![]()

CHAPTER 1

Why Build with Straw?

Straw bale builders must repeatedly answer the question, Why?

Why bother using straw bales? There are many answers, and we’ll start by addressing the most common reasons for building with bales.

Straw as a Building Material

Not a Building Newcomer

Despite its relatively new status as a building material in North America, straw has been used in construction for as long as humans have been creating shelter for themselves. Durable, flexible, and grown close to the building site, unbaled straw is still widely used around the world in a variety of roof, wall and flooring systems.

Straw in Block Form

The horse-driven baling machine, invented and introduced into the grain-growing regions of the North American West in the 1870s, had the unintentional side effect of turning mounds of loose straw into tight, easy-to-handle building blocks. The settlers of the Nebraskan sandhills, who faced a lack of lumber and suitable sod for building their new homes, were the first to put these building blocks to use. Some of these early bale structures are still standing and occupied — a testament to the durability of straw bale walls and the community spirit. The settlers’ enduring and effective homes are responsible for the bale building we do today.

1.1: The Pilgrim Holiness Church in Nebraska is one of the oldest surviving historical straw bale buildings. It’s a testament to the durability of bale buildings, and also the community spirit of this kind of construction.

dp n="17" folio="6" ? Straw Bales: The Waste that Rocked the World

Enough straw is currently produced every year in North America to meet all our residential building needs. And the same is true in many other parts of the world, since grain farming is common across most cultures and regions. This fact alone is enough reason to move toward using this abundant renewable resource for construction purposes, even if it held no particular advantage over other building materials. The fact that straw bale buildings can out-perform buildings made from other materials and lighten the load on the planet, as well as on our pocketbooks, makes it a triply effective material with which to build.

What’s in an “R”

Let me offer a slightly different take on what is likely happening with the R-value of a straw bale wall. I question whether the best, most controlled scientific testing would show anything like the R-50 that we have all heard about for [three-string, 24-inch-wide] straw bales. The test used gives a fair first approximation but is widely recognized as being less accurate than ASTM236 Hot Box testing. That said, the difference between R-30 and R-50 is really not that great. It is certainly less than the difference between R-10 and R-30, an apparently equally distant pair of values. This is because R-value, a number derived from U-factor, is the ability of a substance to resist heat flow. To understand how that plays out in actual performance, we need to convert R-values back to U-factors, the measure of how much heat flows through a substance under a predefined set of conditions. U-factor is 1.0 divided by R-value and vice versa.

An R-10 wall will allow 1/10 of one Btu (0.10 Btus) through one square foot of wall in an hour if there is a one-degree Fahrenheit temperature difference between the two sides of the wall. An R-30 wall will allow 1/30 of a Btu (0.033 Btus) through under the same conditions. An R-50 wall will allow 1/50 of a Btu (0.02 Btus) through. Obviously, if your wall is R-10, you are going to make a much bigger dent by increasing the R-value to R-30, than if your wall is R-30 and you move to R-50. It’s the law of diminishing returns. At some point, common sense and the pocketbook say it’s good enough.

However, the tested R-value has little to do with how the wall performs in the real world. This is much truer for straw bale walls than for stud walls. Thermal bridges occur with regularity in stud walls — in fact, at every stud. Straw bale walls have fewer thermal breaks, by far. Moreover, the R-value is measured under what can be called static conditions: you can only take your readings once the wall surface temperatures have stopped changing. This takes about 20 minutes for the average window, an hour or two for a wall, and three to seven days for a straw bale wall. In other words, the conditions at the two wall surfaces must not change for days on end, or the R-value is invalid. Well, how often in the real world does that happen with one’s house? The time it takes heat to travel through a straw bale wall is about 12 to 15 hours. By the time the heat has made that journey, diurnal (daily) temperature swings are driving the heat the other way in the wall. This means that a straw bale wall can give you the real-world impact of an R-50 wall, even though it is really only R-30.

— Nehemiah Stone built his own straw bale house in Penryn, California. The explanation above is adapted from his straw building list serve and presentations on thermal performance of straw bale homes.

Efficiency Benefits

Whether it’s a concern for the environment or for the bottom line of our monthly heating and cooling bills, the high level of energy efficiency achieved by straw bale homes is often the foremost reason for choosing straw bales over other building materials. The enviable energy efficiency is due to the good insulating properties of straw bales. The role of insulation is to minimize temperature loss or gain and therefore the amount of energy consumed to maintain a desired temperature. Through a combination of thickness, the amount of air they entrap, and the fairly low conductivity of straw itself, straw bales offer insulation values that can exceed those of modern, well-insulated, frame-walled homes.

