![]()

Part I

The basics of maintenance and reliability

![]()

CHAPTER

1 Understanding Maintenance and Reliability

1.1. THE MAINTENANCE FUNCTION

The ultimate goal of maintenance is to provide optimal reliability that meets the business needs of the company, where reliability is defined as "the probability or duration of failure-free performance under stated conditions." Although many organizations view maintenance as adding little value to the firm, when properly developed and managed, it preserves the company’s assets to meet the need for reliability at an optimal cost.

John Day, formerly the maintenance and engineering manager for Alumax Mt. Holly, was one of the best-known proactive maintenance management advocates and my mentor and manager for a number of years. John spoke all over the world about his model of proactive maintenance. His insight into what a successful plant considers "maintenance" provides us the section that follows.

1.2. STRATEGY TO ACHIEVE WORLD-CLASS PRODUCTION THROUGH RELIABILITY*

Alumax of South Carolina is an aluminum smelter that produces in excess of 180,000 MT of primary aluminum each year. It began operation in 1980 after a two-year construction phase. The plant is the last greenfield aluminum smelter constructed in the U.S. Alumax of SC is a part of Alumax, Inc., which has headquarters in Norcross, Georgia; a suburb of Atlanta, Georgia. Alumax, Inc. is the third largest producer of primary aluminum in the U.S. and the fourth largest in North America.

The vision of general management was that the new smelter located on the Mt. Holly Plantation near Charleston, SC, would begin operations with a planned maintenance system that could be developed into a total proactive system. At the time in 1978–79, there were no maintenance computer systems available on the market with the capability to support and accomplish the desired objectives. Thus TSW of Atlanta, Georgia was brought on site to take not only the Alumax of SC maintenance concepts and develop a computer system, but they were to integrate all the plant business functions into one on-line common data base system available to all employees in their normal performance of duties.

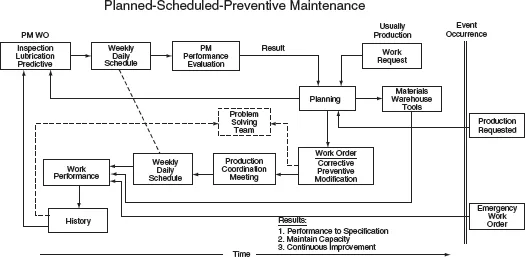

Since the development and initial operation of the Alumax of SC maintenance management system, it has matured and rendered impressive results. These results have received extensive recognition on a national and international level. The first major recognition came in 1984 when Plant Engineering magazine published a feature article about the system. Then in 1987 A. T. Kearney, an international management consultant headquartered in Chicago, performed a study to find the best maintenance operations in North America. Alumax of SC was selected as one of the seven "Best of the Best." And in 1989, Maintenance Technology magazine recognized Alumax of SC as the best maintenance operation in the U.S. within its category and also as the best overall maintenance operation in any category. Mt. Holly’s proactive model is shown in Figure 1.1.

1.2.1. Maintenance Approaches

From a basic point of view there are two maintenance approaches. One approach is reactive and the other is proactive. In practice there are many combinations of the basic approaches. The reactive system (see Figure 1.1) responds to a work request or identified need, usually production identified, and depends on rapid response measures if effective. The goals of this approach are to reduce response time to a minimum (the computer helps) and to reduce equipment down time to an acceptable level. This is the approach used by most operations today. It may well incorporate what is termed as a preventative maintenance program and may use proactive technologies.

The proactive approach (see Figure 1.2) responds primarily to equipment assessment and predictive procedures. The overwhelming majority of corrective, preventative, and modification work is generated internally in the maintenance function as a result of inspections and predictive procedures. The goals of this method are continuous equipment performance to established specifications, maintenance of productive capacity, and continuous improvement. Alumax of SC practices the proactive method. The comments which follow are based upon the experience and results of pursuing this vision of maintenance.

1.2.2. Maintenance Management Philosophy

Alumax of SC began development of the maintenance management concept with the idea that maintenance would be planned and managed in a way that provides an efficient continuous operating facility at all times. Add to this that maintenance would also be treated as an investment rather than a cost, and you have the comprehensive philosophy on which the maintenance management system was built. An investment is expected to show a positive return, and so should maintenance be expected to improve the profitability of an operation. The management philosophy for maintenance is just as important as the philosophy established for any business operation. For most industry, maintenance is a supervised function at best, with little real cost control. But it must be a managed function employing the best methods and systems available to produce profitable results that have a positive effect on profitability.

