- 484 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Additives for Plastics Handbook

About this book

Both technically and economically, additives form a large and increasingly significant part of the polymer industry, both plastics and elastomers. Since the first edition of this book was published, there have been wide-ranging developments, covering chemistry and formulation of new and more efficient additive systems and the safer use of additives, both by processors in the factory and, in the wider field, as they affect the general public.This new edition follows the successful formula of its predecessor, it provides a comprehensive view of all types of additives, concentrating mainly on their technical aspects (chemistry/formulation, structure, function, main applications) with notes on the commercial background of each. The field has been expanded to include any substance that is added to a polymer to improve its use, so including reinforcing materials (such as glass fibre), carbon black and titanium dioxide. This is a book which has been planned for ease of use and the information is presented in a way which is appropriate to the users' needs.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

An Overview of Additives

| Type | Main applications |

| Additives | Products, normally used in small quantities, which enhance the value of materials such as plastics, paints, colour prints, and lubricants, by improving their processability, performance, and appearance during manufacture and in use. |

| Antimicrobials | Substances that prevent the growth of microbes and give consumer products such as soaps and toothpastes a medicated property. |

| Coatings | The broad term for paints, inks, and lacquers. While often associated with decoration, coatings also protect surfaces from corrosion and damage. |

| Colours | Can be soluble dyes for textiles, leather, paper, or insoluble pigments for plastics, coatings, and printing inks. |

| Fine chemicals | Highly complex functional intermediates or ingredients for ‘high-tech’ applications: for example, in the pharmaceutical, agrochemical, and electronic industries. |

| Heat and light stabilizers | Additives that prevent the degradation of plastics and coatings under the effects of heat, oxygen, and light. |

| Optical brighteners | Chemicals which impart whiteness to textiles, detergents, paper, fibres, and plastics. |

| Photo/repro additives | Additives that, when irradiated with light, promote the hardening of printing inks, coatings, and adhesives, and chemically fix images used in electronic or graphic materials. |

| Pigments | Colorants that remain undissolved before, during, and after application: they are used to colour plastics, inks, paints, and synthetic fibres. |

| UV curing | Hardening of coatings and adhesives by means of ultraviolet light. |

| Water treatments | Help purify water for industrial and domestic applications. They also modify water as an agent for the processing of minerals and oils, and have a variety of properties to process water (for example, flocculants separate water from solid particles). |

| Type | Examples | Functions |

| Fillers and mineral reinforcements | Calcium carbonate, talc, mica | Adding bulk to a compound: increasingly used to improve stiffness, surface hardness |

| Fibre reinforcements | Aramid, carbon, glass, natural fibres | Mechanical strength: used as short fibre, long fibre, spheres |

| Colorants | Pigments, liquid colours, colour pastes, dyestuffs, special effects | Virtually unlimited, added as powders or liquids: easier mixing, replacement of heavy metals |

| Black and white pigments | Carbon black, titanium dioxide | Also for improved UV resistance and (carbon black) electrical conductivity |

| Heat resistance | Antioxidants and stabilizers | Act to delay/prevent oxidation of polymer under heat, during processing or application |

| UV resistance | UV stabilizers | Delay/prevent oxidation of end-product under prolonged exposure to ... |

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- LIST OF TABLES

- LIST OF FIGURES

- Preface

- Chapter 1: An Overview of Additives

- Chapter 2: Types of Additive and the Main Technical Trends

- Chapter 3: The World Market

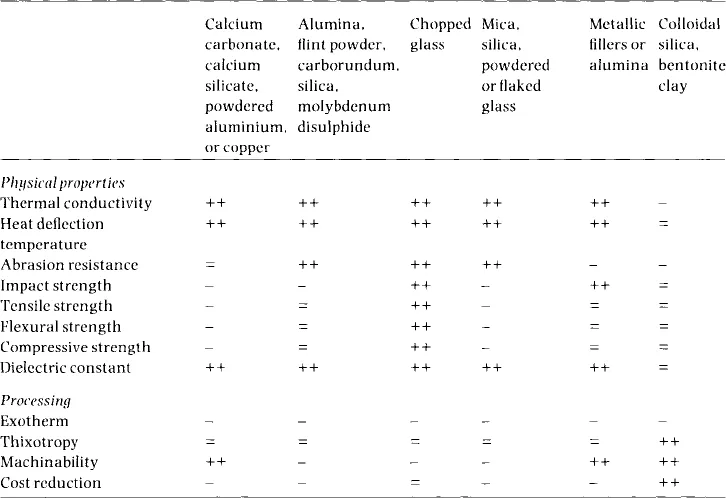

- Chapter 4: Modifying Specific Properties: Mechanical Properties – Fillers

- Chapter 5: Modifying Specific Properties: Mechanical Properties – Reinforcements

- Chapter 6: Modifying Specific Properties: Appearance – Colorants, Pigments, Dyes, Special Effects

- Chapter 7: Modifying Specific Properties: Appearance – Black and White Pigmentation

- Chapter 8: Modifying Specific Properties: Resistance to Heat – Heat Stabilizers

- Chapter 9: Modifying Specific Properties: Resistance to Light – UV Stabilizers

- Chapter 10: Modifying Specific Properties: Flammability – Flame Retardants

- Chapter 11: Modifying Specific Properties: Conductivity – Antistatic/Conductive Additives

- Chapter 12: Modifying Processing Characteristics: Curing and Cross-linking

- Chapter 13: Modifying Processing Characteristics: Coupling, Compatibilizing Agents

- Chapter 14: Modifying Processing Characteristics: Plasticizers

- Chapter 15: Modifying Processing Characteristics: Blowing Agents

- Chapter 16: Modifying Processing Characteristics: Modifiers and Processing Aids

- Chapter 17: Modifying Processing Characteristics: Lubricants, Mould Release Agents, Anti-slip and Anti-blocking

- Chapter 18: Other Types of Additive: Miscellaneous Additives

- Chapter 19: Other Types of Additive: Additives for Rubber

- Chapter 20: Other Types of Additive: Additives for Recycling

- Chapter 21: Background Information: Equipment – Mixing, Compounding, and Dosing

- Chapter 22: Background Information: Health and Safety

- Chapter 23: Background Information: Legislation and Testing

- APPENDIX A: Conversion Tables

- APPENDIX B: Technical Terms

- APPENDIX C: Standard Abbreviations for Plastics and Elastomers

- APPENDIX D: Trade Names

- APPENDIX E: Directories

- DATA SHEETS

- EDITORIAL INDEX

- INDEX OF ADVERTISERS

Frequently asked questions

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app