![]()

Chapter 1

Engine Block

The engine block is the foundation of any high-performance motor. It is the structure that holds everything together, but it has many other functions. Many people choose a block on the displacement sizing itself, but there are a slew of other factors that come into play when choosing the correct block to build upon.

Picking your engine block should be one of the first decisions made when building your desired engine. This isn’t 1998. There are now an abundance of choices in the block arena, both from factory sources and the aftermarket. Factors such as displacement, intended application, weight, and block strength all come into play. The most important reason to make your block decision early on is that it’s usually the first thing to be machined. You can change internal and external components later if you decide you made the wrong choice with the crankshaft, connecting rods, or pistons. Once the block is machined, however, you’re pretty much stuck with what it is. It’s something you want to get right the first time.

The LS-series family of blocks comes in a variety of materials and applications. Here, cast-iron blocks mingle with aluminum blocks while waiting to be bathed in honing oil.

DISSECTING THE GEN-III, A.K.A. THE “LS1”

The first Gen-III engines were the 5.7-liter aluminum-block engines known to the automotive crowd as the “LS1.” To obtain this displacement, the bore and stroke dimensions are a 3.898-inch bore with a 3.622-inch stroke. This is a highly popular engine to modify because all 1997–2004 C5 Corvettes, 1998–2002 F-bodies, and 2004 GTOs used this basic engine, helping give the Gen-III the reputation it has today.

There were a few minor variations made to the block as the LS1 progressed. One change was from the LS1 block to the revised LS6 block. All Corvette Z06s received LS6 block, and certain 2002 F-bodies did as well. The main differences between them are block material and improved crankcase breathing, which was necessary due to increased engine rpm ranges.

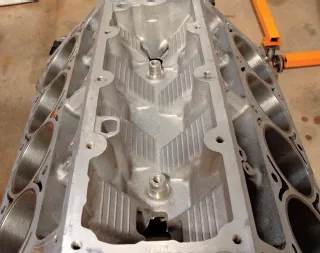

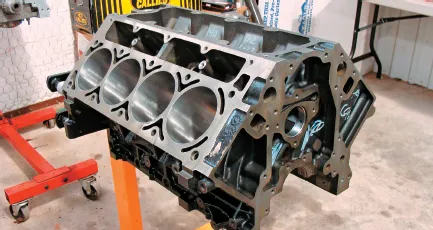

The LS1 5.7-liter has made a name for itself on the street and has a reputation for slaughtering many Mustangs and Cobras. This is the bare, no-frills, aluminum LS1 5.7-liter block. Its reputation precedes itself.

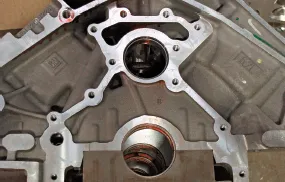

These little stands are actually the locations for the engine knock sensors (if used). Many would call this the lifter valley, but if you notice, you cannot replace the lifters without removing the cylinder heads themselves. This is a minor inconvenience.

The change from long head bolts to the medium-length head bolts that were used throughout all Gen-III engine designations in 2003–2004 model years is not well known. All F-bodies used the longer head bolts stock, unless equipped with a replacement engine, as the last F-body was manufactured in 2002, long before the head bolt revision.

The 1997 and 1998 LS1 5.7–liter blocks had thinner cylinder sleeves, so one drawback of these engines is they cannot tolerate a lot of cylinder machining. The limit for these blocks is 0.005-inch overbore, while all other 5.7–liter blocks are allowed 0.010 inch.

Popular engine displacements using the 5.7–liter block for buildup are the 347-cubic-inch (3.905-inch bore x 3.622-inch stroke), 383-cubic-inch (3.905-inch bore x 4.000-inch stroke), and 395-cubic-inch (3.905-inch bore x 4.125-inch stroke). With the right combination, these little engines can put up quite a fight and make very respectable horsepower numbers. A vast majority of fast LSX-based cars are using the stock block, and quite possibly the same stock short-block the car came with. The LS1 is highly efficient and surprisingly durable in stock form. Big cubic-inch engine owners beware of these wolves in sheep clothing; power-adder 5.7–liter engines can embarrass you easily if set up correctly.

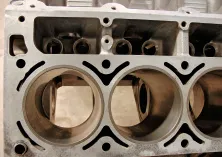

The aluminum block is poured around the cast sleeves, which have a small recommended machining limit compared to conventional iron blocks: 0.005 inch on 1998 blocks and 0.010 inch on 1999–2004 blocks. The lifters reside in plastic locating guides inboard the cylinders.

