This is a test

- 380 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

Lubricant Analysis and Condition Monitoring

Book details

Book preview

Table of contents

Citations

About This Book

Almost all mechanical devices used in every industry require lubrication. Lubricant Analysis and Condition Monitoring explains the benefits of identifying, planning, implementing and using lubricant and machine condition monitoring programmes to extend the lifetimes of both lubricants and machines, to achieve maximum productivity and profitability while reducing impacts on waste and the environment.

This book:

-

- Offers a comprehensive overview of all types of tests used in lubricant condition monitoring programmes

-

- Discusses monitoring the condition of all types of components, machines, equipment and systems used in all industries

-

- Considers new and emerging machines, equipment and systems, including electric and hybrid vehicles

-

- Suggests which tests to use for each type of machine, equipment or system and, just as importantly, which tests not to use

-

- Provides practical examples of how to set up, run and manage condition monitoring programmes and how to achieve significant cost savings through planned and predictive maintenance schedules

Gathering vital information that users of lubricants need in one place, this book is of practical use to mechanical, maintenance, manufacturing and marine engineers as well as metallurgists, chemists and maintenance technicians.

Frequently asked questions

At the moment all of our mobile-responsive ePub books are available to download via the app. Most of our PDFs are also available to download and we're working on making the final remaining ones downloadable now. Learn more here.

Both plans give you full access to the library and all of Perlego’s features. The only differences are the price and subscription period: With the annual plan you’ll save around 30% compared to 12 months on the monthly plan.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 1000+ topics, we’ve got you covered! Learn more here.

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more here.

Yes, you can access Lubricant Analysis and Condition Monitoring by R. David Whitby in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Mechanical Engineering. We have over one million books available in our catalogue for you to explore.

Information

1 Introduction

DOI: 10.1201/9781003245254-1

1.1 Purpose

Almost all mechanical devices used in every industry require lubrication. Some machines, items of equipment or mechanical systems use very small amounts of lubricants, while others use huge quantities of oils and/or greases.

Examples of machines that use very little lubricants are personal computers (PCs) and laptops. In the past, many of these used a hard disc drive on which programs and data were stored. These hard discs had very small needle bearing that used a drop of a very high-performance lubricating oil. Now, PCs and laptops use solid-state storage media that do not need to be lubricated. However, both still need to use one or more cooling fans in order to keep the central processor and motherboard cool, and these still need tiny self-lubricated rolling bearings.Examples of machines that use huge quantities of lubricants are ocean-going container ships and crude oil tankers, as well as very large trucks and machines used in mining operations. A large hydraulic system might use ten tonnes of hydraulic oil, while a 500-megawatt steam turbine used to generate electricity might use 300 tonnes of turbine oil. Other items of equipment, such as the gearbox in a helicopter or the aviation gas turbine in a passenger aircraft, are critical to the operation of the helicopter or aircraft.

A huge range of different oils are used in machines and equipment of all types. The types of oils are listed in Table 1.1. Some of these types are not used as lubricants, but are functional fluids without which the machines or equipment could not operate. They are included in Table 1.1 because they are associated with the lubricants industry, either through their derivation from crude oil or natural gas or through their derivation from the chemicals industry.

| Automotive Oils | Industrial Oils | Other Oils |

|---|---|---|

| Gasoline engine oils for cars, vans and taxis | Industrial gear oils | Aviation gas turbine oils |

| Diesel engine oils for cars, vans and taxis | Hydraulic oils | Aircraft engine oils |

| Natural gas engine oils for cars vans and taxis | Fire-resistant hydraulic fluids | Two-stroke marine engine oils |

| Hydrogen engine oils | Steam turbine oils for electricity generation | Four-stroke marine engine oils |

| Gasoline engine oils for trucks and buses | Gas turbine oils for electricity generation | Water-mix metalworking fluids |

| Diesel engine oils for trucks and buses | Water turbine oils for electricity generation | Metalworking oils |

| Natural gas engine oils for trucks and buses | Wind turbine oils | Metal-forming oils |

| Hybrid and electric vehicle oils | Air compressor oils | Metal-forming pastes |

| Two-stroke engine oils for motorcycles | Gas compressor oils | Metal-drawing oils and pastes |

| Four-stroke engine oils for motorcycles | Refrigerator and air conditioner oils | Metal-stamping oils and pastes |

| Multipurpose engine oils for farm machinery | Textile oils | Transformer and switchgear oils |

| Automotive gear oils | Wire rope lubricants | Electrical cable oils |

| Automatic transmission fluids | Heat transfer oils | Electrical cable pastes and compounds |

| Shock absorber oils | Heat treatment oils and fluids |

Source: Pathmaster Marketing Ltd.

