![]()

Part I

Thermal Power Plant Control Process Performance and Energy Audits

![]()

1

Introduction to Improving Thermal Power Plant Efficiency

1.1 Power Plant Introduction

Although good success has been achieved in power generation from renewable energy and clean energy (wind, solar, etc.), conventional fossil fuel power plants still play a significant role in both developed and developing countries. Moreover, with the development of high-steam parameter powergeneration technology and carbon dioxide capturing technology, new fossil fuel power plants are becoming more efficient and environmentally friendly. A number of countries have constructed more new fossil fuel power plants because of the massive and stable unit power, low construction cost, and short construction period.

Figure 1.1 shows the boiler efficiency difference existing among various countries in the world [1]. The original design is the most important factor for boiler efficiency, for example, the efficiency of ultrasupercritical boilers is much higher than conventional subcritical boilers. However, the operation technology plays a significant role in improving boiler efficiency [2]. Boilers of identical design apparently firing identical fuels have often been reported to encounter quite different slagging and fouling problems [3]. This is the main reason why a number of famous international companies, such as ABB, Bailey, and Honeywell, provide their commercial software tools to optimize boiler efficiency in the power-generation industry [4]. In addition, almost every power-generation company in the world is making efforts to increase boiler efficiency and limit negative environmental emissions.

Artificial intelligence–based methods have been applied in a number of power stations to optimize the combustion process and increase efficiency [5, 6, 7, 8, and 9]. In addition, computational fluid dynamics (CFD) is used to model the complex combustion process, achieving successful assessment of boiler performance [10, 11, 12, 13, 14, and 15]. However, some combustion process-related problems, such as slagging and fouling, are still plaguing the electricity-generation industry by impairing boiler efficiency and increasing unplanned downtime caused by slagging blockage in critical components [16]. The main reasons for slagging and fouling are found to be both boiler design and operation. Moreover, with fuel quality frequently changing and critical boiler equipment gradually degrading, how to control an optimal flue gas and limit unburned carbon are significant to improving boiler efficiency [17].

1.2 Specific Problems of Fossil Fuel Boiler Combustion

Systematic analysis of the coal-fired boiler-combustion process uncovers three main influences of boiler efficiency. First, high-level slagging and fouling can massively reduce the heat-transfer rate of the water wall, superheater, or other heat-transfer equipment. Limiting slagging and fouling build-up can improve the combustion efficiency. Second, if the temperature or volume of exit gas is too high, more heat will be wasted by exit gas. Therefore, controlling the temperature and volume of exit gas can help achieve high efficiency. Finally, an unburnt gas or solid carbon is another negative factor to boiler efficiency. Decreasing unburnt carbon can effectively improve boiler combustion efficiency.

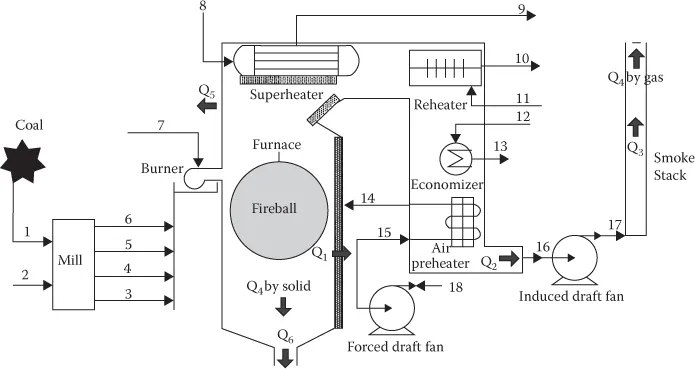

Figure 1.2 shows that fuel with specific characteristics is sent to the mill where the coal is pulverized and blown into the furnace of a boiler from burners by mixing with the primary air. Measurement point 1 can measure the amount of coal which is sent to mill, and point 2 can measure the amount of primary air which is mixed with coal powder. The coal-powder concentration can be measured at point 3. The flow speed of the mixture of air and coal powder can be measured at point 4. The temperature of the mixture of coal and air can be measured at point 5. The excess air rate can be measured at point 6. All the boiler input parameters can be adjusted and tuned in the control system, such as a programmable logic controller (PLC)-based control loop or distributed control system (DCS) in a power plant.

The burners are installed in the wall of furnace and the mixture of fuel and air is blown into the furnace to burn from burners. The secondary air is applied to adjust the flame shape of the fireball. It can be measured at point 7. With appropriate adjustment of the angle of burners, a rotated fireball can be formed in the furnace of the boiler. A high percentage of heat radiates to the surface of the water wall and the superheaters. At the same time, heat conduction occurs on the heat-transfer surface of all equipment inside the furnace. As the flow in the convection passes of furnace, the fluegas transports the residual heat outside the boiler. The overall process is shown in Figure 1.2. The saturated steam, which is heated in the boiler, drives the turbine with high enthalpy because of its high temperature and pressure. Measurement points 8 and 9 can measure the characteristics of the saturated steam in the primary and secondary superheaters. The reheater, economizer, and air preheater are installed in the flue gas pass to recover the residual heat. The temperature and pressure of the steam in the reheater can be measured at points 10 and 11. The temperature of feed water in the economizer is measured at points 12 and 13. The temperature of the primary air inside the reheater can be measured at points 14 and 15.

The residual flue gas blows out from the smoke stack and the temperature and pressure of the exit gas can be measured at point 16. A forced draft (FD) fan and induced draft (ID) fan keep a correct draft inside of the furnace. The power of the fans can be measured at points 17 and 18.

This is a simple, normal combustion process occurring inside the furnace of the boiler. However, the real combustion process is much more complex than this simple, normal process. A number of chemical reactions and physical activities, such as slagging deposition, corrosion, and erosion occurring on the heat-transfer surface, impair the efficiency of combustion. Therefore, a large amount of energy is lost and gases responsible for global warming are emitted.

1.3 Significance of the Research to Electrical Power Industry

PLCs, data acquisition systems, and DCSs, which primarily apply a proportional–integral–derivative (PID) control strategy based on input, state, and output variables in a measurable process, are widely applied in industry [18]. However, there are also some immeasurable processes in which a number of critical parameters are impossible to measure. For example, some parameters including slag thickness, slag accumulation, and corrosion rate are difficult to read using tra...