method is not affected by moisture content or fibre blend variations in the yarn. The Uster evenness tester and the Zweigle G580 are two representative instruments commercially used in the textile industry for the capacitive and optical measurements of yarn evenness, respectively.

Recent developments in capacitive and optical measurements, along with the digital signal processing of analysis, make the yarn evenness results more practical and sensible. For instance, Rong and Slater (1995) developed a microcomputer system using digital signal processing for yarn unevenness analysis. In this system, the analogue signal of the diameters of a single yarn, measured by the Uster Tester, was converted into a digital form and then further analyzed by means of frequency spectrum analysis techniques. In addition to the traditional statistical parameters for characterizing irregularity, yarn unevenness could be assessed by using the probability density function, which was known to be closely correlated with fabric appearance quality. Based on the capacitive principle, Carvalho et al. (2006) also developed a new system for accurate yarn thickness and evenness measurement by using capacitive sensors and digital signal processing techniques. In comparison to commercial instruments, this system enabled direct measurement of yarn mass with a high resolution of 1 mm in yarn length. With the accurate measurements of yarn mass, some signal processing algorithms, such as FFT (Fast Fourier Transform) and FWHT (Fast Walsh–Hadamard Transform), were employed to detect a wide range of yarn faults in lengths of 1 mm and above.

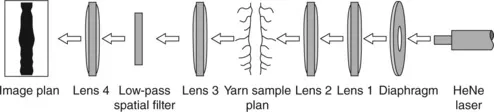

In optical measurement, an optical signal processing system has been developed (Carvalho et al., 2008) to measure yarn diameter. As shown in Fig. 1.2, a helium neon (HeNe) laser was used to emit a coherent light which was directed to pass through a diaphragm, a set of planoconvex lenses and a yarn sample and finally was received by a detector (photodiode). The novelty of this method is that a low-pass spatial filter was inserted in front of the optical sensor so as to eliminate the signal from yarn hairs and thus keep the entire core of the yarn remaining in the image for diameter evaluation. The working principle is based on the simple fact that the diameter of a spun yarn is usually one or more orders of magnitude larger than that of the small hairs (i.e. single fibres) protruding from its surface. Therefore, the low-pass spatial filter was able to eliminate all spatial frequencies above a predetermined value, covering the characteristic sizes of most textile fibres. As a result, the hairiness was almost completely removed in the yarn sample image before it was received by the optical detector. This system could also be easily adapted to measure the projection of the yarn diameter along a single direction and, consequently, to infer yarn irregularities.

1.2 Experimental setup of the optical system with a low-pass spatial filter for yarn diameter measurement (adapted from Carvalho et al., 2008).

1.3 Analysis of yarn hairiness

Yarn hairiness is defined as hairs protruding from the main body of a yarn. The amount of hairiness is important to both the textile operations and the appearance of fabrics and garments. Commercial instruments, such as the Uster Testers 3 and 4, the Shirley Hairiness Tester and the Zweigle G565 and G566, have been widely used in the textile industry for the assessment of yarn hairiness. So far, most commercial systems to quantify yarn hairiness have been based on the optical principle. Barella (1983) and Barella and Manich (2002) have systematically reviewed a wide range of measurement techniques and various commercial instruments designed for measuring yarn hairiness.

In addition to the traditional methods, digital analysis of high-quality images of a textile yarn can characterize hairiness. In this method, an image of high resolution or a microscope image with an appropriate magnification is usually adopted to ensure the clear presence of yarn hairs in the image. In the captured image, the yarn can be divided into two basic components: yarn core and hairiness. Yarn core refers to the main body of the yarn, which is composed of a compact agglomeration of fibres. As the yarn core and yarn hairs all consist of constituent fibres, they may present similar image features (e.g. colour, texture). Therefore, the main task (also a challenge) of this method is the segmentation or separation of yarn hairs or the core of the yarn from the background image. For this purpose, various image processing techniques such as the edge detection and thresholding algori...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Contributor contact details

- Woodhead Publishing Series in Textiles

- Introduction

- Part I: Computer-based technology for textile materials

- Part II: Modelling and simulation of textiles and garments

- Part III: Computer-based technology for apparel

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Computer Technology for Textiles and Apparel by Jinlian Hu in PDF and/or ePUB format, as well as other popular books in Computer Science & CAD-CAM. We have over one million books available in our catalogue for you to explore.