- 320 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Tribology for engineers discusses recent research and applications of principles of friction, wear and lubrication, and provides the fundamentals and advances in tribology for modern industry. The book examines tribology with special emphasis on surface topography, wear of materials and lubrication, and includes dedicated coverage on the fundamentals of micro and nanotribology. The book serves as a valuable reference for academics, tribology and materials researchers, mechanical, physics and materials engineers and professionals in related industries with tribology.

- Edited and written by highly knowledgeable and well-respected researchers in the field

- Examines recent research and applications of friction, wear and lubrication

- Highlights advances and future trends in the industry

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1

Surface topography

P. Sahoo, Jadavpur University, India

Abstract:

This chapter discusses the approaches to solid surface topography characterization including the surface layers, roughness parameters and statistical aspects. The multiscale characterization of surface topography in terms of fractal analysis, Fourier transform and wavelet transformation is also considered. The measurement techniques for surface roughness evaluation are discussed in terms of surface profilometry, optical methods and electron microscopy including the advanced techniques like scanning tunnelling microscopy and atomic force microscopy.

Keywords

surface layers

roughness parameters

multiscale characterization

measurement techniques

1.1 Introduction

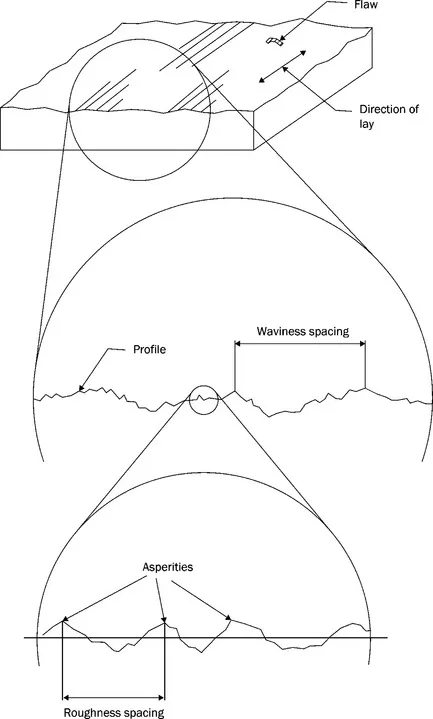

Surface interactions are dependent both on the contacting materials and the shape of the surface. The shape of the surface of an engineering material is a function of both its production process and the nature of the parent material (Bhushan, 1996; Thomas, 1982; Whitehouse, 1994). When studied carefully on a very fine scale, all solid surfaces are found to be rough, the roughness being characterized by asperities of varying amplitudes and spacing. The distribution of the asperities are found to be directional when the finishing process is direction dependent, such as turning, milling, etc., and homogeneous for a non-directional finishing process like lapping, electro-polishing, etc. For the study of tribological behaviour it is essential to know the methods of measuring and describing the surface shape in general and the surface roughness in particular. The surface texture may include (a) roughness (nano- and micro-roughness), (b) waviness (macro-roughness), (c) lay and (d) flaw. Figure 1.1 shows a display of surface texture with uni-directional lay. Roughness is produced by fluctuations of short wavelengths characterized by asperities (local maxima) and valleys (local minima) of varying amplitudes and spacing. This includes the features intrinsic to the production process. Waviness is the surface irregularities of longer wavelengths and may result from such factors as machine or work piece deflections, vibration, chatter, heat treatment or warping strains. Lay is the principal direction of the predominant surface pattern, usually determined by the production process. Flaws are unexpected and unintentional interruptions in the texture. Apart from these, the surface may contain large deviations from nominal shape of very large wavelength, which is known as error of form. These are not considered as part of surface texture.

