Extrinsic and Intrinsic Approaches to Self-Healing Polymers and Polymer Composites

- English

- ePUB (mobile friendly)

- Available on iOS & Android

Extrinsic and Intrinsic Approaches to Self-Healing Polymers and Polymer Composites

About This Book

Explore the cutting-edge in self-healing polymers and composites

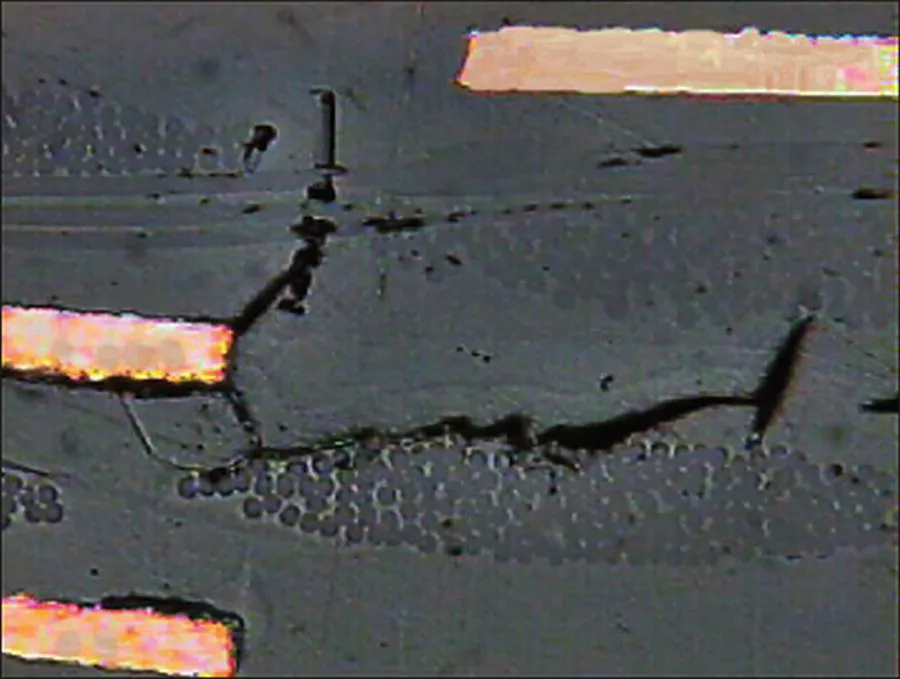

In Extrinsic and Intrinsic Approaches to Self-Healing Polymers and Polymer Composites, a pair of distinguished materials scientists delivers an insightful and up-to-date exploration of the fundamentals, theory, design, fabrication, characterization, and application of self-healing polymers and polymer composites. The book discusses how to prepare self-healing polymeric materials, how to increase the speed of crack repair, high temperature applications, and how to broaden the spectrum of healing agent species.

The authors emphasize the integration of existing techniques with novel synthetic approaches for target-oriented materials design and fabrication. They provide a comprehensive view of this emerging field, allowing new researchers to gather a firm understanding of the framework for creating new materials or applications. Additionally, the book includes:

- A thorough introduction to the field of self-healing polymers and polymer composites, including the advances made by various laboratories and the challenges, trends, and future directions that characterize modern research in the area

- Comprehensive explorations of the self-healing strategies proposed by the authors, including addition polymerization, systems-based microcapsules and plastic tubes, and more

- Practical discussions of the application of reversible S-S bonds in self-healing polymers

- In-depth examinations of intrinsic self-healing via reversible C-ON bonds

Perfect for polymer and materials scientists, chemists, and engineers, Extrinsic and Intrinsic Approaches to Self-Healing Polymers and Polymer Composites will also earn a place in the libraries of professionals working in the polymer, coatings, paints, medical, defense, and pharmaceutical industries.

Frequently asked questions

Information

1

Basics of Self‐Healing – State of the Art

CHAPTER MENU

- 1.1 Background

- 1.1.1 Adhesive Bonding for Healing Thermosetting Materials

- 1.1.2 Fusion Bonding for Healing Thermoplastic Materials

- 1.1.3 Bioinspired Self‐Healing

- 1.2 Intrinsic Self‐Healing

- 1.2.1 Self‐Healing Based on Reversible Covalent Chemistry

- 1.2.1.1 Healing Based on General Reversible Covalent Reactions

- 1.2.1.2 Healing Based on Dynamic Reversible Covalent Reactions

- 1.2.2 Self‐Healing Based on Supramolecular Interactions

- 1.2.2.1 Coordination Bonds

- 1.2.2.2 Ionic Associations

- 1.2.2.3 Hydrogen Bonds

- 1.2.2.4 Other Intermolecular Forces

- 1.2.2.5 Host–Guest Inclusion

- 1.3 Extrinsic Self‐Healing

- 1.3.1 Self‐Healing in Terms of Healant Loaded Pipelines

- 1.3.1.1 Hollow Tubes and Fibers

- 1.3.1.2 Three‐Dimensional Microvascular Networks

- 1.3.2 Self‐Healing in Terms of Healant Loaded Microcapsules

- 1.3.2.1 Methods of Microencapsulation

- 1.3.2.2 Healing Chemistries

- 1.4 Insights for Future Work

- References

1.1 Background

1.1.1 Adhesive Bonding for Healing Thermosetting Materials

Table of contents

- Cover

- Table of Contents

- Title Page

- Copyright Page

- Preface

- 1 Basics of Self‐Healing – State of the Art

- 2 Extrinsic Self‐Healing via Addition Polymerization

- 3 Extrinsic Self‐Healing Via Cationic Polymerization

- 4 Extrinsic Self‐Healing via Anionic Polymerization

- 5 Extrinsic Self‐Healing Via Miscellaneous Reactions

- 6 Intrinsic Self‐Healing Via the Diels–Alder Reaction

- 7 Intrinsic Self‐Healing Via Synchronous Fission/Radical Recombinationof the C─ON Bond

- 8 Intrinsic Self‐Healing Via Exchange Reaction of the Disulfide Bond

- Index

- End User License Agreement