Mechanics of Materials Volume 1

An Introduction to the Mechanics of Elastic and Plastic Deformation of Solids and Structural Materials

- 450 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Mechanics of Materials Volume 1

An Introduction to the Mechanics of Elastic and Plastic Deformation of Solids and Structural Materials

About This Book

One of the most important subjects for any student of engineering to master is the behaviour of materials and structures under load. The way in which they react to applied forces, the deflections resulting and the stresses and strains set up in the bodies concerned are all vital considerations when designing a mechanical component such that it will not fail under predicted load during its service lifetime.All the essential elements of a treatment of these topics are contained within this course of study, starting with an introduction to the concepts of stress and strain, shear force and bending moments and moving on to the examination of bending, shear and torsion in elements such as beams, cylinders, shells and springs. A simple treatment of complex stress and complex strain leads to a study of the theories of elastic failure and an introduction to the experimental methods of stress and strain analysis.More advanced topics are dealt with in a companion volume - Mechanics of Materials 2. Each chapter contains a summary of the essential formulae which are developed in the chapter, and a large number of worked examples which progress in level of difficulty as the principles are enlarged upon. In addition, each chapter concludes with an extensive selection of problems for solution by the student, mostly examination questions from professional and academic bodies, which are graded according to difficulty and furnished with answers at the end.* Emphasis on practical learning and applications, rather than theory* Provides the essential formulae for each individual chapter* Contains numerous worked examples and problems

Frequently asked questions

Information

SIMPLE STRESS AND STRAIN

1.1 Load

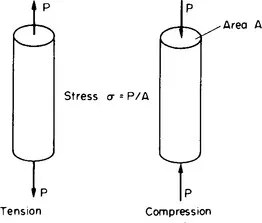

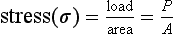

1.2 Direct or normal stress (σ)

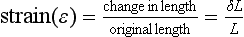

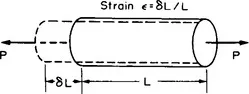

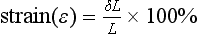

1.3 Direct strain (ε)

1.4 Sign convention for direct stress and strain

1.5 Elastic materials – Hooke’s law

Table of contents

- Cover image

- Title page

- Table of Contents

- Also of interest

- Copyright

- INTRODUCTION

- NOTATION

- Chapter 1: SIMPLE STRESS AND STRAIN

- Chapter 2: COMPOUND BARS

- Chapter 3: SHEARING FORCE AND BENDING MOMENT DIAGRAMS

- Chapter 4: BENDING

- Chapter 5: SLOPE AND DEFLECTION OF BEAMS

- Chapter 6: BUILT-IN BEAMS

- Chapter 7: SHEAR STRESS DISTRIBUTION

- Chapter 8: TORSION

- Chapter 9: THIN CYLINDERS AND SHELLS

- Chapter 10: THICK CYLINDERS

- Chapter 11: STRAIN ENERGY

- Chapter 12: SPRINGS

- Chapter 13: COMPLEX STRESSES

- Chapter 14: COMPLEX STRAIN AND THE ELASTIC CONSTANTS

- Chapter 15: THEORIES OF ELASTIC FAILURE

- Chapter 16: EXPERIMENTAL STRESS ANALYSIS

- APPENDIX 1: TYPICAL MECHANICAL AND PHYSICAL PROPERTIES FOR ENGINEERING METALS

- APPENDIX 2: TYPICAL MECHANICAL PROPERTIES OF NON-METALS

- APPENDIX 3: OTHER PROPERTIES OF NON-METALS

- INDEX

- Other Titles in the Series