Figure 1.1 Display of surface texture

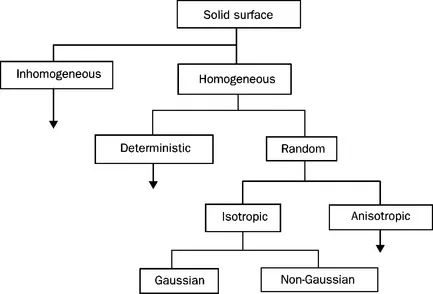

A very general typology of a solid surface is shown in Fig. 1.2. Deterministic surface textures may be studied by simple analytical methods. However, for most engineering surfaces, the textures are random, either isotropic or anisotropic, and either Gaussian or non-Gaussian; the exact type depends on the nature of the processing technique. So called cumulative processes such as peening, lapping and electro polishing where the final shape of each region is the cumulative outcome of a large number of random discrete local events and independent of the distribution governing each individual event, produce surfaces that are governed by the Gaussian form. It is a direct result of the central limit theorem of statistical theory. Extreme-value processes such as grinding and milling and single-point processes such as turning and shaping usually produce anisotropic and non-Gaussian surfaces.

Figure 1.2 General typology of surfaces

1.2 Characteristics of surface layers

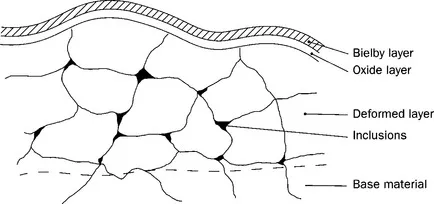

The surface of a solid body is the geometrical boundary between the solid and the environment. But in tribological terms, surface includes the near-surface material to a significant depth. The surface of a typical metal consists of several layers whose physio-chemical properties are significantly different from that of the bulk material (Buckley, 1981). Such a typical metal surface with different layers is shown in Fig. 1.3. The top layer known as the Bielby layer, results from the melting and surface flow during the machining of molecular layers that are subsequently hardened by quenching as they are deposited on the cool underlying material. The layer is of amorphous or microcrystalline structure and thickness typically ranges from 1 to 100 nm. This is followed by a compound oxide layer, which is produced from the chemical reaction of the metal with the environment. Besides this, there may be absorbed films that are produced either by physisorption or chemisorption of oxygen, water vapour and hydrocarbons. In physisorption, no exchange of electrons takes place between the molecules of the absorbent and the absorbate. This involves van der Waals forces. In chemisorption, an actual sharing of electrons or electron interchange occurs between the chemisorbed species and the solid surfaces, and the solid surface bonds very strongly to the adsorption species through covalent bonds. The chemisorption layer is always monomolecular while physisorbed layers may be monomolecular or polymolecular. Heat of absorption for chemisorption (10 to 100 kcal/mol) is more than that for physisorption (1 to 2 kcal/mol) and chemisorption requires certain activation energy while physisorption needs no such energy. The thickness of oxide and chemically reacted layer ranges from 10 to 100 nm. Below this lies the deformed layer of the material containing some entrapped lubricants and contaminants followed by the bulk material. The thickness of the deformed layer ranges from 1 to 100 microns.

Figure 1.3 Typical surface layers

The tendency of molecules to absorb on the surface and the chemical reactivity may be regarded as extrinsic properties of the surface. The important intrinsic property of the surface is the surface tension or free surface energy, which is basically the reversible work required to create a unit area of the surface at constant volume, temperature and chemical potential. The creation of a new surface implies not only mechanical work but also heat consumption if the process occurs isothermally. The value of the surface energy of a material depends on the nature of the medium on the other side of the material boundary. Numerous surface analytical techniques are commercially available for the characterization of surface layers. The metallurgical properties like grain structure of the deformed layer can be obtained by sectioning the surface and examining the cross-section with the help of a high-resolution optical microscope or a scanning electron microscope (SEM). A transmission electron microsco...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface

- List of figures

- List of tables

- About the contributors

- Chapter 1: Surface topography

- Chapter 2: Friction and wear

- Chapter 3: Lubrication and roughness

- Chapter 4: Micro/nano tribology

- Chapter 5: Tribology in manufacturing

- Chapter 6: Bio and medical tribology

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Tribology for Engineers by J. Paulo Davim,J Paulo Davim in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mechanical Engineering. We have over one million books available in our catalogue for you to explore.