eBook - ePub

Metal Foams: A Design Guide

- 251 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Metal Foams: A Design Guide

About this book

Metal foams are at the forefront of technological development for the automotive, aerospace, and other weight-dependent industries. They are formed by various methods, but the key facet of their manufacture is the inclusion of air or other gaseous pockets in the metal structure.

The fact that gas pockets are present in their structure provides an obvious weight advantage over traditionally cast or machined solid metal components. The unique structure of metal foams also opens up more opportunities to improve on more complex methods of producing parts with space inclusions such as sand-casting. This guide provides information on the advantages metal foams possess, and the applications for which they may prove suitable.

- Offers a concise description of metal foams, their manufacture, and their advantages in industry

- Provides engineers with answers to pertinent questions surrounding metal foams

- Satisfies a major need in the market for information on the properties, performance, and applications of these materials

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Chapter 1

Introduction

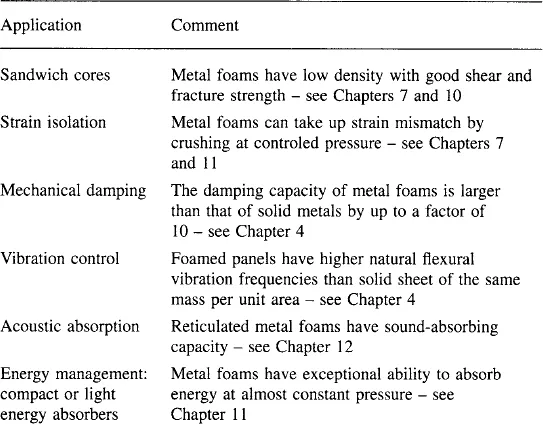

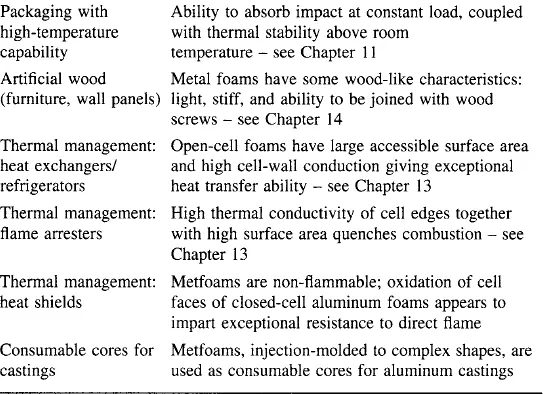

Metal foams are a new, as yet imperfectly characterized, class of materials with low densities and novel physical, mechanical, thermal, electrical and acoustic properties. They offer potential for lightweight structures, for energy absorption, and for thermal management; and some of them, at least, are cheap. The current understanding of their production, properties and uses in assembled in this Design Guide. The presentation is deliberately kept as simple as possible. Section 1.1 expands on the philosophy behind the Guide. Section 1.2 lists potential applications for metal foams. Section 1.3 gives a short bibliography of general information sources; further relevant literature is given in the last section of each chapter.

At this point in time most commercially available metal foams are based on aluminum or nickel. Methods exist for foaming magnesium, lead, zinc, copper, bronze, titanium, steel and even gold, available on custom order. Given the intensity of research and process development, it is anticipated that the range of available foams will expand quickly over the next five years.

1.1 This Design Guide

Metallic foams (‘metfoams’) are a new class of material, unfamiliar to most engineers. They are made by a range of novel processing techniques, many still under development, which are documented in Chapter 2. At present metfoams are incompletely characterized, and the processes used to make them are imperfectly controled, resulting in some variability in properties. But even the present generation of metfoams have property profiles with alluring potential, and the control of processing is improving rapidly. Metfoams offer significant performance gains in light, stiff structures, for the efficient absorption of energy, for thermal management and perhaps for acoustic control and other, more specialized, applications (Section 1.2). They are recyclable and nontoxic. They hold particular promise for market penetration in applications in which several of these features are exploited simultaneously.

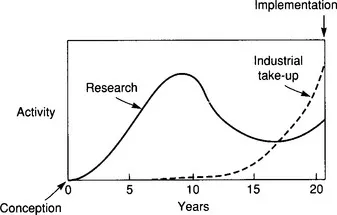

But promise, in today’s competitive environment, is not enough. A survey of the history of development of new material suggests a scenario like that sketched in Figure 1.1. Once conceived, research on the new material accelerates rapidly, driven by scientific curiosity and by the often over-optimistic predictions of its potential impact on engineering. The engineering take-up, however, is slow, held back by lack of adequate design data, experience and confidence; the disappointing take-up leads, after some 5 or 10 years, to disillusionment and a decline in research funding and activity. On a longer time-scale (15 years is often cited as the typical gestation period) the use of the new material – provided it has real potential – takes hold in one or more market sectors, and production and use expands, ultimately pulling research and development programmes with it.

