- 600 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Computer Vision Technology for Food Quality Evaluation

About this book

The first book in this rapidly expanding area, Computer Vision Technology for Food Quality Evaluation thoroughly discusses the latest advances in image processing and analysis. Computer vision has attracted much research and development attention in recent years and, as a result, significant scientific and technological advances have been made in quality inspection, classification and evaluation of a wide range of food and agricultural products. This unique work provides engineers and technologists working in research, development, and operations in the food industry with critical, comprehensive and readily accessible information on the art and science of computer vision technology. Undergraduate and postgraduate students and researchers in universities and research institutions will also find this an essential reference source.

- Discusses novel technology for recognizing objects and extracting quantitative information from digital images in order to provide objective, rapid, non-contact and non-destructive quality evaluation

- International authors with both academic and professional credentials address in detail one aspect of the relevant technology per chapter making this ideal for textbook use

- Divided into three parts, it begins with an outline of the fundamentals of the technology, followed by full coverage of the application in the most researched areas of meats and other foods, fruits, vegetables and grains

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

Part I

Fundamentals of Computer Vision Technology

Outline

1 Image Acquisition Systems

2 Image Segmentation Techniques

3 Object Measurement Methods

4 Object Classification Methods

1

Image Acquisition Systems

Mohd. Zaid Abdullah, School of Electrical and Electronic Engineering, Engineering Campus, Universiti Sains Malaysia, 14300 Penang, Malaysia

1 Introduction

In making physical assessments of agricultural materials and foodstuffs, images are undoubtedly the preferred method in representing concepts to the human brain. Many of the quality factors affecting foodstuffs can be determined by visual inspection and image analysis. Such inspections determine market price and, to some extent, the “best-used-before” date. Traditionally, quality inspection is performed by trained human inspectors, who approach the problem of quality assessment in two ways: seeing and feeling. In addition to being costly, this method is highly variable and decisions are not always consistent between inspectors or from day to day. This is, however, changing with the advent of electronic imaging systems and with the rapid decline in cost of computers, peripherals, and other digital devices. Moreover, the inspection of foodstuffs for various quality factors is a very repetitive task which is also very subjective in nature. In this type of environment, machine vision systems are ideally suited for routine inspection and quality assurance tasks. Backed by powerful artificial intelligence systems and state-of-the-art electronic technologies, machine vision provides a mechanism in which the human thinking process is simulated artificially. To date, machine vision has extensively been applied to solve various food engineering problems, ranging from simple quality evaluation of food products to complicated robot guidance applications (Tao et al., 1995; Pearson, 1996; Abdullah et al., 2000). Despite the general utility of machine vision images as a first-line inspection tool, their capabilities regarding more in-depth investigation are fundamentally limited. This is due to the fact that images produced by vision cameras are formed using a narrow band of radiation, extending from 10−4 m to 10−7 m in wavelength. For this reason, scientists and engineers have invented camera systems that allow patterns of energy from virtually any part of the electromagnetic spectrum to be visualized. Camera systems such as computed tomography (CT), magnetic resonance imaging (MRI), nuclear magnetic resonance (NMR), single photon emission computed tomography (SPECT) and positron emission tomography (PET) operate at shorter wavelengths ranging from 10−8 m to 10−13 m. Towards the opposite end of the electromagnetic spectrum there are infrared and radio cameras, which enable visualization to be performed at wavelengths greater than 10−6 m and 10−4 m, respectively. All these imaging modalities rely on acquisition hardware featuring an array or ring of detectors which measure the strength of some form of radiation, either following reflection or after the signal has passed transversely through the object. Perhaps one thing that these camera systems have in common is the requirement to perform digital image processing of the resulting signals using modern computing power. Whilst digital image processing is usually assumed to be the process of converting radiant energy in a three-dimensional world into a two-dimensional radiant array of numbers, this is certainly not so when the detected energy is outside the visible part of the spectrum. The reason is that the technology used to acquire the imaging signals is quite different, depending on the camera modalities. The aim of this chapter is therefore to give a brief review of the present state-of-the-art image acquisition technologies that have found many applications in the food industry.

