- 304 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

About This Book

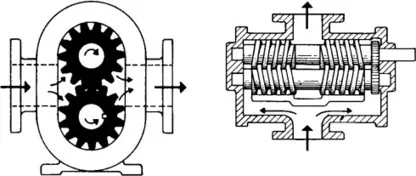

Working Guide to Pumps and Pumping Stations: Calculations and Simulations discusses the application of pumps and pumping stations used in pipelines that transport liquids. It provides an introduction to the basic theory of pumps and how pumps are applied to practical situations using examples of simulations, without extensive mathematical analysis. The book begins with basic concepts such as the types of pumps used in the industry; the properties of liquids; the performance curve; and the Bernoullis equation. It then looks at the factors that affect pump performance and the various methods of calculating pressure loss in piping systems. This is followed by discussions of pump system head curves; applications and economics of centrifugal pumps and pipeline systems; and pump simulation using the software PUMPCALC. In most cases, the theory is explained and followed by solved example problems in both U.S. Customary System (English) and SI (metric) units. Additional practice problems are provided in each chapter as further exercise. This book was designed to be a working guide for engineers and technicians dealing with centrifugal pumps in the water, petroleum, oil, chemical, and process industries.

- Calculations for their selection, sizing and power output

- Case studies based on the author's 35 years of field experience

- Covers all types of pumps

- Simplified models and simulations

Frequently asked questions

Information

Chapter 1 Introduction

- Radial flow pumps

- Axial flow pumps

- Mixed flow pumps

Table of contents

- Cover

- Title Page

- Copyright

- Dedication

- Preface

- Author Biography

- Chapter 1: Introduction

- Chapter 2: Pump Performance

- Chapter 3: Liquid Properties versus Pump Performance

- Chapter 4: Pressure Loss through Piping Systems

- Chapter 5: System Head Curves

- Chapter 6: Pump Performance at Different Impeller Sizes and Speeds

- Chapter 7: NPSH and Pump Cavitation

- Chapter 8: Pump Applications and Economics

- Chapter 9: Pump Simulation Using PUMPCALC Software

- Appendices

- References

- Index