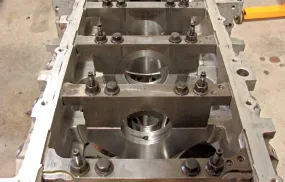

All LS-series engines come equipped with six-bolt main caps. The non-LS6 blocks used a gun-drilled hole above all mains that facilitated crankcase breathing.

Compare the LS6 block lower end’s cylinder-to-cylinder breathing window to the non-LS6 5.7-liter block in the previous photo. This window facilitates higher rpm crankcase breathing. Remember that whatever your displacement is above the piston, that same amount of air is being thrown about in the crankcase as well.

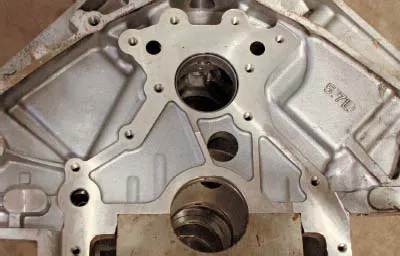

The oil travels from the oil filter directly to this point and makes a Y off toward each lifter oil gallery. The driver’s side oil gallery is responsible for feeding the lifters, the camshaft bearings, and the complete bottom end of the engine.

Here is the newer design lifter oil galley. Notice this area is now opened up to provide unrestricted oil flow to both lifter banks (compare to preceding image). This update equalizes any discrepancies in oil flow that may show up under demanding conditions.

Not long after the world was introduced to the aluminum 5.7-liter, the redesigned 1999 Chevrolet Silverado and GMC Sierra trucks were released. These were available with three different Gen-III engine variants at 4.8-liter, 5.3-liter, and 6.0-liter displacements. Though none were particularly impressive in stock form, the reason for mentioning them is that Gen-III engines have many interchangeable parts that are desirable donors for certain buildups.

All of the Gen-III engines are fairly stout in stock form. The one drawback to the truck motors in stock form is that the pistons are cast aluminum versus the LS1 and LS6 pistons, which are of the stronger hypereutectic design. The 4.8-liter and 5.3-liter blocks are identical other than the rotating assembly. The 5.3-liter and 6.0-liter share the same crankshaft stroke like its older 5.7-liter cousin. All of these early truck engine packages were cast-iron blocks. Later, some trucks received aluminum 5.3-liter engines similar to the 5.7-liter aluminum block. One thing to note about the 4.8-liter and 5.3-liter blocks is the cylinder wall thickness. They have enough material to be bored out 0.120-inch to stock LS1 displacement. So with the 4.8-liter or 5.3-liter block, one could have the same engine displacement as the aluminum 5.7-liter but with a cast-iron block.

The 6.0-liter block is the most sought-after truck donor block. In stock form, the 6.0-liter iron block is one stout setup. This block is readily available, and it’s the most economical to purchase if starting from scratch. It’s equipped with a conventional 4.000-inch bore and can go up to a 4.060-inch oversize easily, though 4.030 inches is the maximum recommended bore size for a power-adder setup. Many of these blocks have been built to produce more than 1,000 horsepower to the wheels. Popular displacements for the 6.0-liter block are the stock 364-cubic-inch setup (4.000 x 3.622 inches), 370-cubic-inch (4.030 x 3.622 inches), 402-cubic-inch (4.000 x 3.622 inches), and the ever-popular 408-cubic-inch (4.030 x 4.000 inches). A 422-cubic-inch engine can be built taking bore and stroke to the limits, although it’s unpopular to do so. Iron’s strength comes with the cost of weight, as this block is about 85 pounds heavier than the aluminum block.

INTRODUCTION TO GEN IV

The 5.7-liter lived a good life, but 2004 was its last year in production vehicles. In 2005, the Gen-IV engine became available, making even more engine choices available. Besides the larger cylinder bores, not a whole lot changed, but it still pays to be informed.

The 2005 C6 Corvette and GTO were made available with the 400-horsepower LS2 engine. This closely resembles an LS6 engine design, but it uses a larger 4.000-inch bore. There are a few external differences with the most significant being that the camshaft sensor reluctor is moved from the rear of the camshaft to the upper timing gear itself. This necessitated a different front timing cover and timing gear. Camshaft and knock sensor harness wiring extensions are available for vehicles not originally equipped with a Gen IV engine.

The iron LQ4/LQ9 is a stout foundation to build on. It has proven to hold up well beyond 1,000 rear wheel horsepower on numerous occasions. Standard bore is 4.000 inches, but it can reach a 4.060-inch bore for naturally aspirated applications; 0.030 inch is the recommended max for power-adders.