Section 2 summarizes the electromagnetic spectrum which is useful in image formation. Section 3 describes the principles of operation of machine vision technology, along with illumination and electronics requirements. Other imaging modalities, particularly the acquisition technologies operating at the non-visible range, are briefly discussed in Section 4. In particular, technologies based on ultrasound, infrared, MRI and CT are addressed, followed by some of their successful applications in food engineering found in the literature. Section 5 concludes by addressing likely future developments in this exciting field of electronic imaging.

2 The electromagnetic spectrum

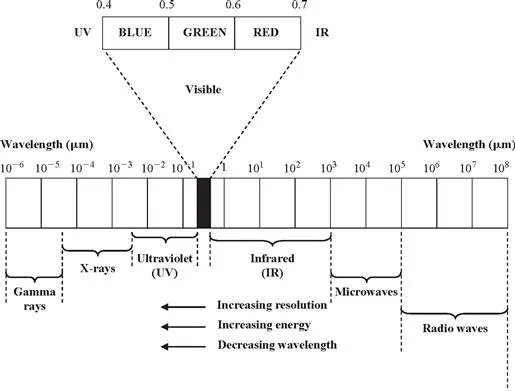

As discussed above, images are derived from electromagnetic radiation in both visible and non-visible ranges. Radiation energy travels in space at the speed of light in the form of sinusoidal waves with known wavelengths. Arranged from shorter to longer wavelengths, the electromagnetic spectrum provides information on the frequency as well as the energy distribution of the electromagnetic radiation. Figure 1.1 shows the electromagnetic spectrum of all electromagnetic waves.

Figure 1.1 The electromagnetic spectrum comprising the visible and non-visible range.

Referring to Figure 1.1, the gamma rays with wavelengths of less than 0.1 nm constitute the shortest wavelengths of the electromagnetic spectrum. Traditionally, gamma radiation is important for medical and astronomical imaging, leading to the development of various types of anatomical imaging modalities such as CT, MRI, SPECT, and PET. In CT the radiation is projected onto the target from a diametrically opposed source, whilst with others it originates from the target – by simulated emission in the case of MRI, and through the use of radiopharmaceuticals in SPECT and PET. At the other end of the spectrum, the longest waves are radio waves, which have wavelengths of many kilometers. The well-known ground-probing radar (GPR) and other microwave-based imaging modalities operate in this frequency range.

Located in the middle of the electromagnetic spectrum is the visible range, consisting of narrow portion of the spectrum with wavelengths ranging from 400 nm (blue) to 700 nm (red). The popular charge-coupled device or CCD camera operates in this range.

Infrared (IR) light lies between the visible and microwave portions of the electromagnetic band. As with visible light, infrared has wavelengths that range from near (shorter) infrared to far (longer) infrared. The latter belongs to the thermally sensitive region, which makes it useful in imaging applications that rely on the heat signature. One example of such an imaging device is the indium gallium arsenide (InGaAs)-based near-infrared (NIR) camera, which gives the optimum response in the 900–1700-nm band (Doebelin, 1996).

Ultraviolet (UV) light is of shorter wavelength than visible light. Similar to IR, the UV part of the spectrum can be divided, this time into three regions: near ultraviolet (...

Table of contents

- Cover image

- Title page

- Table of Contents

- Copyright

- About the Editor

- Contributors

- Preface

- Part I: Fundamentals of Computer Vision Technology

- Part II: Quality Evaluation of Meat, Poultry, and Seafood

- Part III: Quality Evaluation of Fruit and Vegetables

- Part IV: Quality Evaluation of Grains

- Part V: Quality Evaluation of Other Foods

- Index

- Food science and technology

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Computer Vision Technology for Food Quality Evaluation by Da-Wen Sun in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Computer Vision & Pattern Recognition. We have over one million books available in our catalogue for you to explore.