The development of a philosophy to support the concept of proactive planned maintenance is important. It is believed that many maintenance management deficiencies or failures have resulted from having poorly constructed philosophies or the reliance upon procedures, systems, or popular programs that have no real philosophical basis.

1.2.3. The Function and Control System

Today there is little disagreement that the function and control system of a good maintenance management program must be computer based.

Using the philosophy that maintenance management is to be considered in the same way that all other business functions are considered, it is difficult to justify any other approach other than complete integration of maintenance management functions with total organizational management functions. The computer is the tool to use to accomplish this difficult and complex task.

The computer, in an integrated operation, must be available for use by every member of the maintenance organization as well as all other plant employees who have a need. It is an essential part of the maintenance employee’s resources for accomplishing his work. It is just as important to a mechanic or electrician as the tools in his toolbox or the analysis and measurement instruments that he uses daily.

The computer must supply meaningful and useful information to the user as opposed to normal computer data.

A successful integration of data systems will tie together maintenance, warehouse, purchasing, accounting, engineering, and production in such a way that all parties must work together and have the use of each other’s information. This is part of the answer to the question being asked almost universally, how do you break down the barriers between departments and get them to work as part of the whole or as a team? The computer system must be on line, available, and time responsive. A batch system or semi-batch system will not provide the support needed for a dynamic, integrated, maintenance management system.

In the integrated system with a common data base, data is entered only once and immediately updates all other files so that its use is immediately available to all functional areas. This means that anyone in any functional area can use or look at data in any other area, unless it is restricted. Some have referred to this effect as the "fish bowl effect" since everything is visible to all. This stimulates cooperation, in fact, it dictates cooperation.

1.2.4. What Is Maintenance?

Everyone knows what maintenance is; or at least they have their own customized definition of maintenance. If the question is asked, words like fix, restore, replace, recondition, patch, rebuild, and rejuvenate will be repeated. And to some extent there is a place for these words or functions in defining maintenance. However, to key the definition of maintenance to these words or functions is to miss the mark in understanding maintenance, especially if you wish to explore the philosophical nature of the subject. Maintenance is the act of maintaining. The basis for maintaining is to keep, preserve, and protect. That is to keep in an existing state or preserve from failure or decline. There is a lot of difference between the thoughts contained in this definition and the words and functions normally recalled by most people who are "knowledgeable" of the maintenance function; i.e., fix restore, replace, recondition, etc.

1.2.5. Specification

If we shift our defining thoughts to maintenance in the pure sense, we force ourselves to deal with keeping, preserving, and protecting. But what are we to keep, protect, or preserve? You may think that it is the machine, equipment, or plant, and that is true. But how are you to define the level to which the machine, equipment, or plant is to be kept. One way would be to say—"keep it like new." At face value the concept sounds good, but it is more subjective than objective. The answer to maintenance levels must be defined by a specification.

A specification is a detailed precise presentation of that which is required. We must have a specification for the maintenance of equipment and plant. In actual usage today the specification, if it exists, is not detailed or precise. A specification usually does exist informally in the mind of the mechanic or management member even though they may be unable to recite it. This means that at best, it is a variable, general-type specification. This kind of specification is defined in terms of and is dependent upon time available, personnel training level, pressure to produce a current order now, money allocated or available, or management opinion. Obviously, a specification like this will not qualify as a true specification, nor will it qualify as a supporting component of the act of maintaining. The true maintenance specification may be a vendor specification, a design specification, or an internally developed specification. The specification must be precise and objective in its requirements. The maintenance system and organization must be designed to support a concept based on rational specifications. Detailed work plans and schedules may be constructed to provide the specification requirement at the maintenance level. In the maintaining context, the specification is not a goal. It is a requirement that must be met. The maintenance system must be designed to meet this requirement. The specification must be accepted as the "floor" or minimum acceptable maintenance level. Variation that does occur should be above the specification level or floor. The specifications will probably be stated in terms of attributes and capacity.

In reference to maintenance specifications, included are individual equipment specifications, process specifications, and plant performance specifications.

1.2.6. The Maintenance Function

The maintenance department is responsible and accountable for maintenance. It is responsible fo...