Energy Consumption Comparison

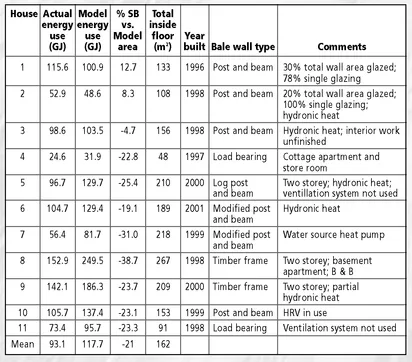

The Canada Mortgage and Housing Corporation funded a study overseen by British Columbia bale builder Habib Gonzalez. Using energy consumption data from BC bale homes, they were compared to equivalent frame-walled homes via computer modeling. The following is an excerpt from that report:

While straw bale houses have a theoretical energy saving advantage over conventional houses, there is little good data on how they actually perform. This survey attempted to provide a first cut at comparing the space-heating energy consumption of straw bale homes and conventional homes.

Many straw bale homes are wholly or partially heated with wood-burning appliances. As wood consumption is difficult to measure accurately, the 11 houses in this survey used other fuel sources — gas, oil, electricity.

Most surveys of this type compare the measured houses to “control” houses of the same size, construction quality, occupancy, etc. Control houses for this study were too hard to locate, given the diversity of straw bale house design and the use of slab-on-grade foundations. Only 3 of the 11 study homes had full or walkout basements. Instead of actual control houses, the energy use of the conventional houses was modeled using HOT2000 software. The measured space-heating consumption of the straw bale houses was compared to the modeled energy consumption of conventional 2001 British Columbia (BC) building code houses of the same dimensions as the straw houses.

1.2 CMHC Energy Consumption Comparison.

Research Program. The contractor located 11 straw bale houses that used measurable fuel types. He visited the houses, measured floor areas, windows, and doors, and examined the energy bills. From the bills, he was able to extract the energy used only for house space-heating, by subtracting the energy consumption of appliances, lighting, water heating, etc. Using the measurements of these houses, he created simulated houses built to current BC building codes and having 2-by-6 walls. All interior floor dimensions, floor insulation (if any), window dimensions, attic insulation, solar exposure, etc., were the same in the actual straw bale houses and the simulated conventional houses. The simulations used reinforced vinyl double glazed-windows with a half-inch air gap and insulated spacers, according to common BC construction practice, even if the windows of the straw bale houses were of a lesser quality. When the study home included windows with high-efficiency elements, such as low-E tints and argon gas, the modeled home windows matched these details. The simulation program used (HOT2000) has had wide application in the Natural Resources Canada (NRCan) R2000 program and in the Energuide for Houses retrofit program. It has been extensively tested and is typically within ten percent of measured data on individual houses, perhaps with a small bias to over-predict energy usage. When a number of houses are averaged, the resulting mean should be close to the truth. In cases where the same hot water heater was used for space heating and domestic hot water use (dishes, showering, etc.), the modeling of these houses (and the energy usage in Figure 1.2) included simulated hot water usage as well.

One qualifier: BC building code requires some form of mechanical ventilation be installed. The occupants of the straw bale houses may or may not have used the ventilation systems. In the simulated houses, an air change rate of 0.2 air changes per hour (ACPH) was used in the simulations to reflect both the natural infiltration rate and whatever use of mechanical ventilation. This is relatively low but still may be higher than the ventilation rates actually experienced in the straw bale homes. Similarly, the modeled house air leakage was set at 4.5 air changes per hour at 50 pascals (Pa), typical for new BC stock. There were no air-tightness tests of the straw bale houses. The 1.5-inch thick stucco skins on the inside and outside of the straw generally provide good air barriers (and add to the thermal mass of the wall construction).

Findings. House space-heating consumptions are listed in Figure 1.2. Electrical houses had their kWh readings changed to gigaJoules (GJ) to provide an easier comparison to houses using other fuels. The energy use listed is usually for space-heating only, with some exceptions, as described above.

The straw bale houses used over 20 percent less space heating energy when compared to the modeled conventional houses. Some of this may be due to under-ventilation of the straw bale houses and a small tendency for the model to over-predict energy consumption in the conventional houses. However, the size of the savings and the consistency (9 of 11 houses) indicates that the straw bale houses in this survey require significantly less space-heating energy than comparable conventional houses.

A version of this report appeared in The Last Straw, no. 41.

Habib John Gonzalez is the owner/operator of Sustainable Works, a British Columbia-based outfit offering straw bale home building services, plaster spraying, consulting, and workshops. Contact: Sustainable Works, 615B Cedar Street, Nelson, BC, Canada V1L 2C4, tel/fax 250.352.3731, <[email protected]>. The Canada Mortgage and Housing Corporation (CMHC) has funded a number of straw bale construction studies. The final version of this report (and others) can be downloaded at <http://www.cmhc-schl.gc.ca/publications/en/.rh-pr/t...