Control of Mechatronic Systems

Model-Driven Design and Implementation Guidelines

Patrick O. J. Kaltjob

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Control of Mechatronic Systems

Model-Driven Design and Implementation Guidelines

Patrick O. J. Kaltjob

About This Book

A practical methodology for designing integrated automation control for systems and processes

Implementing digital control within mechanical-electronic (mechatronic) systems is essential to respond to the growing demand for high-efficiency machines and processes. In practice, the most efficient digital control often integrates time-driven and event-driven characteristics within a single control scheme. However, most of the current engineering literature on the design of digital control systems presents discrete-time systems and discrete-event systems separately. Control Of Mechatronic Systems: Model-Driven Design And Implementation Guidelines unites the two systems, revisiting the concept of automated control by presenting a unique practical methodology for whole-system integration. With its innovative hybrid approach to the modeling, analysis, and design of control systems, this text provides material for mechatronic engineering and process automation courses, as well as for self-study across engineering disciplines. Real-life design problems and automation case studies help readers transfer theory to practice, whether they are building single machines or large-scale industrial systems.

- Presents a novel approach to the integration of discrete-time and discrete-event systems within mechatronic systems and industrial processes

- Offers user-friendly self-study units, with worked examples and numerous real-world exercises in each chapter

- Covers a range of engineering disciplines and applies to small- and large-scale systems, for broad appeal in research and practice

- Provides a firm theoretical foundation allowing readers to comprehend the underlying technologies of mechatronic systems and processes

Control Of Mechatronic Systems is an important text for advanced students and professionals of all levels engaged in a broad range of engineering disciplines.

Frequently asked questions

Information

1

Introduction to the Control of Mechatronic Systems

1.1 Introduction

1.2 Description of Mechatronic Systems

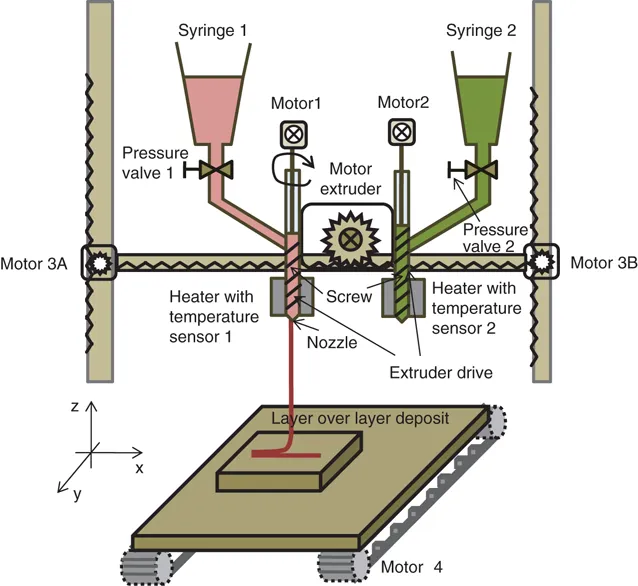

Example 1.1

- the angular position control of a pressure valve delivering semi-liquefied food (paste), the x-y axis position control of the carriage driving the extruder head (nozzle) made of two motors with a screw mechanism, the table angular speed and the z-axis position control;

- the heater temperature control (nozzle level);

- the remote pressure and force control for the valve in charge of injecting pressured food paste feed based on environmental (e.g. space mission) and biological conditions (e.g. lower gravity forces); and

- the logic control for the discrete selection of ingredients.

- Transportation-related processes, such as material handling processes, energy flow processes, and information transmission processes.

- Transformation-related processes, such as chemical processes, manufacturing processes, power generation, and storage processes.

- Processes characterized by a continuous flow of material or energy (e.g. cement drying process, electric ...