A slightly smaller range of greases, shown in Table 1.2, are used in numerous types of machines and equipment. All types of greases are used as lubricants, although they can have a number of other important functions, such as protecting against corrosion and ingress of water.

| Soap-Based Greases | Non-soap Greases |

|---|---|

| Lithium | Bentone (clay) |

| Lithium complex | Graphite (carbon black) |

| Calcium | Molybdenum disulphide |

| Calcium sulphonate | Polyurea (polymer) |

| Calcium complex | PTFE (polytetrafluoroethylene) |

| Aluminium | Silica |

| Aluminium complex | |

| Sodium | |

| Mixed soaps |

Source: Pathmaster Marketing Ltd.

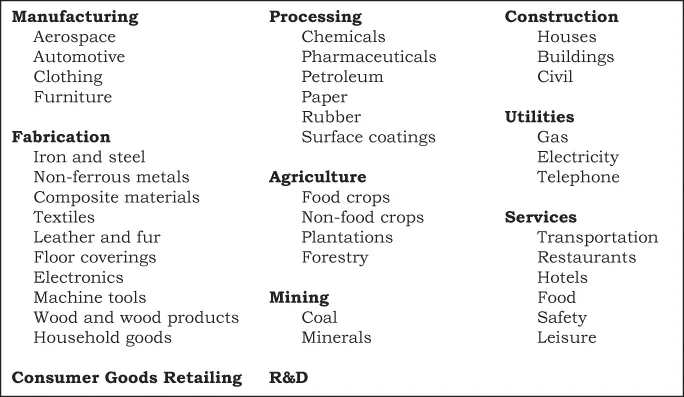

The range of industries in which these oils, greases and functional fluids are used is equally huge, as illustrated in Figure 1.1. The number of industries listed in Figure 1.1 is, in fact, a short list, as all of the headings have sub-headings and most of these have a number of sub-divisions. For example, although Research & Development (R&D) activities do not use big volumes of oils and greases, many of the items of equipment use small amounts of lubricants. Items such as ovens, refrigerators, mixers, robots, computers and testing machines all require lubrication in order to function.

FIGURE 1.1 Industry sectors.

Source: Pathmaster Marketing Ltd.

It is axiomatic that the condition of a lubricating oil or grease is likely to affect the functioning or lifetime of a machine, item of equipment or mechanical system. An oxidised or dirty lubricant is likely to cause increased wear or corrosion. Conversely, the age, operating conditions, design, location or construction of a machine, item of equipment or system is likely to affect the performance and lifetime of the oils and/or greases used as lubricants or functional fluids.

This is why monitoring the condition of both lubricants and machines is critically important to maximising the productivity, effectiveness, safety and profitability of both. An additional, and increasingly important, consideration is that lubricant and machine condition monitoring and predictive maintenance are likely to lessen waste and its impacts on the environment.

Fortunately, there are numerous sources of information and guidance about lubricant or machine condition monitoring and predictive maintenance. Most of these sources are in published magazines. For example, the magazine published by US Society of Tribologists and Lubrication Engineers (STLE), Tribology and Lubrication Technology (TLT), has regular articles about either lubricant condition monitoring or machine condition monitoring. Similarly, Noria Corporation publishes a monthly magazine Machinery Lubrication, which regularly contains articles about condition monitoring. Noria also publishes Lube Tips.

Noria also publishes a book, Oil Analysis Basics, a 192-page paperback that covers lubrication fundamentals, oil analysis and condition-based maintenance, contamination control, oil sampling methods, oil testing and analysis and targets, limits and data management. The second edition was published in 2010. However, this book does not appear to cover the monitoring of machines, equipment or systems in much depth.

Another book, Machinery Oil Analysis: Methods Automation and Benefits, a 506-page hardback published by the STLE in 2008, covers machinery lubrication, failure and maintenance concepts, machinery, fluid and filtration failure modes, oil sampling and testing and statistical analysis. However, this book does not appear to provide in-depth descriptions of oil and grease testing methods and explanations about which tests should and should not be used in a lubricant condition monitoring programme.

A third book, Machinery Condition Monitoring, Principles and Practices, published by CRC Press in 2017, is a “single source for practical machinery condition monitoring”. The book focusses on the mechanical side of condition monitoring, with chapters on vibration and rotor dynamics, noise monitoring, thermography, signal processing and instrumentation and wear debris analysis, for example. However, it does not include lubricant analysis and lubricant condition monitoring.

Other, much shorter books are focussed on specific topics, such as Wear Debris Analysis, Sourcebook for Used Oil Elements, Oil Sampling Procedures and In-Service Lubricant and Machine Analysis Diagnostics and Prognostics.

Companies that offer lubricant testing and advice on lubricant condition monitoring have pages on their websites that describe what services they provide. Some of this information is also provided in the form of downloadable pamphlets. For example, Bureau Veritas publishes a 32-page pamphlet The Basics of Oil Analysis, currently in its fifth edition. Obviously, these types of web pages and pamphlets are intended as a basic introduction to the subject and not a comprehensive guide. Users of lubricants that would benefit from comprehensive guidance will be able to obtain it from a lubricant testing company once they have signed up to a three- or five-year contract.

