![]()

PART I

Classic High Pressure Sites

Classic microhydro sites look very much the way people expect water power technology to look. Towering mountains and rainy climates make microhydro a natural source of power. Here, gravity water systems are common and may be put to use making hydroelectricity for sale to the local grid, as they do in Chapters 1 and 4. More commonly, these sites power off-grid lodges and clubs (Chapters 2 and 3).

dp n="27" folio="2" ?dp n="28" folio="3" ? ![]()

1

Sustainable Skiing — Snowmass Ski Area Gets Hydro

AUDEN SCHENDLER

The histories of Aspen, Colorado, and hydroelectricity converge underground. Silver lodes drew the miners who first established Aspen. And Lester Pelton, the inventor of the modern waterwheel, was a gold miner in California. Both were pursuing a holy grail — vast wealth from the earth’s natural resources.

The silver miners found it in Aspen, once in the form of a 2,200 pound silver nugget. Pelton discovered no gold, but he extracted something more valuable — an efficient way to make clean energy from falling water. One hundred and forty years later, his invention, the Pelton wheel, is being put use in a ski resort near Aspen in a revolutionary way.

Sustainable Vision

The silver lodes are long since tapped out, but there is a new grail, of sorts, for the residents of this resort town. It is the idea of a sustainable community, one that can thrive with minimal impact on the environment. In the big picture, the main barrier to that vision is energy use.

As Vijay Vaitheeswaran points out in Power to the People, his superb book on global energy issues, “The needlessly filthy and inefficient way we use energy is the single most destructive thing we do to the environment.” The average US household is responsible for the annual emission of 23,380 pounds of carbon dioxide, the primary greenhouse gas, much of that from electricity use. Now, consider the emissions from plugging in a ski resort. And yet, “With enough clean energy,”

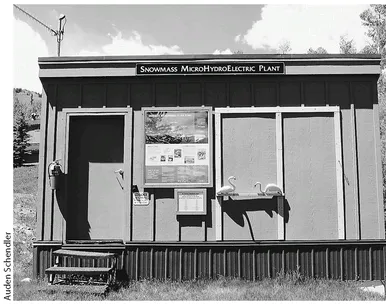

The microhydroelectric plant on Fanny Hill now has an educational display that will be viewed by an estimated 750,000 skiers annually.

dp n="29" folio="4" ?Vaitheeswaran notes, “most environmental problems — not just air pollution or global warming, but also chemical waste and recycling and water scarcity — can be tackled.”1

The Pelton Wheel

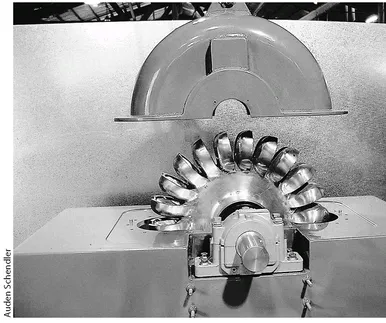

In 1864, when Lester Pelton worked in the mines, mechanical power came from waterwheels spun by jets of water. As the technology evolved, millwrights replaced wooden slats with metal cups, which turned the wheel faster. One day, Pelton observed a broken waterwheel. The jet was hitting the edge of the cup instead of the center. Pelton observed something else — the wheel turned faster than other wheels nearby. Based on his observations, Pelton developed a more efficient design and patented it. That design became the key component of many modern hydroelectric turbines. A Pelton wheel looks like an industrial flower or a blacksmith’s rendition of the universe. It is a beautiful and timeless tool, a reminder of human ingenuity that evokes the creativity of a silversmith more than the equations of an engineer. Pelton wheels have brought great affluence to the world through the sale and use of electricity — and great environmental damage through the construction of large dams. But the first wheel that Lester Pelton put to practical use ran his landlady’s sewing machine. Now, that legacy is helping to stitch together the fabric of a sustainable community.

Water from the turbine exits the tailrace.

Why Hydro?

