- 216 pages

- English

- ePUB (mobile friendly)

- Available on iOS & Android

eBook - ePub

About this book

Metal Matrix Composites (MMC's) have found an increased use in various industries due to their special mechanical and physical properties. They are a composite material with at least two constituent parts, one being a metal and are made by dispersing a reinforcing material into a metal matrix. The markets are: telecommunications, automotive, power semiconductor, opto-electronics, military and aerospace, heavy transportation, space systems and satellites, medical, and industrial lighting. Applications within these markets include microwave, micro-electronic packaging, laser diode, HB-LED's, and advanced radar.

Tools to learn more effectively

Saving Books

Keyword Search

Annotating Text

Listen to it instead

Information

1 Metal matrix composites for thermal management

1.1 Introduction

In recent years some of the high-end technological applications related to the electronics industry have seen their advances clearly limited by the inherent inability to find new materials capable of matching the increasingly stringent requirements of this important branch of human development [1], [2]. Among the technological barriers that hinder the progress in electronics, we find the inability to remove the excessive heat produced during the operation of certain equipments. The amount of heat generated has been steadily increasing during the last decades due to the miniaturization of components and the consumption of increasing electrical power in electronic circuits. This heat, if it is not conveniently removed, can cause catastrophic failures by overheating or deformation of the structures due to a mismatch in the expansion coefficients of its elements [3], [4], [5], [6]. Finding materials capable of accomplishing these functions in sometimes extreme conditions (fast heating/cooling cycles, high humidity, etc.) is one of today’s major challenges in the electronics industry.

A material that is suitable for these purposes must combine two fundamental properties: it must have a high thermal conductivity (CT) (as high as possible – the required value has increased over time according to increasing needs) and a matched value of thermal expansion coefficient (CTE) (similar to that of semiconductors used in the manufacture of electronic circuits). Moreover, for each particular application, other extra properties can be mandatory: high chemical inertia, corrosion resistance, wear resistance, etc.

Nowadays, some of the most important achievements in materials science and technology come from developments of new materials capable of meeting the appropriate requirements to act as heat sinks for the electronics industry. Traditional heat sinks for electronics were made out of monolithic materials such as Al or Cu. However, these materials do not possess the right combination of properties for the current demands in electronics. The stringent requirements of high thermal conductivity and suitable CTE force the use of composite materials [7], [8]. Despite the enormous progress of composite materials in recent decades, there is still a need to develop new and better materials for these specific applications. Composite materials that have mostly been used as heat sinks in electronics are those derived from the Al/SiC family. These materials have shown, so far, a great combination of properties and represent the state of the art in heat sinking. However, the increasing property requirements make these materials disadvantageous for the near future and force the need to seek alternative materials. Among the candidates, there are some really promising materials under current development. In general, these are materials that combine a ceramic particulate reinforcement phase embedded in a metallic matrix [9]. Finely divided ceramic reinforcements have the advantages of easy handling and shaping in comparison with those formed by continuous fibers or laminar materials. The choice of a metal as the matrix seems to be beyond discussion because the temperatures of use of these heat sinks are high enough to cause the progressive degradation of the majority of polymers but, at the same time, sufficiently low in order not to choose ceramic matrices, which often leads to high manufacturing costs.

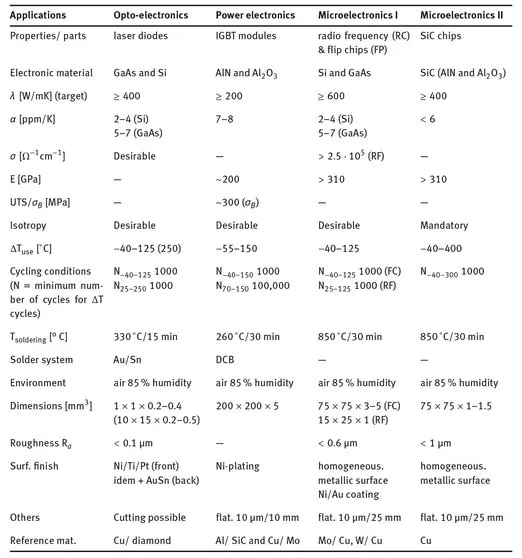

Table 1.1 gathers the most important properties required for different applications in the electronics industry for the future.

Table 1.1. Property requirements of the heat sinks needed for different applications in the electronics industry [10].

In this chapter we review the most promising families of composite materials that are being used or are considered suitable for use in the field of heat dissipation in the electronics industry.

1.2 Composite materials for thermal management

The two most important properties that are sought in heat dissipation are thermal conductivity and the thermal expansion coefficient. A material is considered or discarded for heat sinking depending, mainly, on the values of these two properties. The thermal conductivity should be the highest possible, in order to increase the capacity of heat transfer from the electronic device to the surrounding environment. The thermal expansion coefficient must lie in between very specific values (see Table 1.1). If it is too high or too low, the different elements of the electronic packaging will acquire different dimensions due to thermal expansion, and breakage caused by thermo-mechanical fatigue can occur.