Figure 1.1 A development history typical of many new materials. Research into the new material grows rapidly, and then slumps when little interest is shown by industry in using it. On a longer (15-year) time scale, applications slowly emerge

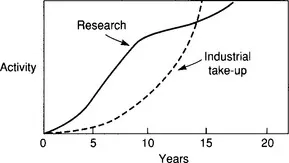

There are obvious reasons for seeking a better balance between research and engineering take-up. This Design Guide is one contribution to the effort to achieve faster take-up, to give development curves more like those of Figure 1.2. Its seeks to do this by

Figure 1.2 A more attractive development history than that of Figure 1.1. Early formulation of design rules, research targeted at characterizing the most useful properties, and demonstrator projects pull the ‘take-up’ curve closer to the ‘research’ curve

• Presenting the properties of metallic foams in a way which facilitates comparison with other materials and structures

• Summarizing guidelines for design with them

• Illustrating how they might be used in lightweight structures, energy-absorbing systems, thermal management and other application, using, where possible, case studies.

The Guide starts with a description of the ways in which metfoams are made (Chapter 2) and the methods and precautions that have evolved for testing and characterizing them (Chapter 3). It continues with a summary of material properties, contrasting those of metfoams with those of other structural materials (Chapter 4). Chapter 5 outlines design analysis for materials selection. This is followed in Chapter 6 by a summary of formulae for simple structural shapes and loadings; the ways in which the properties of metal foams influence the use of these formulae are emphasized.

Mechanical design with foams requires constitutive equations defining the shape of the yield surface, and describing response to cyclic loading and to loading at elevated temperatures. These are discussed in

Chapters 7, 8 and 9. One potential application for foams is that as the core for sandwich beams, panels and shells. Chapter 10 elaborates on this, illustrating how the stiffness and strength of weight-optimized sandwich structures compare with those of other types. Chapters 11, 12 and 13 outline the use of metal foams in energy, acoustic and thermal management. Chapter 14 describes how they can be cut, finished and joined. Chapter 15 discusses economic aspects of metal foams and the way economic and technical assessment are combined to establish viability. Chapter 16 reports case studies illustrating successful and potential applications of metal foams. Chapter 17 contains a list of the suppliers of metal foams, with contact information. Chapter 18 lists Web sites of relevant research groups and suppliers. The Guide ends with an Appendix in which material indices are catalogued.

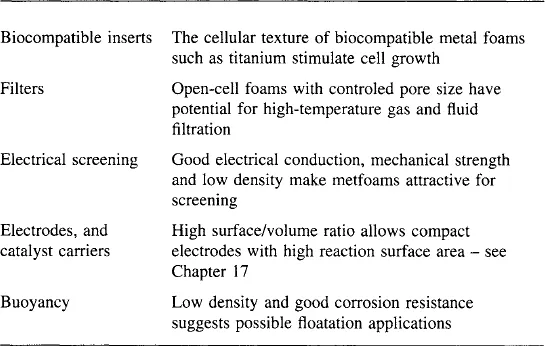

1.2 Potential applications for metal foams

1.3 The literature on metal foams

The body of literature on metal foams is small, but growing quickly. The selection below gives sources that provide a general background. Specific references to more specialized papers and reports are given at the end of the chapter to which they are relevant.

Banhart J., ed. Metallschäume. Bremen: MIT Verlag, 1997.

Banhart J., Ashby M. F., Fleck N. A., eds. Metal Foams and Foam Metal Structures, Proc. Int. Conf. Metfoam’99. ...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- Preface and acknowledgements

- List of contributors

- Table of physical constants and conversion units

- Chapter 1: Introduction

- Chapter 2: Making metal foams

- Chapter 3: Characterization methods

- Chapter 4: Properties of metal foams

- Chapter 5: Design analysis for material selection

- Chapter 6: Design formulae for simple structures

- Chapter 7: A constitutive model for metal foams

- Chapter 8: Design for fatigue with metal foams

- Chapter 9: Design for creep with metal foams

- Chapter 10: Sandwich structures

- Chapter 11: Energy management: packaging and blast protection

- Chapter 12: Sound absorption and vibration suppression

- Chapter 13: Thermal management and heat transfer

- Chapter 14: Electrical properties of metal foams

- Chapter 15: Cutting, finishing and joining

- Chapter 16: Cost estimation and viability

- Chapter 17: Case studies

- Chapter 18: Suppliers of metal foams

- Chapter 19: Web sites

- Appendix: Catalogue of material indices

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Metal Foams: A Design Guide by Michael F. Ashby,Tony Evans,NA Fleck,J.W. Hutchinson,H.N.G. Wadley,L. J. Gibson in PDF and/or ePUB format, as well as other popular books in Technologie et ingénierie & Science des matériaux. We have over one million books available in our catalogue for you to explore.