- 320 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Corrosion Control in the Aerospace Industry

About This Book

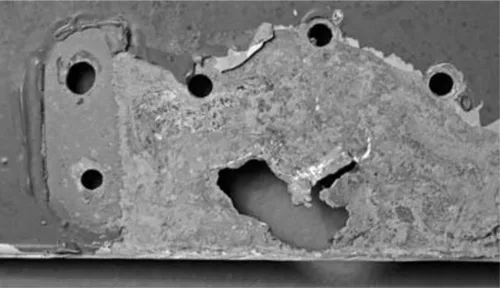

Corrosion control in the aerospace industry has always been important, but is becoming more so with the ageing of the aircraft fleet. Corrosion control in the aerospace industry provides a comprehensive review of the subject with real-world perspectives and approaches to corrosion control and prevention.Part one discusses the fundamentals of corrosion and the cost of corrosion with chapters on such topics as corrosion and the threat to aircraft structural integrity and the effect of corrosion on aluminium alloys. Part two then reviews corrosion monitoring, evaluation and prediction including non-destructive evaluation of corrosion, integrated health and corrosion monitoring systems, modelling of corrosion and fatigue on aircraft structures and corrosion control in space launch vehicles. Finally, Part three covers corrosion protection and prevention, including chapters which discuss coating removal techniques, novel corrosion schemes, greases and their role in corrosion control and business strategies in fleet maintenance.With its distinguished editor and team of expert contributors, Corrosion control in the aerospace industry is a standard reference for everyone involved in the maintenance and daily operation of aircraft, as well as those concerned with aircraft safety, designers of aircraft, materials scientists and corrosion experts.

- Discusses the fundamentals of corrosion and the cost of corrosion to the aerospace industry

- Examines the threat corrosion poses to aircraft structural integrity and the effect of corrosion on the mechanical behaviour of aircraft

- Reviews methods for corrosion monitoring, evaluation and prediction examining both current practices and future trends

Frequently asked questions

Information

Corrosion in the aerospace industry

Abstract

1.1 Introduction

1.2 Aerospace corrosion

1.2.1 Corrosion and structural integrity

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright page

- Contributor contact details

- 1: Corrosion in the aerospace industry

- Part I: Corrosion fundamentals and cost of corrosion

- Part II: Corrosion monitoring, evaluation and prediction

- Part III: Corrosion protection and prevention

- Index