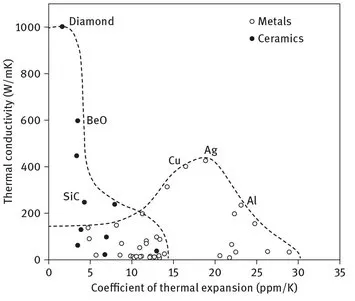

Ashby developed maps based on these criteria to help in the design of new materials for specific applications [11]. The maps applicable here show the property of thermal conductivity of various monolithic materials plotted as a function of their thermal expansion coefficients (see Figure 1.1).

Fig. 1.1. Map of the thermal conductivity and coefficient of thermal expansion for different metallic and ceramic materials.

In the previous map, the properties of large groups of metallic and ceramic materials are distinguished. Regarding metals, those having high values of thermal conductivity include Al, Ag and Cu (Au has an interesting thermal conductivity as well, but it is discarded due to its price). However, their thermal expansion coefficients are too high. That is why traditional heat sinks made out of monolithic metals are no longer used. On the other side, ceramics generally have lower thermal expansion coefficient values (in most cases too low) and many of them do also have high thermal conductivity. Among those having high thermal conductivity, we find diamond and SiC. BeO, despite its interesting properties, is excluded as a candidate because of its high toxicity. These ceramics could be used on their own for the production of heat sinks, but their clear drawback is the difficulty of machining them. Therefore it seems obvious that a metal-ceramic combination seems to be an appropriate proposal to solve the problem of heat dissipation in electronics.

The most interesting combinations arise from the mixture of these two ceramics, SiC and/or diamond, with metals such as Al, Ag or Cu. Properties expected for these combinations fall somewhere halfway between the properties of the metal and the ceramic. Therefore, with the aim to reduce the CTE and at the same time increase the CT as much as possible, combinations with a high volume fraction of these highly thermal conducting ceramic phases must be considered. The increased presence of ceramic in the composite material has some consequences of high technological relevance. On the one hand...

Table of contents

- Metal Matrix Composites

- Also of Interest

- Title Page

- Copyright Page

- Preface

- Table of Contents

- List of contributing authors

- 1 Metal matrix composites for thermal management

- 2 Recent research and developments on the mechanical behavior of CNT-reinforced metal matrix composites

- 3 Novel preparation and mechanical properties of in situ synthesized (TiB+La2O3)/TiNbTaZr composites

- 4 Microstructure formation of particle-reinforced metal matrix composite coatings produced by thermal spraying

- 5 Fabrication of Al-metal matrix composites by liquid stirring technique

- 6 Material removal processes for metal matrix composites

- 7 An investigation into machining Al/SiC metalmatrix composites

- 8 Application of response surface method and desirability function for the optimization of machining parameters of hybrid metal matrix (Al/SiC/Al2O3) composites

- Index

Frequently asked questions

Yes, you can cancel anytime from the Subscription tab in your account settings on the Perlego website. Your subscription will stay active until the end of your current billing period. Learn how to cancel your subscription

No, books cannot be downloaded as external files, such as PDFs, for use outside of Perlego. However, you can download books within the Perlego app for offline reading on mobile or tablet. Learn how to download books offline

Perlego offers two plans: Essential and Complete

- Essential is ideal for learners and professionals who enjoy exploring a wide range of subjects. Access the Essential Library with 800,000+ trusted titles and best-sellers across business, personal growth, and the humanities. Includes unlimited reading time and Standard Read Aloud voice.

- Complete: Perfect for advanced learners and researchers needing full, unrestricted access. Unlock 1.4M+ books across hundreds of subjects, including academic and specialized titles. The Complete Plan also includes advanced features like Premium Read Aloud and Research Assistant.

We are an online textbook subscription service, where you can get access to an entire online library for less than the price of a single book per month. With over 1 million books across 990+ topics, we’ve got you covered! Learn about our mission

Look out for the read-aloud symbol on your next book to see if you can listen to it. The read-aloud tool reads text aloud for you, highlighting the text as it is being read. You can pause it, speed it up and slow it down. Learn more about Read Aloud

Yes! You can use the Perlego app on both iOS and Android devices to read anytime, anywhere — even offline. Perfect for commutes or when you’re on the go.

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Please note we cannot support devices running on iOS 13 and Android 7 or earlier. Learn more about using the app

Yes, you can access Metal Matrix Composites by J. Paulo Davim in PDF and/or ePUB format, as well as other popular books in Technology & Engineering & Engineering General. We have over one million books available in our catalogue for you to explore.