While there are many sources of information about lubricant and machine condition monitoring, they are currently scattered in many different places. Users of lubricants in machines, equipment and systems may need to spend some considerable time searching for the precise information relevant to them. The purpose of this book is, therefore, to gather all the information that users of lubricants may need, in one place, and to ensure that the information is both up-to-date and forward-looking.

It is important to note that a large number of lubricant and equipment tests are described in the following chapters. Many of these tests can and should be used in lubricant and machine monitoring programmes. However, other tests should not be used in lubricant and machine monitoring programmes, generally because they take too long to produce a result and/or because they are too costly to be of practical value. Many of these expensive or time-consuming tests are very valuable for developing new or improved lubricants, but they are not suitable when an important test result is required within one or two days. This book will explain which tests should be used for condition monitoring and which should not, and why.

It is also important to note here, however, that the test methods described in this book and used for lubricant and/or machine condition monitoring programmes are only those that are either standard test methods published by national and international organisations that develop and specify tests for lubricants or those that have been widely accepted by lubricant users. There are many test methods that have been developed and used by individual companies for their own purposes. While these tests may be of significant value to those companies, they have not yet been demonstrated to be of value to a larger number of companies. There are too many of them to be included in this book, although some of them may gain sufficient acceptance to be included in later editions.

It is envisaged that this book will be of practical use to companies and organisations that use significant amounts of lubricants, have large or expensive machines, or use equipment that is critical to the safe or profitable operation of the company or organisation.

Many users of lubricating oils and greases, such as individual motorists or truck drivers, are unlikely to find much value in reading this book. Some of these users may be interested to read this book, to discover more of the technology that goes into the safe and reliable operation of machines, equipment and systems. Owners and operators of large fleets of trucks, buses, trains and planes should find the contents of this book to be particularly useful and valuable.

1.2 Approach

All lubricants deteriorate in use. Consequently, they have a finite useful life. This useful life almost always depends on the conditions in which a lubricant is being used, together with the type and application of the machinery, equipment or system which is being lubricated. Arduous conditions, heavy loads, low or high speeds, constant stop-start or shock-loads will all contribute to shortening the useful life of a lubricant. It is axiomatic, therefore, that lubricants affect machines and machines affect lubricants.

Monitoring how and why lubricants deteriorate in use will enable a determination of when a lubricant has reached the end of its useful life and therefore needs to be changed. The primary criterion for the need to change a lubricant is when its further deterioration would lead to a situation in which it would be unable to protect the machinery or equipment from damage. There are several separate or joint causes for this.

In engines, for example, abrasive and corrosive materials can cause bearing damage, or bore polish, by removing the cross-hatched honing marks which maintain the lubricant film, or in extreme cases, “scuffing” of piston and bore.

These effects are often interdependent and will cause further changes either directly or through catalytic effects. When these lubricant deterioration effects occur in such complex systems as lubricant formulations, then a structured approach is needed to understand and solve the problem.

A lubricant condition monitoring programme will help significantly in determining when a lubricant is likely to reach or has reached the end of its useful life. At the same time, monitoring the condition of the machine, equipment or system in which the lubricant is being used will add to the determination of when the lubricant needs to be changed.

Chapter 2 describes and explores the requirements and benefits of analysing lubricants and monitoring their condition. The reasons for lubricant deterioration are explained, and the methods for setting up and operating a lubricant condition monitoring programme are discussed.

The first requirement for the effective analysis of lubricants is to obtain a representative sample. This involves using proper sample bottles, selecting and using the appropriate methods and techniques for taking samples and determining the optimum sampling location and frequency.

The objective of sampling is t...

Table of contents

- Cover

- Half Title Page

- Title Page

- Copyright Page

- Dedication

- Table of Contents

- Preface

- Author

- Chapter 1 Introduction

- Chapter 2 Reasons for Analysing Lubricants and Monitoring Their Condition

- Chapter 3 Sampling Lubricants

- Chapter 4 Testing New Lubricants

- Chapter 5 Testing Lubricants in Use

- Chapter 6 Chemical Tests for Lubricants

- Chapter 7 Physical Tests for Lubricants

- Chapter 8 Mechanical Rig Tests for Lubricants

- Chapter 9 Engine Tests for Lubricants

- Chapter 10 Condition Monitoring of Engines

- Chapter 11 Condition Monitoring of Gears and Transmissions

- Chapter 12 Condition Monitoring of Hydraulic Systems

- Chapter 13 Condition Monitoring of Compressors and Turbines

- Chapter 14 Condition Monitoring of Metalworking and Production Engineering Fluids and Pastes

- Chapter 15 Condition Monitoring of Automotive and Industrial Greases

- Chapter 16 Lubricant Condition Monitoring Programmes, Their Implementation, Benefits and How to Avoid Problems

- Glossary

- Index