- 870 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Handbook of Conveying and Handling of Particulate Solids

About This Book

This handbook presents comprehensive coverage of the technology for conveying and handling particulate solids. Each chapter covers a different topic and contains both fundamentals and applications. Usually, each chapter, or a topic within a chapter, starts with one of the review papers. Chapter 1 covers the characterization of the particulate materials. Chapter 2 covers the behaviour of particulate materials during storage, and presents recent developments in storage and feeders design and performance. Chapter 3 presents fundamental studies of particulate flow, while Chapters 4 and 5 present transport solutions, and the pitfalls of pneumatic, slurry, and capsule conveying. Chapters 6, 7 and 8 cover both the fundamentals and development of processes for particulate solids, starting from fluidisation and drying, segregation and mixing, and size-reduction and enlargement. Chapter 9 presents environmental aspects and the classification of the particulate materials after they have been handled by one of the above-mentioned processes. Finally, Chapter 10 covers applications and developments of measurement techniques that are the heart of the analysis of any conveying or handling system.

Frequently asked questions

Information

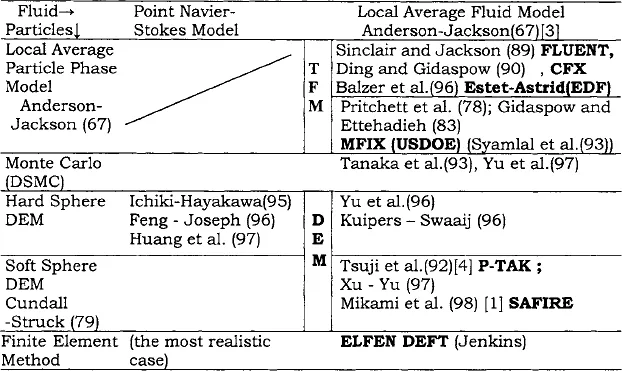

DEM simulation of industrial issues in fluidized bed reactors

1 INTRODUCTION

Table of contents

- Cover image

- Title page

- Table of Contents

- Handbook of Powder Technology

- Front Matter

- Copyright page

- Preface

- Solids flowability measurement and interpretation in industry

- Flow properties of bulk solids -which properties for which application

- Investigation on the effect of filling procedures on testing of flow properties by means of a uniaxial tester

- Characterization of powder flow behavior with the Flexible Wall Biaxial Tester

- From discrete element simulations towards a continuum description of particulate solids

- Vibrational flow of cohesive powders

- Influence of the stress history on the time dependent behaviour of bulk solids

- Evaluation of the mechanical properties of powder for storage

- Particle adhesion and powder flow behaviour

- Determination of the influence of surface coating and particle size on flow properties of organic pigment powders

- The conversion of the analytical simple shear model for the Jenike failure locus into principal stress space and implication of the model for hopper design

- Modelling flooding in a small vessel compared with experiments and numerical calculation

- Analysis and application of powder compaction diagrams

- Axial porosity distribution in a packed bed of deformable particles: A numerical study based on DEM

- Flow properties of bulk solids and their use in solving industrial problems

- Silo failures: case histories and lessons learned

- The relationship between flow behaviour in a plane flow hopper and the jenike design method

- Full scale silo tests and numerical simulations of the „cone in cone” concept for mass flow

- Stress condition of sliding bulk solids on silo walls

- Studies on thermal actions and forces in cylindrical storage silo bins

- Silo discharge: Dynamic effects of granular flow

- Recent developments in feeder design and performance

- Recent developments in belt conveying - bulk solid and conveyor belt interactions

- Putting the pedal to the metal

- Mesoscopic nature of granular flows

- Using a kinetic theory approach incorporating interaction with the air to model granular flow down a chute

- Numerical and experimental studies for the impact of projectiles on granular materials

- Implementation of 3D frictional contact condition

- Numerical simulation of 3D iron ore flow

- Pneumatic conveying: transport solutions, pitfalls, and measurements

- Dilute-phase pneumatic conveying problems and solutions

- Latest development of the direct technique for measurement of the pneumatic conveying characteristics of bulk materials

- Dense phase (plug) conveying – observations and projections

- Operating limits of low-velocity pneumatic conveying

- Granular jump in low velocity pneumatic conveying of solid particles in a horizontal pipeline

- Two-layer model for non-suspension gas-solids flow of fine powders in pipes

- Pressure drop prediction of low-velocity slug-flow materials in the unstable zone

- Transportation boundaries for horizontal slug-flow pneumatic conveying

- The use of high pressure blow tanks for the pneumatic conveying of pelletised materials

- Pneumatic conveying with Turbuflow®-advantages against conventional dense phase conveying

- The influence of a bend on the flow characteristics in pneumatic conveying systems

- A novel analytical model for the acceleration of particles following bends in pneumatic conveying systems

- The design of pipeline systems for transporting ice into deep mines

- Experimental studies on pneumatic conveying of wet snow

- Deposition velocities for slurry flows

- Particle motion in sheared non-Newtonian media

- Distribution and friction of particles in pipeline flow of sand-water mixtures

- Laminar and turbulent flow of dense kaolin and ash hydromixtures

- Rheological characterization of industrial kaolin slurries

- Net positive suction head requirement for centrifugal slurry pumps

- Slurry and tip clearance effects on the performance of an open impeller centrifugal pump

- Pneumatic capsule pipelines in Japan and future developments

- Drag reduction in hydraulic capsule pipeline

- A contribution to hydrotransport of capsules in bend and inclined pipeline sections

- Recent developments in the drying technologies for the production of particulate materials

- DEM simulation of industrial issues in fluidized bed reactors

- Rheologic and flow properties of fluidised bulk solids

- Drying kinetics simulation by means of artificial neural networks

- Production of powder-like material from suspension by drying on inert particles

- Segregation of powders - mechanisms, processes and counteraction

- Countering segregation

- An investigation of degradation and segregation in typical coal handling processes

- A system for the reduction of air current segregation in silos

- Segregation-free particle mixing

- Bulk-solids mixing: overview

- A double stochastic model of the mixing of solid particles

- Investigation of flow regimes in continuous mixer tubes

- Description of grinding in a ball mill using statistical moments

- A Markov chain model to describe the Residence Time Distribution in a stirred bead mill

- Simulation of interaction of opposed gas-particle jets

- Simulation of gas-particle flows in jet-vortex mills

- Contribution to the theory of roll press design

- Drum granulation conditions for raw material with different particle size distributions

- Fugitive and non-fugitive dust generation and control in eonveying of powders: reality, technology and human attitude

- Evaluation of air pollution level by means of artificial neural network - multilayer perceptron

- Dust explosion hazard considerations for materials handling plants

- A de-dusting device for removing fines from pellets and granules

- Assessment of a multistage gravity separation in turbulent air flow

- TriboMechanical classification: A new technology for size classification of bulk powders

- Particle surface inspection with Fourier-wavelets transform

- The crucial role of on-line measurement in bulk solids handling

- Application of non-invasive techniques for imaging fluidized beds – A review

- Electrical tomography techniques for multiphase flow applications

- Sedimentation kinetics monitor

- Effect of mass loading on gas-solids motion and particle segregation patterns

- Measurement of the dynamic behavior of bulk solids using optical flow analysis