eBook - ePub

Micromechanism of Cleavage Fracture of Metals

A Comprehensive Microphysical Model for Cleavage Cracking in Metals

This is a test

- 486 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Micromechanism of Cleavage Fracture of Metals

A Comprehensive Microphysical Model for Cleavage Cracking in Metals

Book details

Book preview

Table of contents

Citations

About This Book

In this book the authors focus on the description of the physical nature of cleavage fracture to offer scientists, engineers and students a comprehensive physical model which vividly describes the cleavage microcracking processes operating on the local (microscopic) scale ahead of a defect. The descriptions of the critical event and the criteria for cleavage fracture will instruct readers in how to control the cleavage processes and optimize microstructure to improve fracture toughness of metallic materials.

- Physical (mechanical) processes of cleavage fracture operating on the local (microscopic) scale, with the focus on the crack nucleation and crack propagation across the particle/grain and grain/grain boundaries

- Critical event, i.e., the stage of greatest difficulty in forming the microcrack, which controls the cleavage fracture

- Criteria triggering the cleavage microcracking with incorporation of the actions of macroscopic loading environment into the physical model

- Effects of microstructure on the cleavage fracture, including the effects of grain size, second phase particles and boundary

- Comprehensive description of the brittle fracture emerging in TiAl alloys and TiNi memory alloys

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Micromechanism of Cleavage Fracture of Metals by Jianhong Chen,Rui Cao in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mining Engineering. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Introduction

Abstract

In this chapter basic concepts of fracture, including different fracture modes under various stress states, concepts of cleavage fracture, and essentials of the micromechanism (microphysical model) of cleavage fracture are introduced. A brief explanation of basic theories used for establishing the micromechanism of cleavage fracture is set forth. Special attention is focused on the concepts of stress and strain concentration, stress triaxiality, and stress intensification. Distributions of stress and strain ahead of a notch or a precrack are depicted. Finally, the recent results of research work on the micromechanism of cleavage fracture of steels are briefly reviewed.

Keywords

Fracture mode

Micromechanism

Microphysical model

Cleavage fracture

Stress concentration

Stress triaxiality

Stress intensification

Stress and strain distribution

1.1 Basic Concepts of Fracture

Before providing a comprehensive elaboration of the micromechanism of cleavage fracture, in this section we give a brief description of fracture modes occurring under various stress states, the concepts of cleavage fracture, and the essentials of the micromechanism of cleavage fracture. (Nomenclatures of stress and strain are defined in Section 1.2.)

1.1.1 Fracture Modes Under Various Stress States

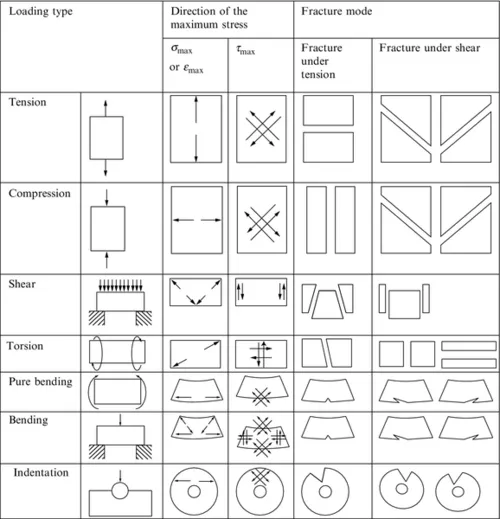

Figure 1.1, which is adapted from the book, Science of Strength for Materials, edited by Professor Chen (1987), demonstrates the driving stresses or strain and the corresponding macroscopic fracture modes under various loading types.

Figure 1.1 Illustration of various stress states and corresponding macroscopic fracture modes under various loading types. Note: σmax, maximum normal stress; εmax, maximum normal strain; τmax, maximum shear stress (Chen, 1987).

On the macroscopic scale, according to the global plastic deformation before the fracture, fracture is classified into two macroscopic categories: brittle fracture, without or with little global plastic deformation before fracture; and ductile rupture, with appreciable global plastic deformation before fracture. A third category, quasi-brittle fracture, is sometimes specified as characterized by less brittleness compared to brittle fracture.

As shown in Figure 1.1, under various applied loading types, the stresses are resolved to normal tensile stress σ and shear stress τ. Fracture modes produced by the tension stresses are of normally opening fracture, which are different from that produced by the shear stresses, which are of slip-induced rupture. The former modes show characteristics more brittle than the latter modes.

Fracture modes are also distinguished as those that occur in plane strain state and those that occur in plane stress state. Plane strain state is produced in very thick specimens where the strain in the thickness direction can be ignored, i.e., εzz = 0. Then σzz = ν(σxx + σyy) ≠ 0, and it establishes a triaxial stress state with a triaxiality defined by σm/σe in Section 1.2. Plane stress state is produced in thin specimens, where the stress in the thickness direction can be ignored, i.e., σzz = 0. Then, the stress state presents a biaxial stress state rather than a triaxial one. The plane strain state is much more strict than the plane stress state, and the fracture occurring in the former state is more brittle than that in the latter state. The criteria for cleavage fracture sp...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Dedication

- Acknowledgments

- Preface

- Chapter 1: Introduction

- Chapter 2: Methodology

- Chapter 3: Microphysical Processes of Cleavage Fracture of Steels

- Chapter 4: Critical Event for Cleavage Fracture

- Chapter 5: Criteria for Cleavage Fracture

- Chapter 6: Effects of Material Microstructure on Cleavage Fracture

- Chapter 7: Global Fracture Toughness Related to the Micromechanism of Cleavage Fracture

- Chapter 8: Special Case Studies

- Chapter 9: Brittle Fracture of TiAl Alloys and NiTi Memory Alloys

- Nomenclature

- Index