Aspen Skiing Company, which operates four ski mountains — Aspen, Snowmass, Highlands and Buttermilk — and several hotels, is responsible for 28,000 tons of greenhouse gas pollution every year. Roughly 23,000 tons of that is from electricity use. One of the only ways to address this impact is to buy renewable electricity, which anyone (even homeowners) can purchase from the local utility, Holy Cross Energy.

The city of Aspen buys 67% of its electricity as renewables. Aspen Skiing Company buys wind power — about 5% of total usage — and increases its purchases annually. But the business can’t afford to buy renewables in the volume necessary to offset impacts, and the practice sometimes confuses guests. The most common question is, “Where’s the windmill?”

Installing a wind turbine on-site would be a significant investment. The best sites are far from transmission lines, on the local ridgetops. Areas closer to the transmission infrastructure are more sheltered, so there’s not enough wind. Photovoltaic panels are an option, but they’re expensive, especially for the quantity of energy required. However, one source of renewable energy on ski hills is plentiful, economical and readily at hand — water.

Early Aspen

Early Aspen was all hydro-powered. In fact, according to The Electric Review from January 1907, “Aspen led the way in the use of electricity for domestic lighting and mining. For years, it was the best-lighted town in the United States. It was the first mining camp to install an electric hoist, and the first to install generators run by water power.”

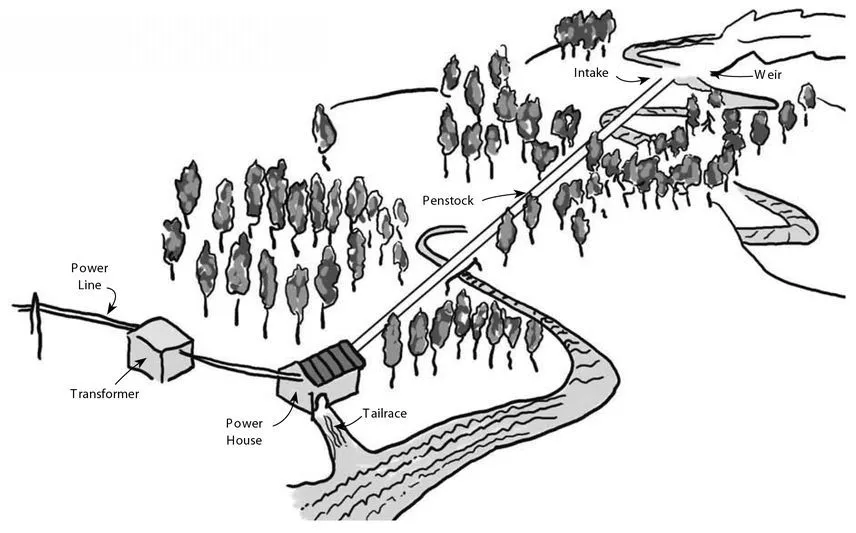

Today, three substantial microhydro systems are still running in the area (and likely many smaller ones). One is on Maroon Creek and puts out 450 to 500 kilowatts. A 20 kilowatt system is in the basement of the Mountain Chalet in Snowmass. And local micro-hydro enthusiast Tom Golec has a 40 kilowatt turbine on Ruedi Creek. Unlike dams, micro-hydro plants take some of the water out of the creek, but don’t have to block the flow. Such systems can generate electricity from relatively small streams — you don’t need to rebuild the Hoover Dam. The water runs through a pipe to the turbine and then back into the creek downstream.

A Not-So-Costly Installation

The biggest expense of most microhydro systems is the penstock, or pipe, that runs from high elevation to low, creating pressurized water that can spin the Pelton wheel. The economics of installing a penstock can often kill a project. At Snowmass Ski Area, installing a basic hydroelectric system would require building a retention pond (at a cost of about one million US dollars) and burying 4,000 feet of 10 inch steel pipe. The cost of such a project is mind-boggling. Once you add up pipe cost and excavation equipment time, you’re pushing a system’s payback into the next millennium. Unless, of course, you have the pipe and pond already in place. At the Snowmass Ski Area in Aspen, we do. We call it a snowmaking system.

