![]()

1.1

Tree

More than 80,000 species of tree, ranging from arctic willows a few inches high to giant redwoods that can grow to over 300 feet tall, cover 30 percent of the Earth’s dry land.

Structure

Trees come in various shapes and sizes, but all possess the same basic structure. They have a central column, the trunk, which supports a framework of limbs, branches, and twigs. This framework is called the crown, and it is estimated that there are a finite number of branching systems for all tree species (around 30). Branches and twigs in turn have an outside covering layer of leaves. A tree is anchored in the ground using a network of roots, which spread and grow thicker in proportion to the growth of the tree above the ground.

All parts of the framework of a tree—trunk, branches, and twigs—are structural cantilevers with flexible connections at the junctions. All have the property of elastic behavior.

Hardwood and softwood: these terms refer to the types of tree from which the wood comes. Hardwood comes from deciduous forests; softwood from coniferous forests. Although hardwoods are generally of a higher density and hardness than softwoods, some (e.g. balsa) are softer.

Growth

Much of the energy produced by the leaves of a tree has to be diverted to make unproductive tissue (such as the woody trunk, branches, and roots) as the tree grows. The overwhelming portion of all trees (up to 99 percent) is made up of nonliving tissue, and all growth of new tissue takes place at only a few points on the tree: just inside the bark and at the tips of the twigs and roots. Between the outer (cambial) layer and the bark there is an ongoing process of creating sieve tubes, which transport food from the leaves to the roots. All wood is formed by the inner cambium and all food-conveying cells are formed by the outer cambium.

A tree trunk grows by adding a layer of new wood in the cambium every year. Each layer of new wood added to a tree forms a visible ring that varies in structure according to the seasons. A ring composed of a light part (spring growth) and a dark part (late summer/fall growth) represents one year’s growth. Timber used in construction is chosen on the basis of having an even balance of stresses within the plank. If a tree has grown on the side of a hill, it will grow stronger on one side and the stresses will be locked in to create a harder “red” wood that will eventually cause a plank to warp—by twisting or bowing.

Wind resistance

Trees are generally able to withstand high winds through their ability to bend, though some species are more resilient than others. Wind energy is absorbed gradually, starting with the rapid oscillation of the twigs, followed by the slower movement of the branches, and finally through the gently swaying limbs and trunk. The greater surface area of a tree in leaf makes it more susceptible to failing under wind load.

1

The basic structure of a tree

2

Section through a tree trunk a outer bark b inner bark c heartwood d cambium e sapwood

1.2

Spiderweb

Material properties

Spider silk is also known as gossamer and is composed of complex protein molecules. Chains of these molecules, with varying properties, are woven together to form a material that has an enormous capacity for absorbing energy. The silk of the Nephila spider is the strongest natural fiber known to man.

A general trend in spider-silk structure is a sequence of amino acids that self-assemble into a (beta) sheet conformation. These sheets stack to form crystals, whereas the other parts of the structure form amorphous areas. It is the interplay between the hard crystalline segments and the elastic amorphous regions that gives spider silk its extraordinary properties. This high toughness is due to the breaking of hydrogen bonds in these regions. The tensile strength of spider silk is greater than the same weight of steel; the thread of the orb-web spider can be stretched 30–40 percent before it breaks.

Silk production

Spiders produce silken thread using glands located at the tip of their abdomen. They use different gland types to produce different silks; some spiders are capable of producing up to eight different silks during their lifetime.

Web design and production

Spiders span gaps between objects by letting out a fine adhesive thread to drift on the breeze across a gap. When it sticks to a suitable surface at the far end, the spider will carefully walk along it and strengthen it with a second thread. This process is repeated until the thread is strong enough to support the rest of the web. The spider will then make Y-shaped netting by adding more radials, while making sure that the distance between each radial is small enough to cross. This means that the number of radials in a web is related directly to the size of the spider and the overall size of the web. Working from the inside out, the spider will then produce a temporary spiral of nonsticky, widely spaced threads to enable it to move around its own web during construction. Then, beginning from the outside in, the spider will replace this spiral with another, more closely spaced one of adhesive threads.

Impact resistance

The properties of spider silk allow it to be strong in tension, but also permit elastic deformation. When completed, the entire spiderweb is under tension; however, the elastic nature of the fibers enables it to absorb the impact of a fast-flying insect. On impact a local oscillation will occur, and the faster the oscillation the greater the resistance. This ability to store energy, and the fact that most of the energy is dissipated as the fiber deforms, allows spiders to intercept and catch their prey, by absorbing these creatures’ kinetic energy.

1

The spider’s silk-spinning glands

2

Sequence of web building

3

A giant spiderweb

4

The successful completion of an arrested landing on the flight deck of an aircraft carrier. The “checkmates” to which the aircraft becomes attached perform a similar kind of impact resistance to that of a spiderweb.

1.3

Eggshell

The structure of an eggshell varies widely among species but it is essentially a matrix lined with mineral crystals, usually a compound such as calcium carbonate. It is not made of cells, and harder eggs are more mineralized than softer ones.

Bird’s eggs—material properties

Birds are known for their hard-shelled eggs. The eggshell comprises approximately 95 percent calcium carbonate crystals, which are stabilized by an organic (protein) matrix. Without the protein, the crystal structure would be too brittle to keep its form.

Shell thickness is the main factor that determines strength. The organic matrix has calcium-binding properties and its organization during shell formation influences the strength of the shell: its material must be deposited so that the size and organization of the crystalline (calcium carbonate) components are ideal, thus leading to a strong shell. The majority of the shell is composed of long columns of calcium carbonate.

The standard bird eggshell is a porous structure, covered on its outer surface with a cuticle (called the bloom on a chicken egg), which helps the egg retain its water and keep out bacteria.

In an average laying hen, the process of shell formation takes around 20 hours.

Strength and shape

The structure of a bird’s eggshell is strong in compression and weak in tension. As weight is placed on top of it, the outer portion of the shell will be subject to compression, while the inner wall will experience tension. The shell will thus resist the load of the mother hen. Young chicks are not strong, but by exerting point-load forces on the inside of the shell they are able to break out unaided (the chick has an egg-tooth, which it uses to start a hole).

It is the arch/dome shape of the eggshell that helps it resist tension.

The strength of the dome structure of an eggshell is dependent on its precise geometry—in particular, the radius of curvature. Pointed arches require less tensile reinforcement than a simple, semicircular arch. This means that a highly vaulted dome (low radius of curvature) is stronger than a flatter dome (high radius of curvature). That is why it is easy to break an egg by squeezing it from the sides but not by squeezing it from its ends; staff members at the Ontario Science Centre in Toronto were successful in supporting a 200-pound person on an unbroken egg.

1

A chicken egg

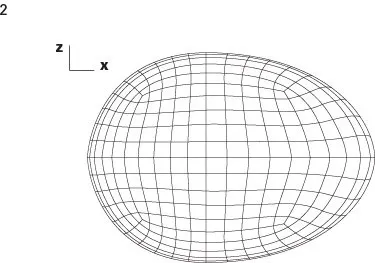

2

Generated eggshell mesh using shell-type elements

3

A microsco...