1.1. Motivation for the Integrated Design of Materials and Products

For millennia, the technological capabilities of societies have been so closely linked to available materials that entire eras—the Bronze Age and the Iron Age, for example—have been named for the most advanced engineered materials of the day. Even the modern Information Age owes its name to a revolution in information technology made possible by critical advances in Si-based semiconductors and other materials. The continuing technological advancement of our society is tied closely to our ability to engineer materials that meet the increasingly ambitious requirements of new products. In fact, advancement in materials technology is an enabling element of the exponential rate of technology development. In view of the acceleration of new technology development, it is no longer appropriate to categorize epochs according to material class; we live in an age of synthesis or integration of new and improved materials with electronics, our environment, and even our human bodies via medical implants. The notion of designing materials to best suit this integration is a relatively recent trend.

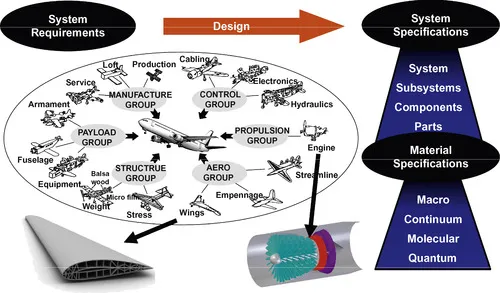

Design has been defined by the U.S. National Science Foundation (NSF) as a process by which products, processes, and systems are created to perform desired functions through specification. The fundamental objective in a design process is “to transform requirements—generally termed ‘functions,’ which embody the expectations of the purposes of the resulting artifact, into design descriptions” (Gero 1990). Complex new products and systems are currently realized with increasingly sophisticated and effective systems design techniques that have been shown to decrease product development cycle times and increase quality. Like the aircraft illustrated in Figure 1.1, many of these complex systems are realized by concurrently designing the subsystems, components, and parts into which a system is decomposed. However, the design process typically stops at the “part” level—rather than the “material” level—of the system hierarchy illustrated in Figure 1.1. Materials are typically selected—not designed—from a database of available options (Ashby 1999). Accordingly, the performance of many engineered parts and systems is limited by the properties of available constituent materials. For example, the further increase in efficiency and reduction in emission of aircraft gas turbine engines shown in Figure 1.1 requires high temperature, high strength, structural materials for the engine combustor liners, other hot section components, and gas turbine engine disks and blades. Unfortunately, these combinations of properties are not typically available from materials in current databases. The inherent difficulty with materials selection is the inability to tailor a material for application-specific requirements—such as those of the turbine engine hot section—that may conflict in terms of demands on material structure and properties. On the other hand, lead times for the development of new materials have remained relatively constant and unacceptably long relative to the desired product development cycle. The lengthy time frame and expense of new materials development is due in part to the predominantly empirical, trial-and-error approach adopted historically by materials engineers and developers (McDowell and Story 1998, Olson 2000).

A foundational premise for the field of materials design is that systems design techniques offer the potential for tailoring materials—as well as products that employ them—to serve the demands of multifunctional applications. We contend that the concept of materials design is not limited to selecting an available material from a database; instead, we actually tailor material structure at various levels of hierarchy (atoms, microstructure, etc.) via associated processing paths to achieve properties and performance levels that are customized for a particular application. In the materials science and engineering design communities, momentum is building toward materials design and away from exclusively empirical materials development approaches (McDowell and Story 1998). Materials scientists and engineers facilitate materials design by creating increasingly sophisticated, realistic, and accurate models for material structure and properties that can be used to support a design process to satisfy a ranged set of performance requirements. In addition, product and systems designers recognize the potential technological breakthroughs that can be achieved by concurrently designing materials and products, thereby overcoming the property and performance limitations of currently available materials for a host of applications.

At this point, it is useful to formalize a definition for the scope of concurrent design of materials and products, which we will refer to as materials design. The term materials design may have different meanings to different people and audiences. Accordingly, our definition is the top-down driven, simulation-supported, decision-based design of material hierarchy to satisfy a ranged set of product-level performance requirements.

It is quite clear that materials design is a challenging proposition. Materials are complex, multiscale systems with phenomena manifested at a hierarchy of length scales. Time scales range from atomic vibrations (femtoseconds) to relaxation of microstructure (nanoseconds to microseconds) to structural performance (seconds, hours, days, years).

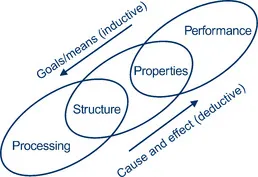

Materials design efforts therefore rely on continuous development and improvement of predictive models and simulations on a hierarchy of length scales, quantitative representations of structure, and effective archiving, management, and visualization of materials-related information and data. Together, these components provide important deductive links in the chain of processing-structure-properties-performance, as illustrated in Figure 1.2. Such deductive, bottom-up analytical tools are necessary but not sufficient for materials design. As discussed by Olson (Olson 1997) and illustrated in Figure 1.2, materials design is fundamentally an inductive, goal-oriented synthesis activity aimed at identifying material structures and processing paths that deliver required properties and performance. Like engineering systems design, it is a top-down exercise.

While Olson’s construct provides a foundation on which to build systems-based materials design, it does not fully illuminate the processes and strategies by which top-down design is to be carried out. Without an accompanying systems-based design strategy, it relegates practical aspects of inductive materials design to the creative will, depth of insight, experience, ability, and knowledge base of the individual designer. Important practical challenges must be addressed:

• Material structure and behavior is uncertain;

• Material models are uncertain and may be incomplete;

• Models are typically applied in bottom-up fashion, both for multiple scales of material structure and within the context of the linear deductive structure shown in Figure 1.2;

• Design goals change with time and adjust to new possibilities, such that the design process must be flexible and adaptable; and

• Materials engineers, analysts, and systems designers are distributed geographically within different organizations and have different backgrounds and expertise.

In view of the prevalent role of uncertainty, robust design methods are desirable. Effective, efficient, systems-based robust design methods are needed for modeling and executing complex, hierarchical materials design processes. A broad set of challenges and opportunities for concurrent design of materials and products is outlined in the report by the U.S. National Academy of Engineering National Materials Advisory Board on Integrated Computational Materials Engineering (ICME) (Pollock, Allison et al. 2008). These notions have gained considerable traction in industry. This book is devoted to exploring implications for systems strategies for concurrent design of materials and products, building on the foundations of Olson’s ideas embodied in Materials by Design® and ICME.