Technical Specs

Location: Fanny Hill, Snowmass Ski Area, Snowmass, Colorado

Owner: Aspen Skiing Company

Project cost: US$155,000

Head: 746 feet

Pipeline length: 4,103 feet

Static pressure at turbine: 323 pounds per square inch

Average flow: 1,100 gallons per minute

Turbine: Single nozzle Pelton turbine from Canyon Hydro, 18.5 inch pitch diameter

Generator: 175 horsepower, 480 volt, three phase, 60 hertz, 115 kilowatt

Annual generation: 250,000 kilowatt-hours, estimated

The Pelton wheel used in the Snowmass Ski Area hydro plant was custom-made for the project by Canyon Hydro.

dp n="31" folio="6" ? Snowmass Microhydro System

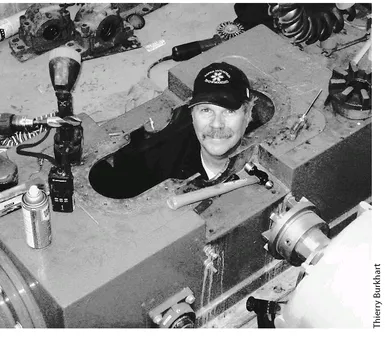

Frank White, doing repairs

Snowmaking pipes run everywhere at some ski resorts. So snowmaking supervisor Jimmy Holton asked, “If we already have half a hydroelectric system, why not just add a turbine and start making electricity?” We determined that a hydro plant could generate renewable energy at a fraction of the cost of using solar-electric panels. And the return on investment could be as low as seven years.

Snowmass Microhydro Costs

| Costs (in US$) | |

|---|

| Equipment | $65,610 |

| Turbine and switch gear, structure and foundation | $48,957 |

| Excavation, pipe connection and associated fees | $7,500 |

| Consulting fees | $7,240 |

| Flow meter | $6,000 |

| Electrician | $5,200 |

| Utility interface | $5,000 |

| Shipping | $3,000 |

| Installation and crane | $2,000 |

| Permits | $1,500 |

| Total Costs | $152,007 |

| |

| Grants | |

| CORE/REMP/Ruth Brown Fdn. | −$20,000 |

| OEMC | −$15,000 |

| StEPP | −$10,080 |

| Holy Cross | −$5,000 |

| Town of Snowmass Village | −$5,000 |

| Total Grants | $55,080 |

| |

| Grand Total Cost | $96,927 |

Convinced that a microhydro system was the best way to generate on-site renewable energy, Snowmass Ski Area built a small powerhouse on Fanny Hill, the beginner slope at the base of the mountain. The building houses a 115kilowatt turbine attached to a 10 inch steel snowmaking pipe that drains water from a storage pond which is 800 feet farther up the mountain and is fed by West Brush Creek. In 2005, our first complete year of operation, we made some 200,000 kilowatt-hours — enough to power 40 homes — while preventing the emission of 400,000 pounds of carbon dioxide.

A Turbine On Every Slope

Think about the possibilities. Hundreds of ski resorts in the US have snowmaking systems. On our four mountains alone, we have half a dozen more good opportunities for hydro. If we had 5 or 10 turbines running, we’d be generating an enormous amount of renewable energy — enough for say, 200 homes — contributing to clean air, stable climate and the long-term sustainability of the ski industry and the town. Any ski resort with a snowmaking system should look into installing a turbine. Inside each of those turbines, you’d find a Pelton wheel, a tool so elegant that it meets Einstein’s design criteria that everything should be made as simple as possible, but not simpler. It’s a device that has its origins tied to the origins of this town, and now, tied to its future as well.

Project Partners

The Snowmass hydroelectric project is so exciting and forward-looking, and has such broad applicability, that a wide range of partners were interested in providing financial supp...