Safety Critical Systems Handbook

A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849

- 288 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Safety Critical Systems Handbook

A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849

About This Book

Safety Critical Systems Handbook: A Straightfoward Guide to Functional Safety, IEC 61508 (2010 Edition) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 AND ISO 13849, Third Edition, offers a practical guide to the functional safety standard IEC 61508. The book is organized into three parts. Part A discusses the concept of functional safety and the need to express targets by means of safety integrity levels. It places functional safety in context, along with risk assessment, likelihood of fatality, and the cost of conformance. It also explains the life-cycle approach, together with the basic outline of IEC 61508 (known as BS EN 61508 in the UK). Part B discusses functional safety standards for the process, oil, and gas industries; the machinery sector; and other industries such as rail, automotive, avionics, and medical electrical equipment. Part C presents case studies in the form of exercises and examples. These studies cover SIL targeting for a pressure let-down system, burner control system assessment, SIL targeting, a hypothetical proposal for a rail-train braking system, and hydroelectric dam and tidal gates.

- The only comprehensive guide to IEC 61508, updated to cover the 2010 amendments, that will ensure engineers are compliant with the latest process safety systems design and operation standards

- Helps readers understand the process required to apply safety critical systems standards

- Real-world approach helps users to interpret the standard, with case studies and best practice design examples throughout

Frequently asked questions

Information

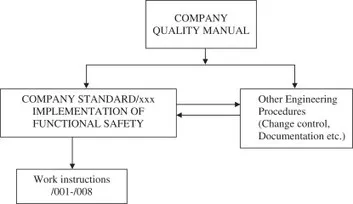

Appendix 1 Functional Safety Management

- Purpose of Document

- Scope

- Functional Safety Policy

- Quality & Safety Plan

- Competencies

- Review of Requirement and Responsibilities

- Source of the requirement

- Contract or project review

- Assigning responsibilities

-

- Functional Safety Specification

- Life Cycle Activities

- Integrity Targeting

- Random Hardware Failures

- ALARP

- Architectures

- Life-cycle activities

- Functional Safety Capability

-

- Implementation

- Validation

- Work Instruction xxx/001 – Random Hardware Failures & ALARP

- Work Instruction xxx/002 – Integrity Targeting

- Work Instruction xxx/003 – Life Cycle Activities

- Work Instruction xxx/004 – Architectures (SFF)

- Work Instruction xxx/005 – Rigour of Life Cycle Activities

- Work Instruction xxx/006 – Functional Safety Competence

- Work Instruction xxx/007 – Functional Safety Plan

- Work Instruction xxx/008 – Functional Safety Specification

- Individuals’ attendance at relevant off-the-job courses

- Records of SR experience from each project (on-the-job training) (Project Managers will provide this information to the Personnel Manager)

- Details of new employees or contractors.

Table of contents

- Cover

- Title Page

- Copyright

- Table of Contents

- IEC 61508

- A Quick Overview

- The 2010 Version of IEC 61508

- Acknowledgements

- Part A: The Concept of Safety Integrity

- Part B: Specific Industry Sectors

- Part C: Case Studies in the Form of Exercises and Examples

- Appendix 1: Functional Safety Management

- Appendix 2: Assessment Schedule

- Appendix 3: Betaplus CCF Model, Scoring Criteria

- Appendix 4: Assessing Safe Failure Fraction and Diagnostic Coverage

- Appendix 5: Answers to Examples

- Appendix 6: References

- Appendix 7: Quality and Safety Plan

- Appendix 8: Some Terms and Jargon of IEC 61508

- Index