eBook - ePub

The Quick Changeover Playbook

A Step-by-Step Guideline for the Lean Practitioner

This is a test

- 73 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Book details

Book preview

Table of contents

Citations

About This Book

This book covers the basics of setup reduction and quick changeover and data collection. It outlines the first pass of waste reduction through the implementation of the visual workplace and layout improvements. The book covers two quick changeover concepts: intermediate tooling and one-turn methods.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access The Quick Changeover Playbook by Chris A. Ortiz in PDF and/or ePUB format, as well as other popular books in Business & Operations. We have over one million books available in our catalogue for you to explore.

Information

Chapter 1

Setup and Quick Changeover

Introduction

Organizations that produce product in equipment-based environments should have setup reduction as a cornerstone of their Lean journey. A good understanding of the concepts and tools is needed as many people confuse the definitions of setup reduction and quick changeover. This chapter creates a baseline for understanding the concepts so you can be prepared to train and implement effectively with your team.

Downtime by definition is non–value added. It is the waste of waiting, as the machine is “waiting” to be turned on—whether from breakdowns, planned maintenance, or in the case of this playbook, for the setup to be complete.

Setup is the act of performing tasks at the end of a production run to the start of another production run. Changeover is part of the overall setup activities. To help explain, let us start with describing the four steps of a setup.

- Preparation

- Removing and mounting parts

- Measurements

- Trial runs and final adjustments

Preparation

- Retrieving material, supplies, and parts

- Reviewing paperwork

- Retrieving tools

- Retrieving tooling and fixtures

- Ensuring parts, tools, and tooling are functional and working properly

- Performing simple cleaning of equipment

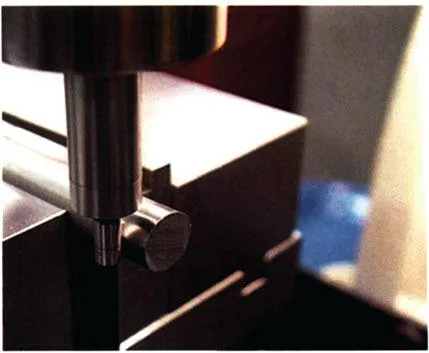

Removing and Mounting Components in Machine (Changeover)

- Disconnecting fixtures, part(s), and material

- Connecting fixtures, part(s), and material

- This step is the changeover.

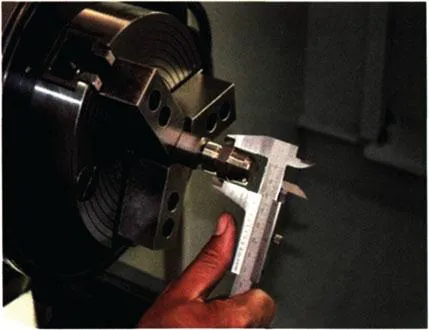

Measurements

- Measuring, calibrating to prepare for a production run

- Centering, dimensioning, measuring temperature/pressure, and so on

- Checking settings

Trial Runs and Final Adjustments

- Test piece to verify setup is complete

- Make adjustments as needed

- Potentially make a second test piece

Four Setup Steps

External and Internal Setup Steps

There are two different types of work performed during a setup: external and internal.

External

External work is performed when the machine is running. Generally when it is producing product, the machine operator is gathering items for the next production run. This is an id...

Table of contents

- Cover

- Title Page

- Table of Contents

- How to Use This Playbook

- Introduction

- Chapter 1: Setup and Quick Changeover

- Chapter 2: Data Collection

- Chapter 3: 5S and Layout Improvements

- Chapter 4: Intermediate Tooling and One-Turn Methods

- Chapter 5: Visual Management

- Chapter 6: After Improvements

- Conclusion

- Definition of Terms

- About the Author